Polylactic acid microspheres and preparation method and application thereof

A polylactic acid microsphere, polylactic acid technology, which is applied in pharmaceutical formulations, medical science, prostheses, etc., can solve the problems of subcutaneous nodules or redness, poor controllability of particle size, complicated preparation process, etc. The effect of uniform diameter and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a kind of preparation method of polylactic acid microsphere, comprises the following steps:

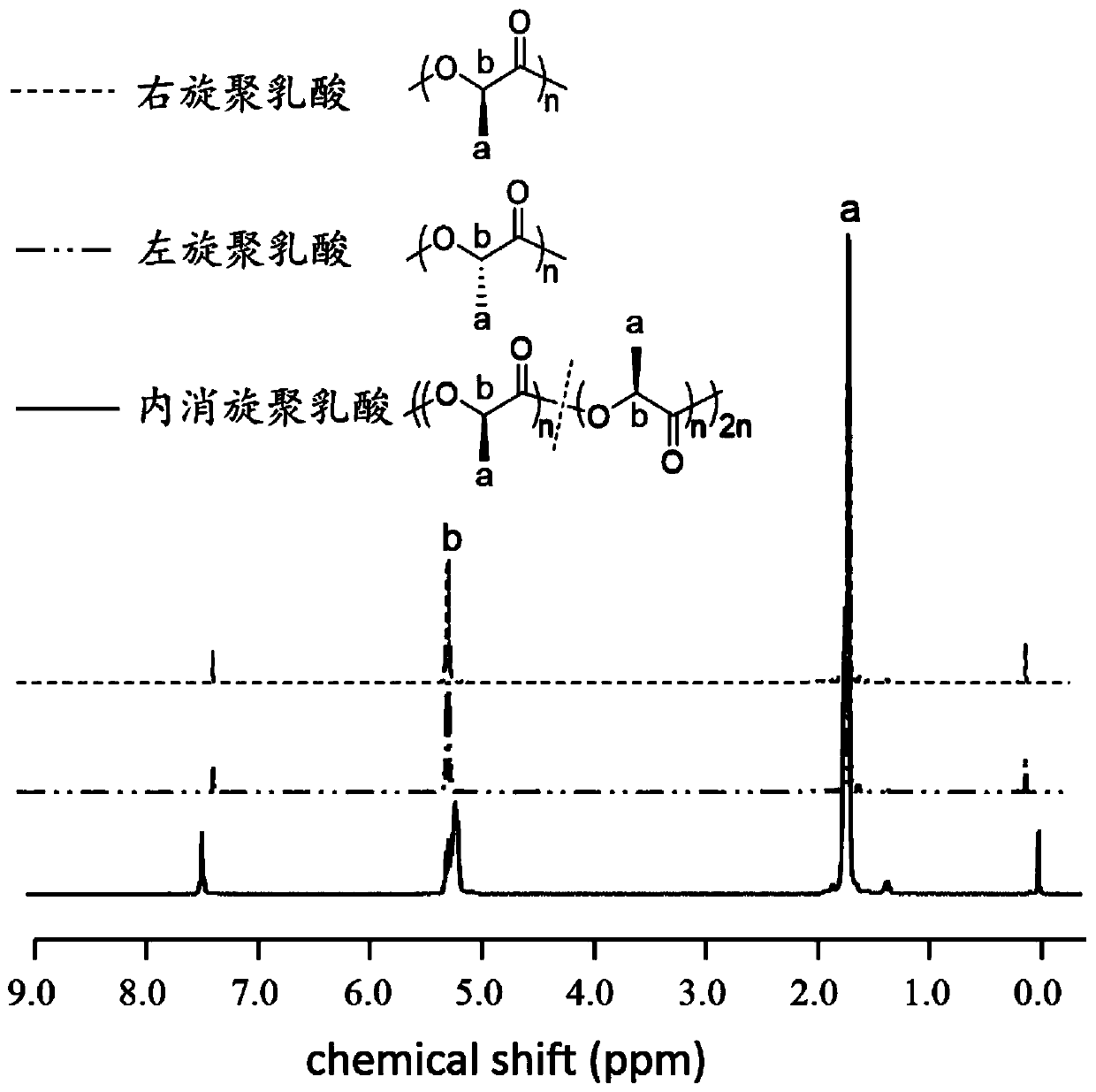

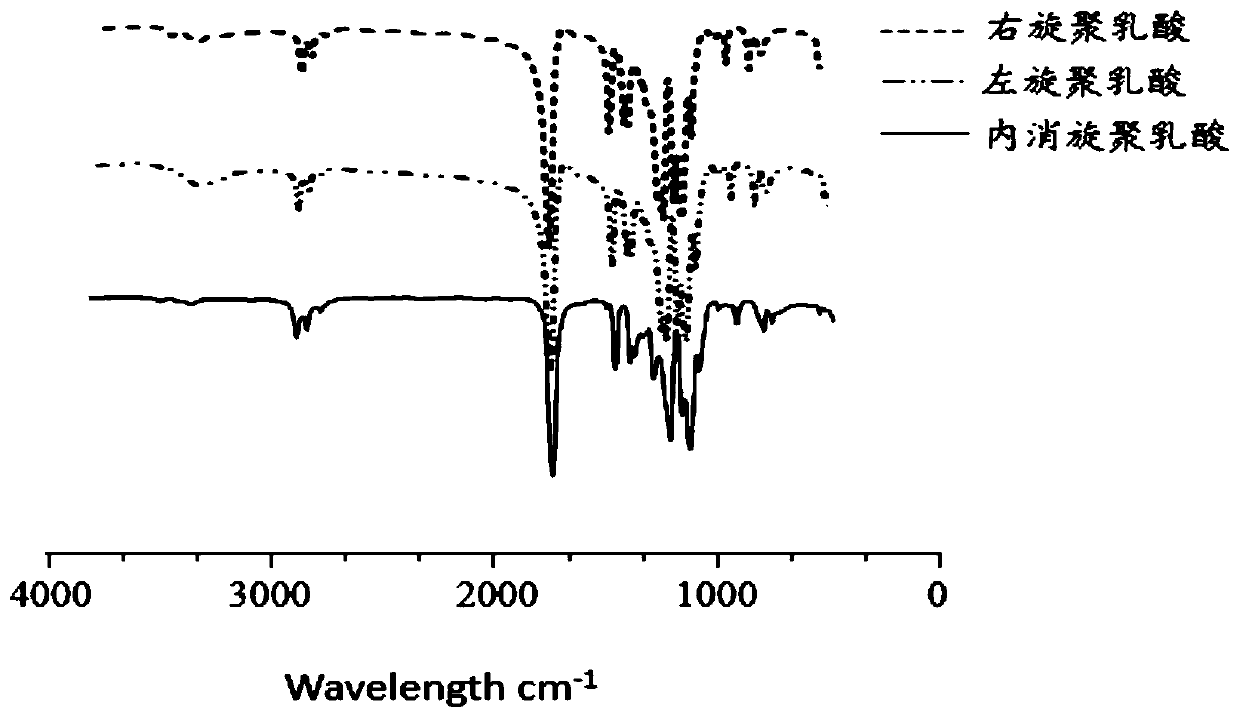

[0034] A) mixing polylactic acid and a solvent to obtain a polylactic acid solution; the polylactic acid includes L-polylactic acid, dextrorotary polylactic acid or mesogenic polylactic acid; the solvent includes methylene chloride;

[0035] B) mixing the polylactic acid solution with the polyvinyl alcohol solution, and performing high-speed shearing under ice-bath conditions to obtain an emulsion;

[0036] C) mixing the emulsion with water, removing the solvent, and freeze-drying to obtain polylactic acid microspheres.

[0037] In the invention, the polylactic acid is first mixed with a solvent to obtain a polylactic acid solution.

[0038] The polylactic acid includes L-polylactic acid, D-polylactic acid or mesogenic polylactic acid. The present invention has no special limitation on the source of the polylactic acid, which can be commercially availab...

Embodiment 1~12

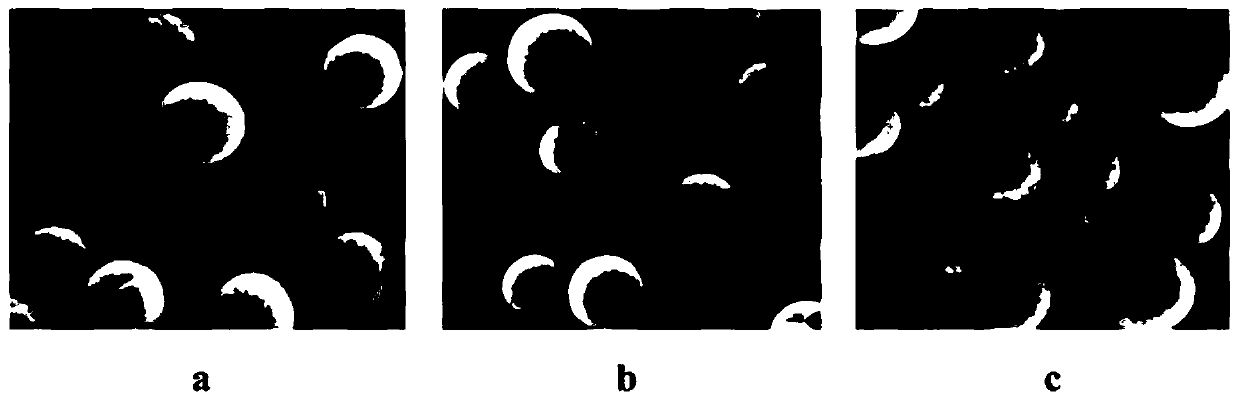

[0065] Embodiment 1~12: the preparation of polylactic acid microsphere

[0066] Dissolve 100 mg of L-polylactic acid, D-polylactic acid or mesopolylactic acid with a weight average molecular weight of 15000 g / mol in dichloromethane respectively to obtain polylactic acid solutions of different concentrations (10wt%, 5wt%, 3wt%, 2wt%, 1wt%);

[0067] Polylactic acid solutions of different concentrations were mixed with polyvinyl alcohol aqueous solutions with a concentration of 5wt% (the volume ratio of polylactic acid in the polylactic acid solution to polyvinyl alcohol in the polyvinyl alcohol solution was 1:5), and placed in an ice bath. High-speed shearing is carried out under conditions, the shear rate of the high-speed shear is 2000r / min, and the time of the high-speed shear is 3min, to obtain an emulsion.

[0068] The emulsion is mixed with ultrapure water, and the mixed solution is magnetically stirred, the speed of the magnetic stirring is 800r / min, and the time of mag...

Embodiment 13~24

[0072] Examples 13-24: Preparation of polylactic acid microspheres

[0073] Dissolving 100 mg of L-polylactic acid, D-polylactic acid or mesopolylactic acid with a weight average molecular weight of 15000 g / mol in dichloromethane respectively to obtain a polylactic acid solution with a concentration of 3 wt %;

[0074] The polylactic acid solution was mixed with polyvinyl alcohol aqueous solutions of different concentrations (0.25wt%, 2wt%, 5wt%, 8wt%, 10wt%) respectively (polylactic acid in the polylactic acid solution and polyvinyl alcohol in the polyvinyl alcohol solution The volume ratio of vinyl alcohol is 1:10), high-speed shearing is carried out under ice bath conditions, the shear rate of the high-speed shear is 2000r / min, and the time of the high-speed shear is 3min, to obtain an emulsion.

[0075] The emulsion is mixed with ultrapure water, and the mixed solution is subjected to magnetic stirring, the speed of the magnetic stirring is 1000r / min, and the time of magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com