Method for preparing liquid fuel by catalyzing lignin with Ni-ReOx/Al2O3

A technology for liquid fuel and lignin, which is used in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oil, etc., can solve problems such as difficult and efficient degradation and utilization, and achieve the effects of high yield, mild reaction conditions, and reduced catalytic costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 200 mg lignin model compound phenoxyethylbenzene, 20 mg catalyst Ni-ReO x / Al 2 o 3 (1wt%Ni, 2wt%Re), 30ml of water was added to a 100ml reactor, and hydrogen gas was introduced to replace the gas three times, then filled with hydrogen to 2.0MPa, heated to 180°C, and reacted for 3 hours. After the reaction, cool to room temperature, add ethyl acetate for extraction, and obtain the supernatant of the organic phase for chromatographic analysis. The conversion rate is 99.9%, the yield of ethylcyclohexane is 95.7%, and the yield of cyclohexane is 85.6%.

Embodiment 2-3

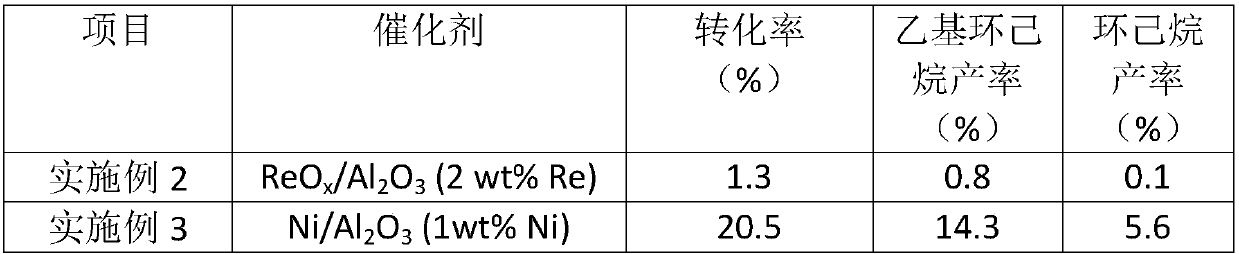

[0020] Other processing conditions and experimental steps are the same as in Example 1, but using different catalysts, the results are shown in Table 1. Table 1. Experimental results of the lignin model compound phenoxyethylbenzene catalyzed by different catalysts

[0021]

[0022] Compared with pure Ni / Al 2 o 3 and ReO x / Al 2 o 3 When catalytically converting lignin model compounds, the substrate conversion rate, ethylcyclohexane and cyclohexane yields are all low, only when Ni and ReO x Simultaneous loading of Ni-ReOx / Al 2 o 3 , higher yields of ethylcyclohexane and cyclohexane were obtained, indicating that Ni and ReOx have a synergistic catalytic effect.

Embodiment 4-8

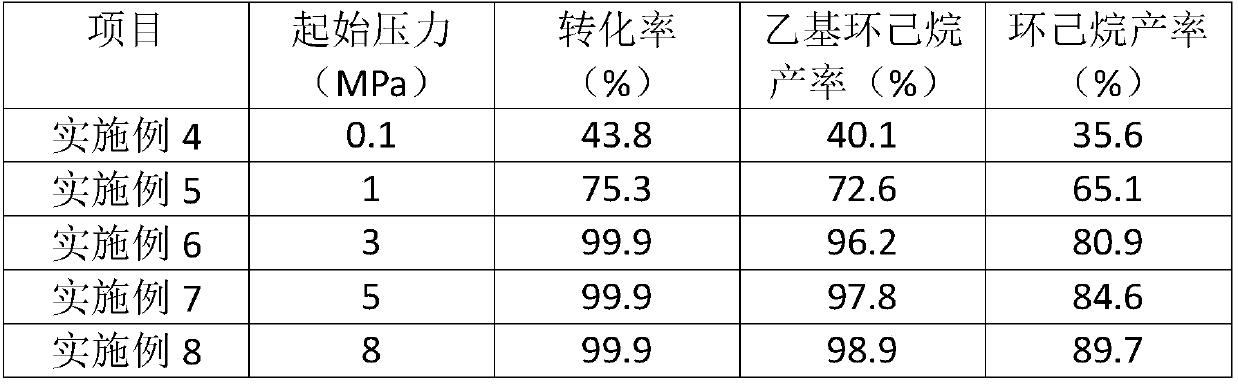

[0024] Other process conditions and experimental steps are the same as in Example 1, but using different initial pressures, the results are shown in Table 2.

[0025] Table 2. At different initial pressures, Ni-ReO x / Al 2 o 3 (1wt%Ni, 2wt%Re) catalytic lignin model compound phenoxyethylbenzene experimental results

[0026]

[0027] As shown in Table 2, as the initial pressure increased, the yields of ethylcyclohexane and cyclohexane increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com