A kind of semi-regenerative reforming catalyst and preparation method thereof

A reforming catalyst and semi-regeneration technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of easy aggregation of metal components and weak adsorption of metal compounds, so as to achieve difficult aggregation, The effect of strong interaction and high aromatic selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

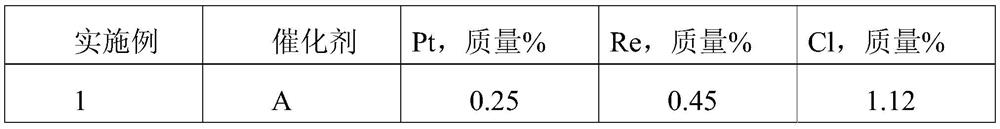

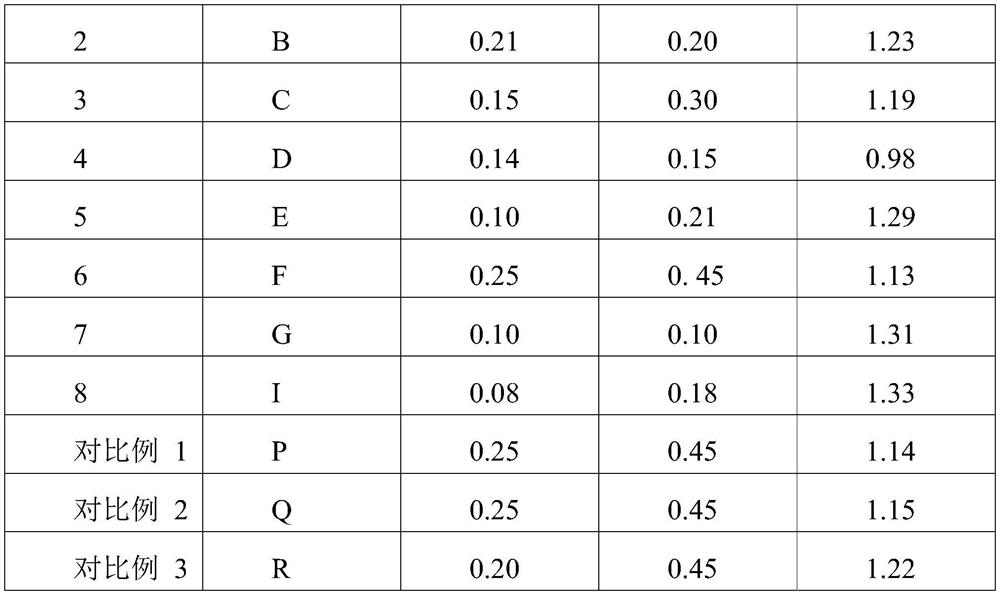

Examples

preparation example Construction

[0030] A kind of preparation method of semi-regenerated reforming catalyst, it is the preparation method of above-mentioned semi-regenerated reforming catalyst, comprises the steps:

[0031] Step 1, preparing a strip-shaped alumina carrier, the alumina being γ-alumina prepared from aluminum hydroxide obtained by hydrolysis of alkoxy aluminum;

[0032] Step 2, preparing an impregnating solution, which contains a platinum compound, a rhenium compound, a competitive adsorbent and an ammonium salt;

[0033] Step 3, impregnating the alumina carrier, and then drying;

[0034] Step 4, catalyst activation to obtain catalyst oxidation state precursor; and

[0035] Step 5, reducing and presulfiding the catalyst oxidation state precursor

[0036] In the preparation method of the semi-regenerative reforming catalyst of the present invention, in step 1, the carrier is preferably γ-alumina, more preferably γ-alumina prepared from high-purity aluminum hydroxide obtained by hydrolysis of al...

Embodiment 1

[0053] Get 300 grams of pseudo-boehmite powder (manufactured by Sasol Company), and 6 grams of fennel powder, and mix them evenly. Get 4 grams of nitric acid with a concentration of 65% by mass, 7 grams of acetic acid with a concentration of 36% by mass, and 210 grams of deionized water after mixing to form a peptizer, pour the peptizer into the mixed pseudoboehmite powder, and knead To be suitable for extruding, after extruding, dry at 60°C for 6 hours, dry at 120°C for 2 hours, and bake at 650°C for 4 hours in a flowing air atmosphere to obtain a strip-shaped γ-alumina carrier.

[0054] Prepare an impregnation solution containing chloroplatinic acid, perrhenic acid, hydrochloric acid, and tetramethylammonium bromide according to a predetermined amount, and the platinum content, rhenium content, HCl content and ammonium salt content in the impregnation solution are respectively 0.26% relative to the mass of dry alumina , 0.46%, 1.5% and 4.8%. Take the impregnating liquid to ...

Embodiment 2

[0056] Catalyst B was prepared according to the method of Example 1, except that the platinum content, rhenium content, HCl content and ammonium salt content in the impregnation solution were 0.22%, 0.21%, 2.1% and 2.5% relative to the mass of alumina on a dry basis, respectively. Specifically:

[0057] Get 300 grams of pseudo-boehmite powder (manufactured by Sasol Company), and 6 grams of fennel powder, and mix them evenly. Get 4 grams of nitric acid with a concentration of 65% by mass, 7 grams of acetic acid with a concentration of 36% by mass, and 210 grams of deionized water after mixing to form a peptizer, pour the peptizer into the mixed pseudoboehmite powder, and knead To be suitable for extruding, after extruding, dry at 60°C for 6 hours, dry at 120°C for 2 hours, and bake at 650°C for 4 hours in a flowing air atmosphere to obtain a strip-shaped γ-alumina carrier.

[0058] Prepare an impregnation solution containing chloroplatinic acid, perrhenic acid, hydrochloric ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com