Low-cost TMBS device structure and manufacturing method

A manufacturing method and device structure technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of silicon surface damage, poor reliability of use, complicated process steps, etc., and achieve reduced corrosion thickness and weakening. The effect of electric field concentration and area increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

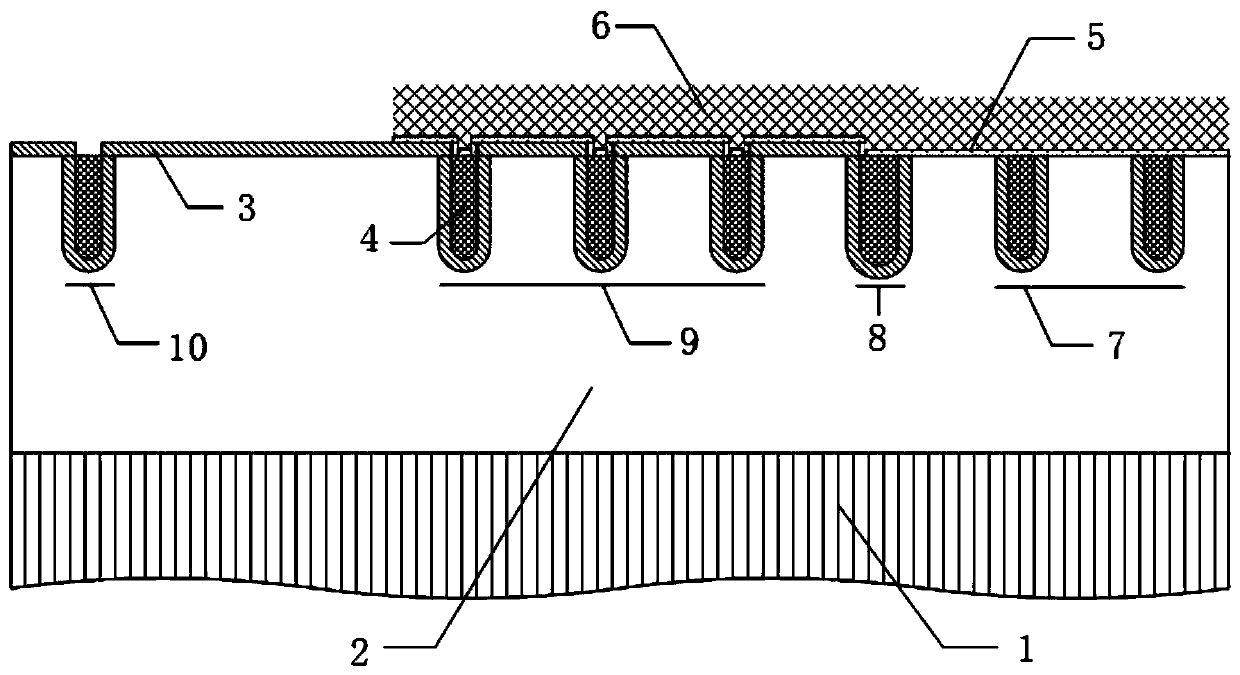

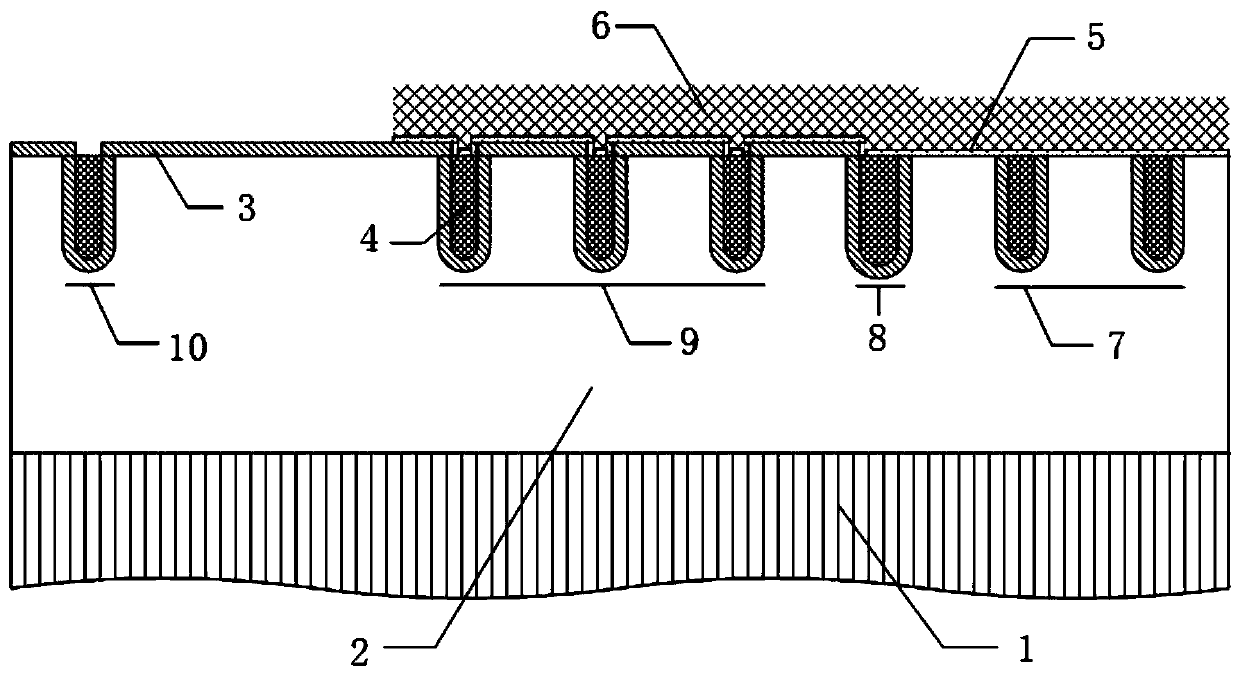

[0046] like figure 1 Shown, a kind of low-cost TMBS device structure among the present embodiment, it comprises as substrate densely doped silicon substrate 1; On densely doped silicon substrate 1, be provided with lightly doped silicon epitaxial layer 2; A silicon groove array is arranged on the silicon epitaxial layer 2, and the silicon groove array includes a cut-off groove 10, an extension groove 9, a large original cell groove 8, and several original cell grooves 7 arranged at horizontal intervals; each groove has Unused functions. A SiO2 layer 3 with a certain thickness is formed on the inner sidewall of the silicon trench array and the surface of the lightly doped silicon epitaxial layer 2; the interior of the silicon trench array is filled with heavily doped Poly4, and the top surface of the heavily doped Poly4 and the lightly doped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com