High-temperature-ablation-resistant fireproof silicone sealant and preparation method thereof

A technology of silicone sealant and high temperature resistance, applied in the field of sealant, can solve the problems of loose structure of ablation products, poor fireproof effect, weak displacement resistance, etc., achieve good mechanical properties, good fireproof and flame retardant effect, satisfy The effect of fire resistance class requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

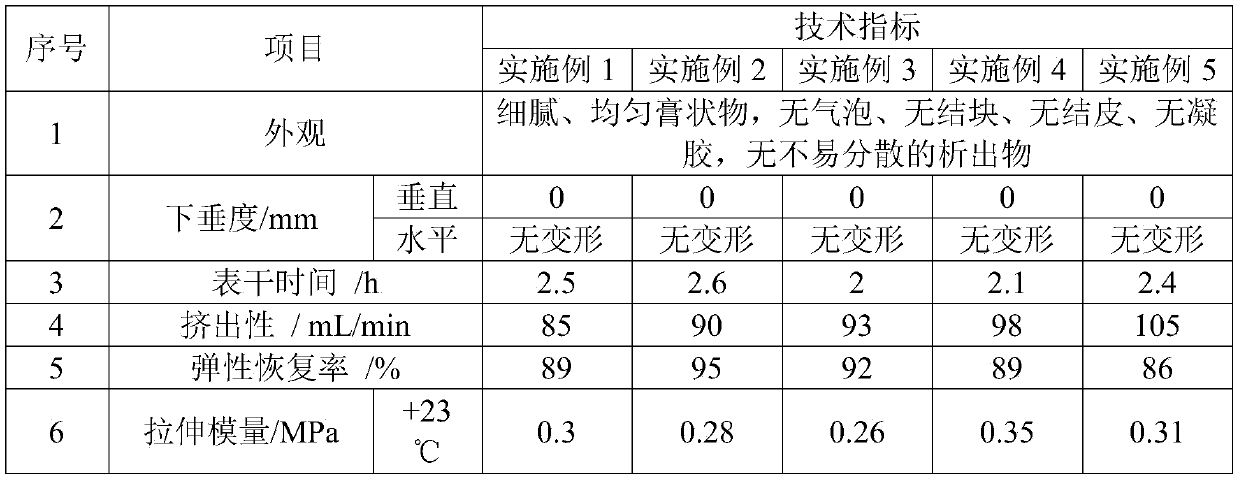

Examples

Embodiment 1~5

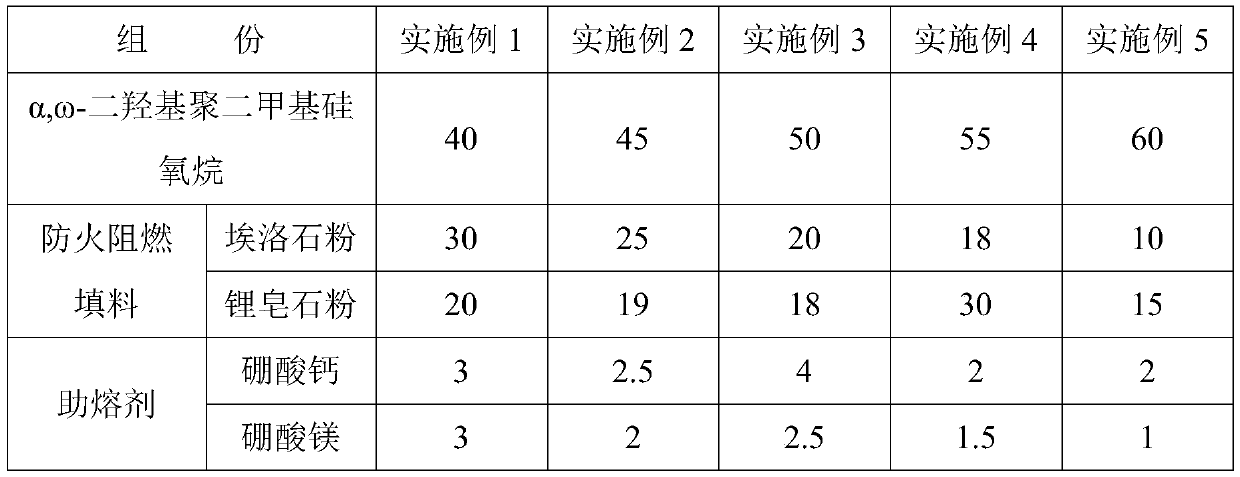

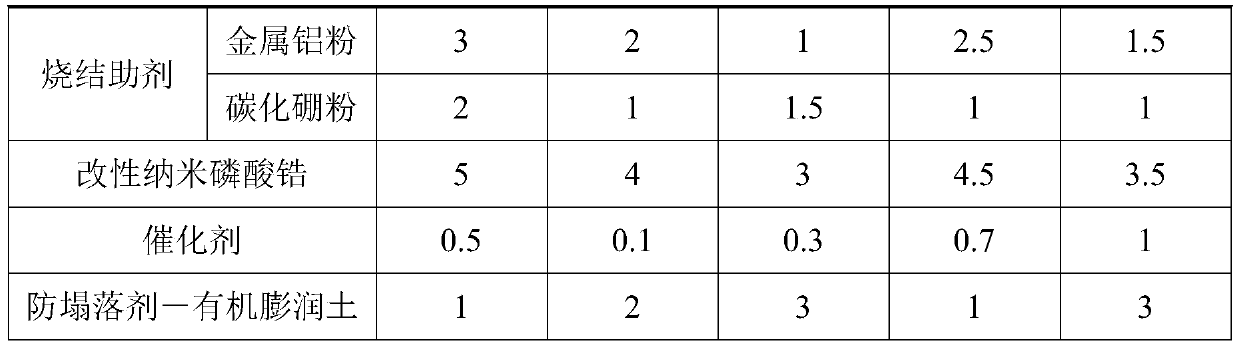

[0027] Examples 1-5: Refer to Table 1 for the components and parts by mass of the high-temperature ablation-resistant fireproof silicone sealant described in the examples. The raw materials used are as follows:

[0028] α,ω-Dihydroxypolydimethylsiloxane, purchased from the market, was purchased from Dow Corning Corporation.

[0029] The fire-resistant and flame-retardant fillers were halloysite powder and hectorite powder, which were purchased from the market and purchased from Shijiazhuang Guangning Mineral Products Company.

[0030] The fluxes are calcium borate and magnesium borate, which are purchased from the market and purchased from Zhengzhou Wanchuang Chemical Industry.

[0031] The sintering aid is self-made, and its raw materials are metal aluminum powder and boron carbide powder, which are purchased from the market and purchased from Changzhou Yongjiang Grinding Wheel Company.

[0032] The high-efficiency flame retardant is modified nano-zirconium phosphate, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com