Method for precisely determining ultraviolet absorbent in household product and pretreatment system

A household product, ultraviolet technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of different and large substrate differences, and achieve the effect of improving accuracy and efficient purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

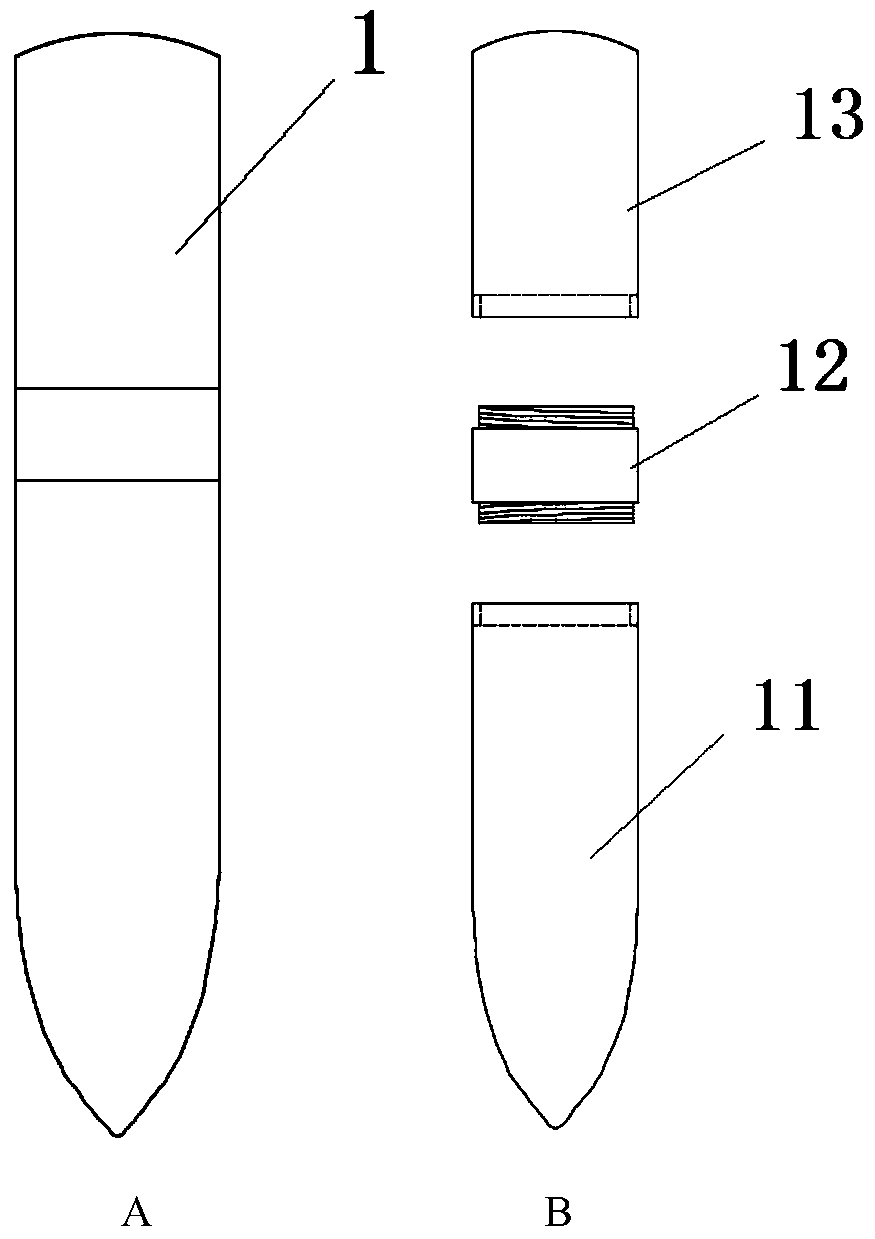

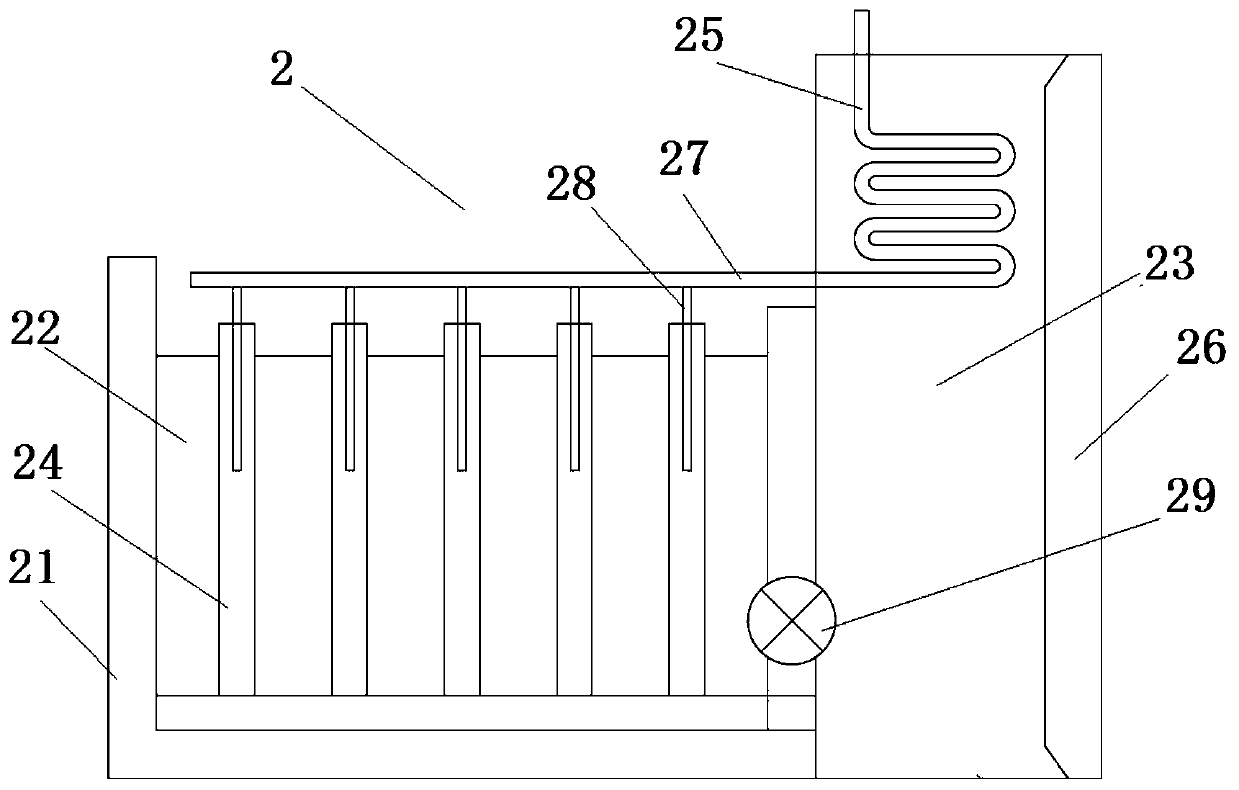

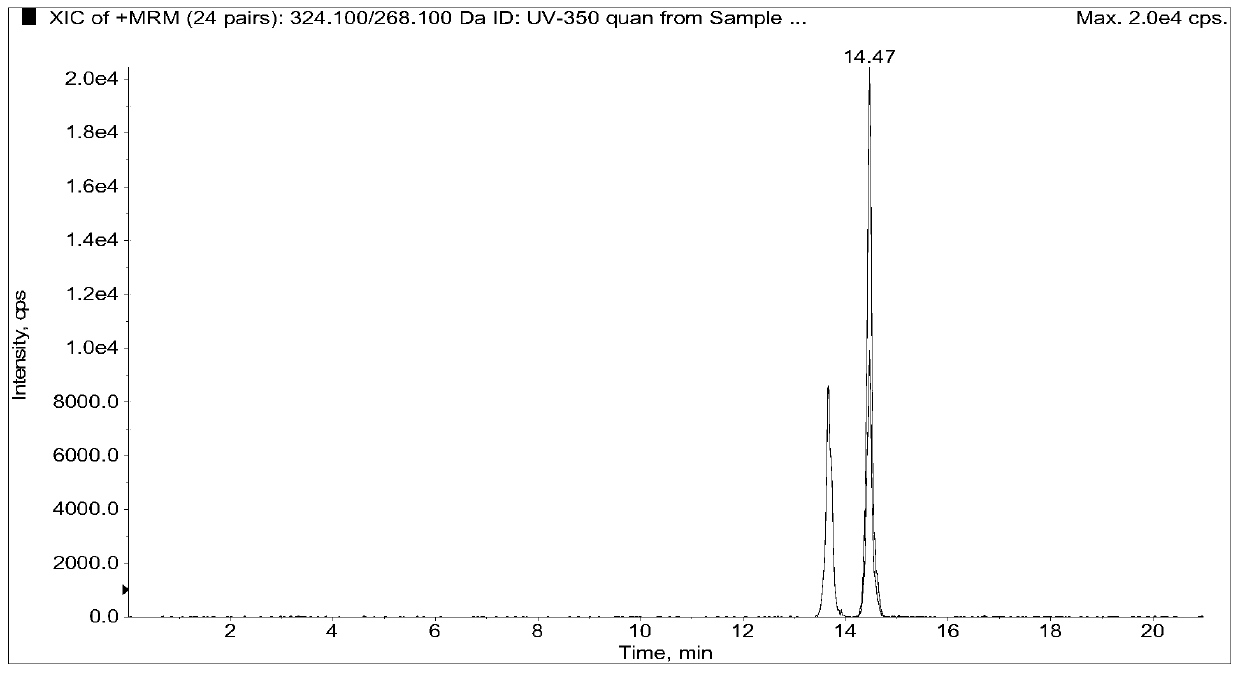

[0070] Such as Figure 1-2 As shown, the pretreatment system for precise determination of ultraviolet absorbers in household products provided by this embodiment includes an extraction and purification integrated test tube 1 and a high-efficiency concentration and enrichment device for concentrating the purified liquid in the extraction and purification integrated test tube 1 2 (that is, the high-efficiency concentration and enrichment device 2 is used to concentrate the purified liquid in the integrated extraction and purification test tube 1). The extraction and purification integrated test tube 1 includes a detachably connected extraction tube 11, a purification column 12 and a purification liquid collection tube 13 (before disassembly, it is shown in Figure A in Figure 1, and after disassembly, it is shown in Figure A). figure 1 Middle B figure), described efficient concentration enrichment device 2 comprises test tube rack 21, is located in the chamber 22 in test tube rac...

Embodiment 2

[0086] Instrument and equipment used in the present invention:

[0087] (1) AB 3200QTRAP liquid chromatography-tandem mass spectrometer;

[0088] (2) SIGMA high-speed refrigerated centrifuge 3-18K;

[0089] (3) IKA vortex mixer;

[0090] (4) Nitrogen blowing instrument;

[0091] (5) Electronic balance: Sensitivity 0.0001g, 0.00001g;

[0092] The reagent used in the present invention:

[0093] (1) Acetonitrile, methanol, ethanol, ethyl acetate, and ammonia water used in the sample extraction process were all analytically pure;

[0094] (2) The acetonitrile, methyl alcohol and formic acid used in the mobile phase are chromatographically pure;

[0095] (3) The water used in the detection process is ultrapure water.

[0096] The solvent-based coating is used as the test sample to illustrate:

[0097] 1. Preprocessing steps

[0098] 1.1 Extraction and purification

[0099] (1) Weigh 0.1 g (accurate to 0.0001 g) of the evenly stirred paint sample and place it in the extract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com