Halogen bismuth oxide/titanium carbide photocatalysis composite material and preparing method thereof

A composite material, bismuth oxyhalide technology, applied in the field of photocatalytic materials, to achieve excellent photocatalytic activity, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Preparation of photocatalyst

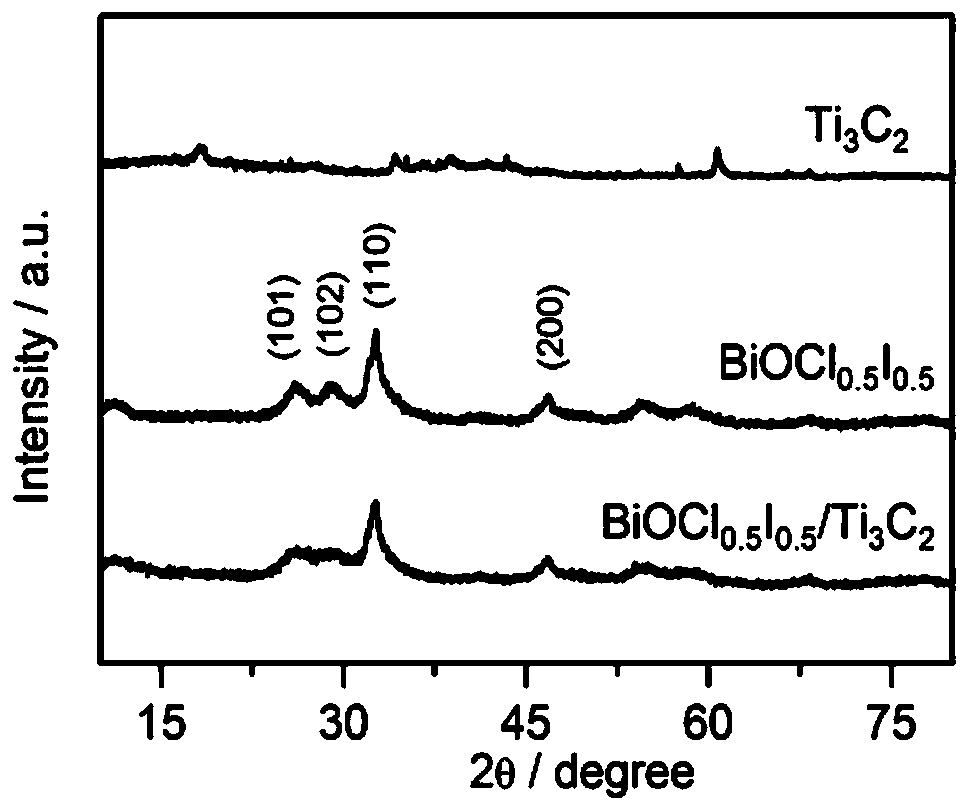

[0025] 1g Ti 3 AlC 2 Slowly added to 20mL of 40% HF solution, stirred at a constant temperature of 60°C for 48 hours, washed and dried to obtain Ti 3 C 2 Material. Subsequently, 1 g of the acid-etched Ti 3 C 2 material, slowly added to 5ml dimethyl sulfoxide solution, ultrasonically dispersed for 24 hours, left to stand, washed, centrifuged, and dried to obtain ultra-thin two-dimensional Ti 3 C 2 Material.

[0026] 4mmol Bi(NO 3 )·5H 2 O with 6.12 mg Ti 3 C 2 Add it into 40mL of ethylene glycol, and ultrasonically disperse for 15 minutes to obtain A solution. Add 2mmol KI and 2mmol KCl into 40mL ethylene glycol, and ultrasonically disperse for 15 minutes to obtain B solution. Subsequently, solution B was added dropwise to solution A, stirred for 60 minutes to form a uniformly dispersed mixed solution, transferred to an autoclave, and reacted at a constant temperature of 160°C for 24 hours, washed and dried to obtain BiOCl ...

Embodiment 2

[0034] 1) Preparation of photocatalyst

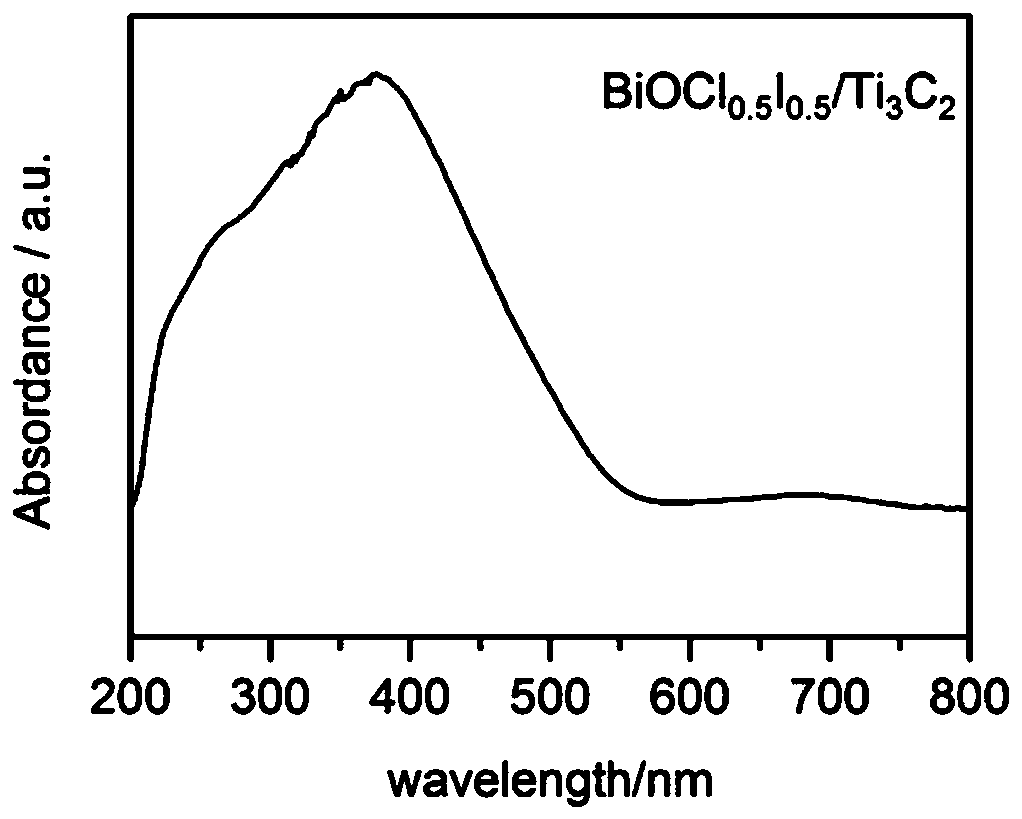

[0035] 2mmol Bi(NO 3 )·5H 2 O with 3.06 mg Ti 3 C 2 Add it into 40mL of ethylene glycol, and ultrasonically disperse for 15 minutes to obtain A solution. 0.5mmol KI and 0.5mmol KCl were added in 40mL ethylene glycol, and ultrasonically dispersed for 15 minutes to obtain B solution. Subsequently, solution B was added dropwise to solution A, stirred for 60 minutes to form a uniformly dispersed mixed solution, transferred to an autoclave, and reacted at a constant temperature of 180°C for 24 hours, washed and dried to obtain BiOCl 0.5 I 0.5 / Ti 3 C 2 composite material. In the absence of Ti 3 C 2 Under the condition of pure BiOCl 0.5 I 0.5 was synthesized in the same way.

[0036] 2) Photocatalysis experiment

[0037] The prepared above-mentioned photocatalyst (1g / L) is put into the Cr(VI) solution (50ml) that concentration is 60ppm, under magnetic stirring condition, after dark reaction 30 minutes, turn on xenon lamp light s...

Embodiment 3

[0040] 4mmol Bi(NO 3 )·5H 2 O with 6.12 mg Ti 3 C 2 Add it into 40mL of ethylene glycol, and ultrasonically disperse for 15 minutes to obtain A solution. 0.8mmol KI and 0.2mmol KCl were added in 40mL ethylene glycol, and ultrasonically dispersed for 15 minutes to obtain B solution. Subsequently, solution B was added dropwise to solution A, stirred for 60 minutes to form a uniformly dispersed mixed solution, transferred to an autoclave, and reacted at a constant temperature of 150°C for 24 hours, washed and dried to obtain BiOCl 0.2 I 0.8 / Ti 3 C 2 composite material.

[0041] Adopt the test method described in embodiment 2 to test the photocatalyst that this example makes under visible light irradiation to the degradative activity of antibiotic, reach 86% to the degradation rate of antibiotic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com