Polyacrylonitrile fiber pre-oxidation method, polyacrylonitrile carbon fiber and preparation method thereof

A technology of polyacrylonitrile carbon fiber and polyacrylonitrile fiber, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc. It can solve the problems of high energy consumption, long residence time, and slow running speed of polypropylene fiber in the pre-oxidation process, and realizes Effects of rapid pre-oxidation, improved performance stability, and shortened pre-oxidation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] On the other hand, the embodiment of the present invention also provides a method for preparing polyacrylonitrile carbon fiber, which is characterized in that it comprises the following steps:

[0066] Pre-oxidation: Pre-oxidize the polyacrylonitrile fiber in a pre-oxidation device to obtain a pre-oxidized fiber body; wherein, the above-mentioned pre-oxidation method for polyacrylonitrile fiber is used to perform a pre-oxidation reaction on the polyacrylonitrile fiber;

[0067] Low-temperature carbonization: performing low-temperature carbonization on the pre-oxidized fiber body to obtain a low-temperature carbonized fiber body;

[0068] High-temperature carbonization: Carry out high-temperature carbonization on the low-temperature carbonized fiber body to obtain polyacrylonitrile carbon fibers.

[0069] Preferably, the step of low-temperature carbonization is as follows: enter the pre-oxidized fiber body into a low-temperature carbonization furnace, and carry out low-t...

Embodiment 1

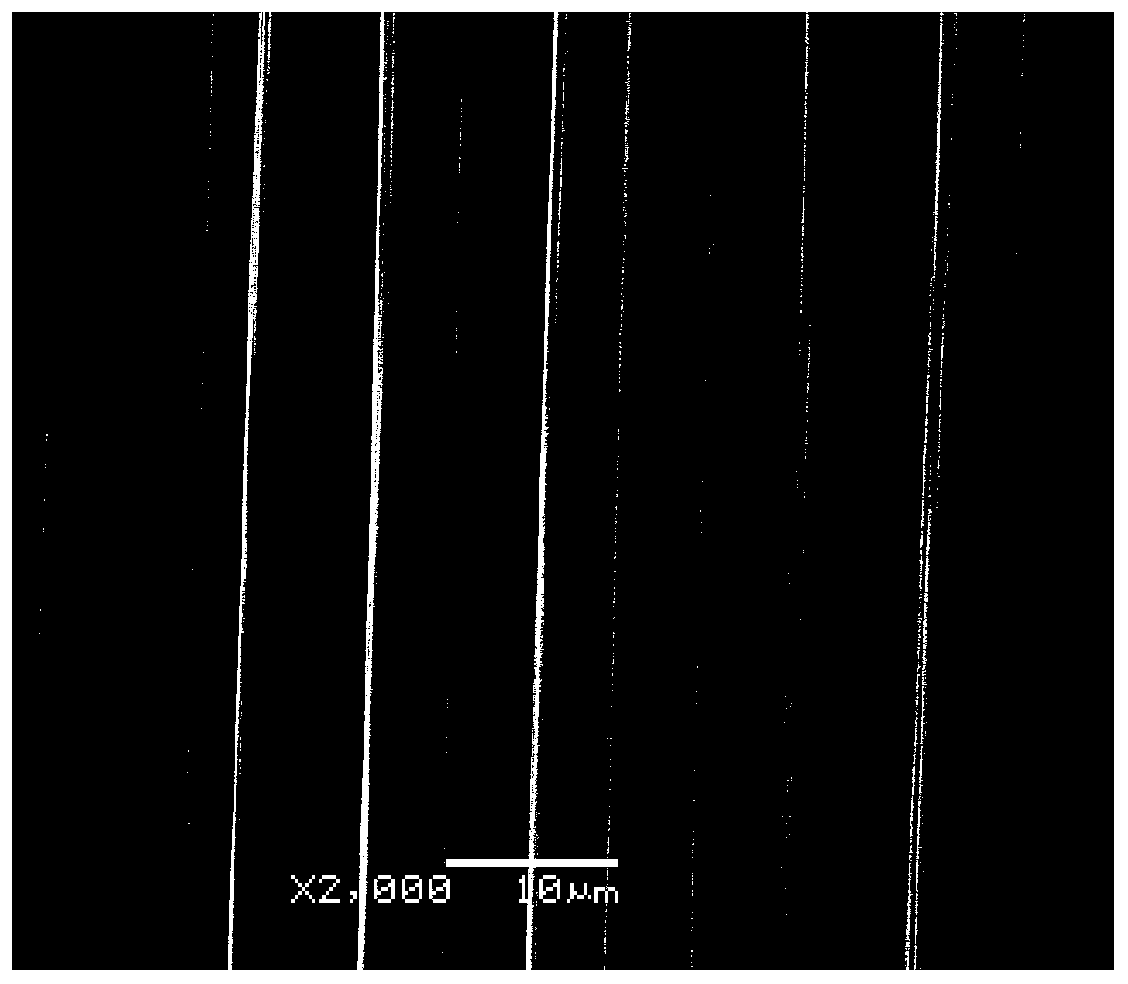

[0076] The raw silk of this embodiment selects monofilament diameter as 8 μ m, and density is 1.190g / cm 3 polyacrylonitrile fiber.

[0077] Pre-oxidation: make the polyacrylonitrile fibers enter the oxidation furnace, and carry out pre-oxidation under the oxygen atmosphere; wherein, the circulating air in the oxidation furnace is blown perpendicular to the running direction of the polyacrylonitrile fibers, and the wind speed is controlled at 0.6m / s, and the circulating air The water content is controlled at 10g m 3 / h. The initial temperature of pre-oxidation is 230°C, the end temperature is 280°C, and the temperature gradient is 13°C. During the pre-oxidation process, the pressure difference ΔP between the first position and the second position of the oxidation furnace is controlled at 15Pa; and the tension of the polyacrylonitrile fiber is controlled at 2000CN. The running speed of polyacrylonitrile fiber tow is 360m / h; the residence time of pre-oxidation is 30min. The p...

Embodiment 2

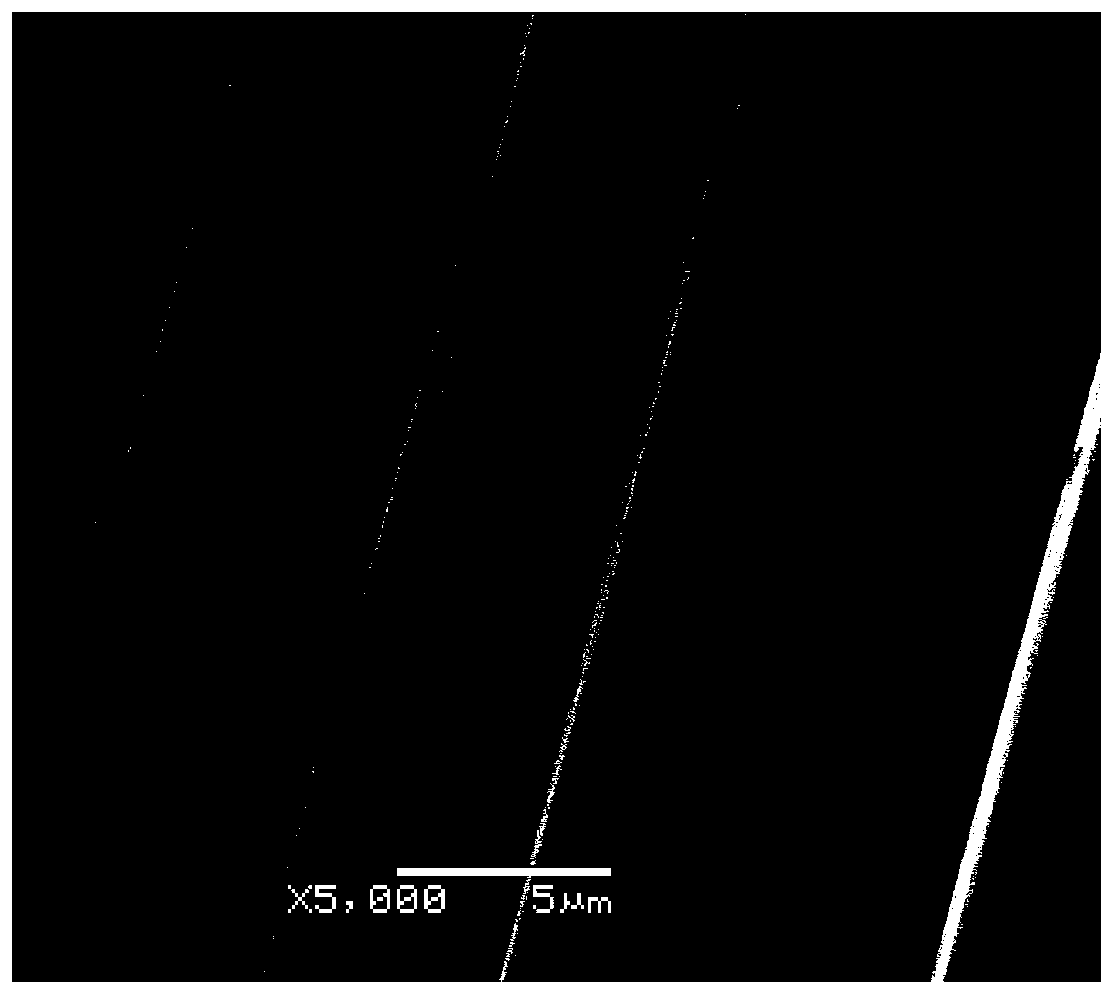

[0081] The raw silk of this embodiment selects monofilament diameter as 8 μ m, and density is 1.190g / cm 3 polyacrylonitrile fiber.

[0082] Pre-oxidation: make the polyacrylonitrile fibers enter the oxidation furnace, and carry out pre-oxidation under the oxygen atmosphere; wherein, the circulating air in the oxidation furnace is blown perpendicular to the running direction of the polyacrylonitrile fibers, and the wind speed is controlled at 0.6m / s, and the circulating air The water content is controlled at 12g m 3 / h. The initial temperature of pre-oxidation is 230°C, the end temperature is 280°C, and the temperature gradient is 13°C. During the pre-oxidation process, the direct pressure difference ΔP between the first position and the second position of the oxidation furnace is controlled at 15Pa; and the tension of the polyacrylonitrile fiber is controlled at 2000CN. The running speed of polyacrylonitrile fiber tow is 360m / h; the residence time of pre-oxidation is 30min....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com