Method for preparing imitation ceramic leak-proof glass bottle body and imitation ceramic leak-proof glass bottle

A technology of glass bottles and imitation ceramics, which is applied in the field of preparing imitation ceramic leak-proof glass bottles and imitation ceramic leak-proof glass bottles, which can solve the problems of insufficient safety, high production costs, high material costs, etc., and prevent light from entering the bottle , protection from damage, good effect of anti-leakage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

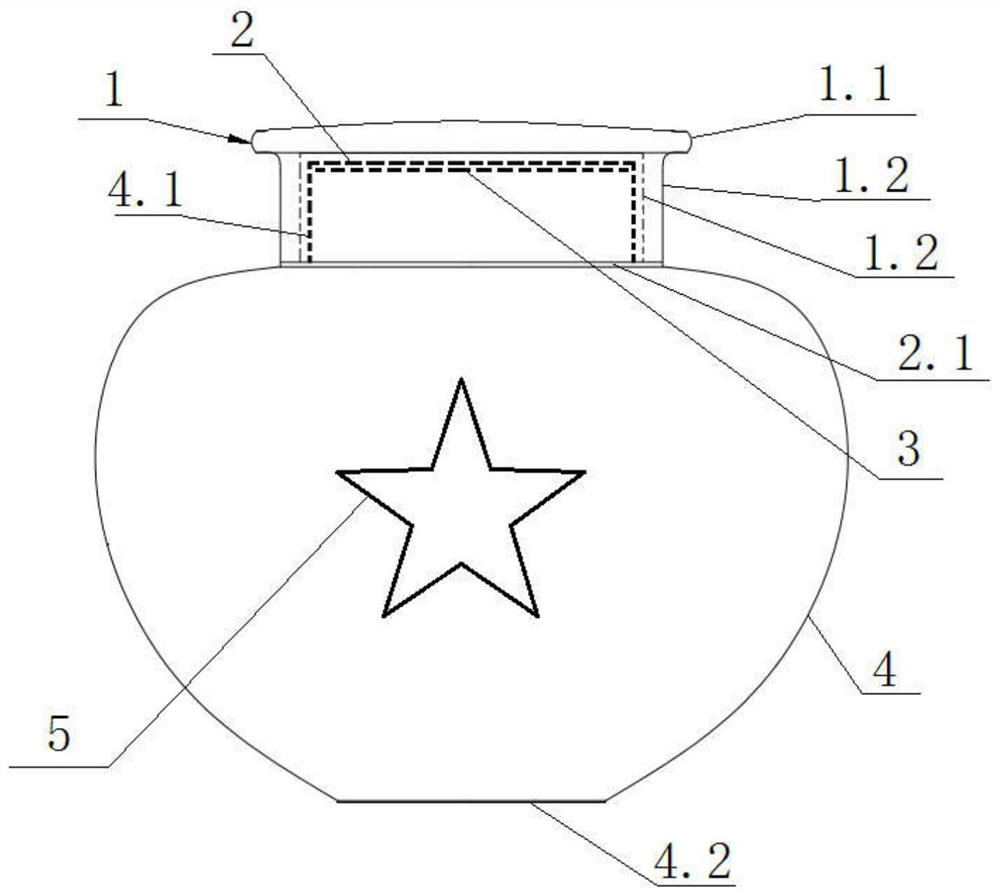

[0044] The implementation of the present invention will be described in detail below with reference to the accompanying drawings, but they do not constitute a limitation of the present invention, but are merely examples. At the same time, the advantages of the present invention are made clearer and easier to understand by the description.

[0045] A method for preparing an imitation ceramic leak-proof glass bottle body comprises the following steps:

[0046] Step 1: Preprocessing of raw materials,

[0047] The raw materials for the imitation ceramic leak-proof glass bottle body are selected and the dosage is determined. The selected imitation ceramic leak-proof glass bottle body raw materials include broken glass, soda ash, quartz sand, feldspar powder, sodium nitrate, fluorite, sodium fluorosilicate, calcite and titanium dioxide ; Weigh a certain weight portion of the raw materials of the imitation ceramic leak-proof glass bottle body respectively, and pulverize and dry the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com