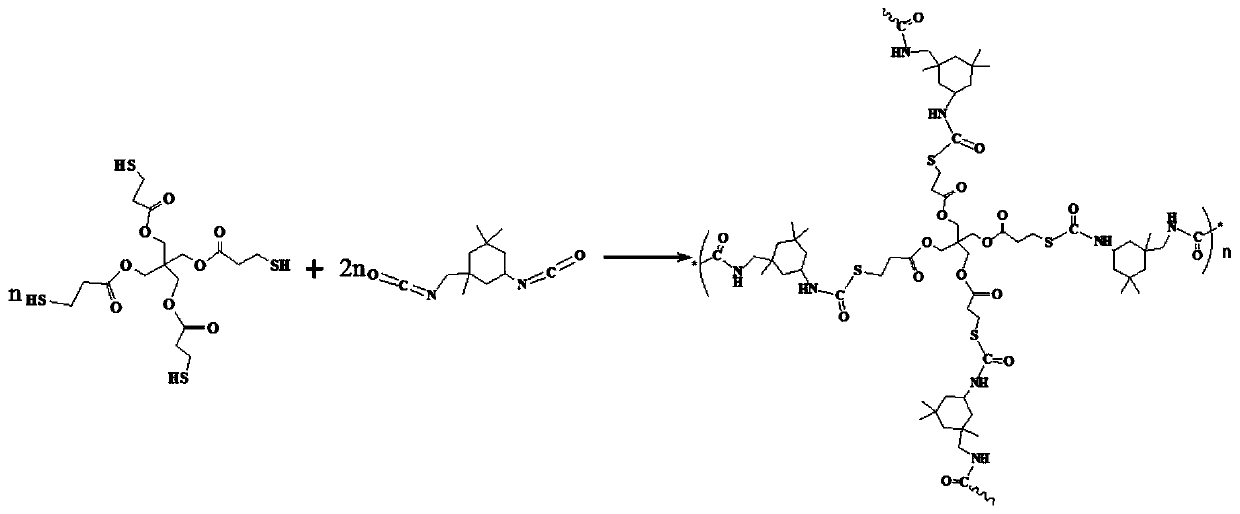

Method using click chemistry to prepare micron-sized functional porous polymer microspheres

A technology of porous polymer and click chemistry, which is applied in the field of preparation of polymer material microspheres, can solve the problems affecting the later application of microspheres, increasing the cost of material preparation, and less porous polymers, so as to facilitate large-scale industrial production, Easy surface functionalization and fast synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

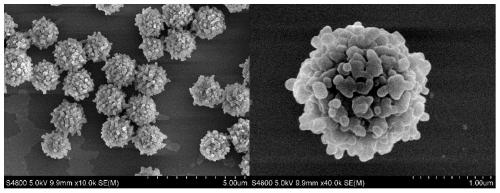

[0032] Embodiment 1: Add 5g polyvinylpyrrolidone (PVP), 1g chloroform (CHCl) successively in the container that magnetic stirrer is housed 3 ), 99g absolute ethanol, 1.53g pentaerythritol tetrakis (3-mercaptopropionate) ester (PETMP) and 1.38g isophorone diisocyanate (IPDI) simultaneously open agitator, rotating speed is 200rpm, and stirring time is 30min, stand Centrifuge after 6 hours, wash with absolute ethanol and water successively, freeze-dry and then freeze-dry porous polymer microspheres.

Embodiment 2

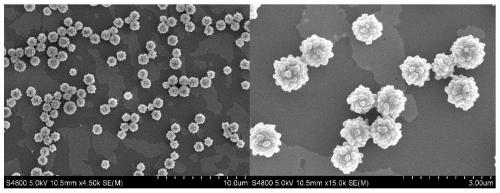

[0033] Embodiment 2: Add 5g polyvinylpyrrolidone (PVP), 2g chloroform (CHCl) successively in the container that magnetic stirrer is housed 3 ), 98g absolute ethanol, 1.53g pentaerythritol tetrakis (3-mercaptopropionate) ester (PETMP) and 1.38g isophorone diisocyanate (IPDI) simultaneously open agitator. The rotational speed is 200 rpm, the stirring time is 30 min, centrifuged after standing for 6 h, washed with absolute ethanol and water successively, freeze-dried and then freeze-dried to have porous polymer microspheres.

Embodiment 3

[0034] Embodiment 3: Add 5g polyvinylpyrrolidone (PVP), 3g chloroform (CHCl) successively in the container that magnetic stirrer is housed 3 ), 97g absolute ethanol, 1.53g pentaerythritol tetrakis (3-mercaptopropionate) ester (PETMP) and 1.38g isophorone diisocyanate (IPDI) simultaneously open agitator. The rotational speed is 200 rpm, the stirring time is 30 min, centrifuged after standing for 6 h, washed with absolute ethanol and water successively, and the porous polymer microspheres are freeze-dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com