UV roller painting black gloss finish paint and preparation process thereof

A black and bright technology, applied in the field of coatings, can solve the problems of incomplete curing of UV black and bright light, and achieve the effects of shortening the coating production cycle, low environmental pollution, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

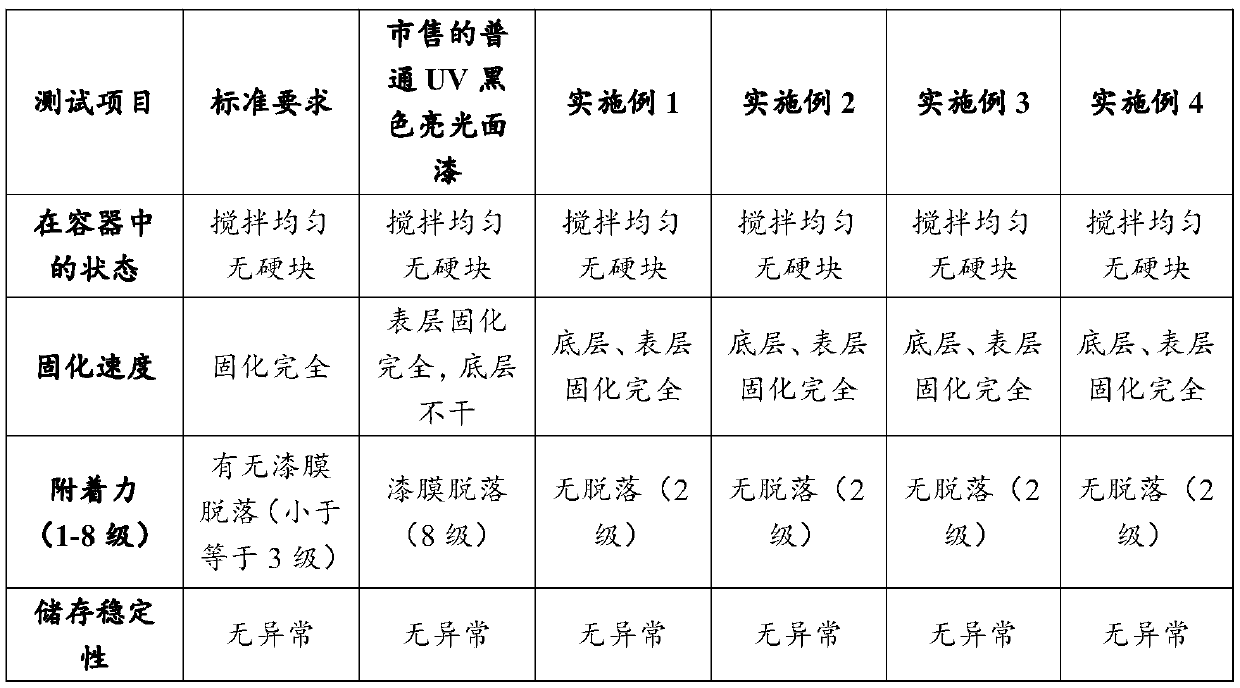

Examples

Embodiment 1

[0021] In parts by weight, the composition and content of a UV roller coating black gloss finish paint of the present invention are: 25 parts of polyurethane acrylate, 30 parts of standard epoxy acrylate, 1.5 parts of wetting and dispersing agent, and 0.1 part of defoaming agent , 0.4 parts of leveling agent, 8 parts of high-efficiency initiator, 9 parts of carbon black and 26 parts of functional monomer. Each raw material and reagent involved in above-mentioned a kind of UV roller coating black gloss topcoat are commercially available. Among them, Miki 6318 can be used for polyurethane acrylate; UV6002 of our factory can be used for standard epoxy acrylate; BYK168 can be used for wetting and dispersing agent; Tego920 can be used for defoaming agent; BYK361 can be used for leveling agent; Degussa can be used for carbon black FW200. In addition, in terms of parts by weight, among the functional monomers, there are 6 parts of di-trimethylolpropane tetraacrylate, 8 parts of trip...

Embodiment 2

[0028] In parts by weight, the composition and content of a UV roller coating black gloss finish paint of the present invention are: 23 parts of polyurethane acrylate, 32 parts of standard epoxy acrylate, 1 part of wetting and dispersing agent, and 0.15 parts of defoaming agent , 0.35 parts of leveling agent, 7 parts of high-efficiency initiator, 8 parts of carbon black and 28.5 parts of functional monomer. Each raw material and reagent involved in above-mentioned a kind of UV roller coating black gloss topcoat are commercially available. Among them, Miki 6318 can be used for polyurethane acrylate; UV6002 of our factory can be used for standard epoxy acrylate; BYK168 can be used for wetting and dispersing agent; Tego920 can be used for defoaming agent; BYK361 can be used for leveling agent; Degussa can be used for carbon black FW200. In addition, in terms of parts by weight, among the functional monomers, there are 5 parts of di-trimethylolpropane tetraacrylate, 7 parts of tr...

Embodiment 3

[0035] In parts by weight, the components and contents of a UV roller coating black gloss finish paint of the present invention are: 20 parts of polyurethane acrylate, 35 parts of standard epoxy acrylate, 1 part of wetting and dispersing agent, and 0.05 part of defoaming agent , 1 part of leveling agent, 6 parts of high-efficiency initiator, 9 parts of carbon black and 37 parts of functional monomer. Each raw material and reagent involved in above-mentioned a kind of UV roller coating black gloss topcoat are commercially available. Among them, Miki 6318 can be used for polyurethane acrylate; UV6002 of our factory can be used for standard epoxy acrylate; BYK168 can be used for wetting and dispersing agent; Tego920 can be used for defoaming agent; BYK361 can be used for leveling agent; Degussa can be used for carbon black FW200. In addition, in terms of parts by weight, among the functional monomers, there are 10 parts of di-trimethylolpropane tetraacrylate, 5 parts of tripropy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com