A kind of spherical hard carbon material and preparation method thereof

A hard carbon and spherical technology, which is applied in the field of spherical hard carbon materials and their preparation, can solve problems affecting the performance of materials, affecting the low-temperature performance of start-stop power supplies, high-rate charge and discharge capabilities, and large-rate performance deviations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

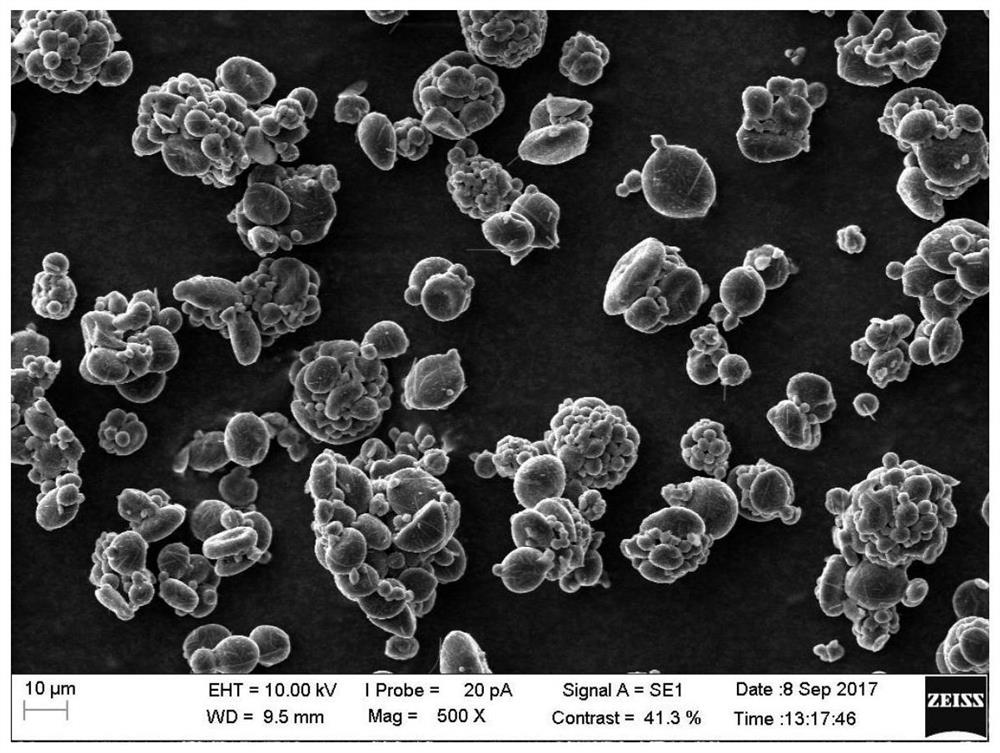

Image

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of spherical hard carbon material, comprises the following steps:

[0025] (1) mixing the phenolic resin with an organic solvent to obtain a phenolic resin solution;

[0026] (2) mixing the phenolic resin solution obtained in the step (1) with sulfonated polystyrene microspheres and aminosilane, and successively undergoing reflux reaction and elution to obtain a precursor material;

[0027] (3) mixing the precursor material obtained in the step (2) with the lithium salt to obtain a composite material;

[0028] (4) The composite material obtained in the step (3) is subjected to chemical vapor deposition to obtain a spherical hard carbon material.

[0029] In the invention, the phenolic resin is mixed with an organic solvent to obtain a phenolic resin solution. In the present invention, the organic solvent preferably includes N-methylpyrrolidone, carbon tetrachloride, toluene, diphenylamine, N,N-dimethylformamide or n-...

Embodiment 1

[0049] (1) Add 61g of phenolic resin to 1000mL of N-methylpyrrolidone and be prepared with a concentration of phenolic resin solution of 0.5mol / L;

[0050] (2) After adding 1.83g sulfonated polystyrene microspheres in the phenolic resin solution that described step (1) obtains and stir, add 1.83g gamma-aminopropyltrimethoxysilane again, and transfer in the Erlenmeyer flask, And reflux reaction at 70°C for 12h; filter the reflux reaction product, soak the filtered solid in tetrahydrofuran solution for 24h to elute; after the elution is completed, filter the eluted product, dry the filtered solid to obtain a precursor Material;

[0051] (3) Add 5g of lithium acetate to 100mL N-methylpyrrolidone to prepare a lithium salt solution with a mass concentration of 5%; then add 100g of the precursor material obtained in step (2) to the lithium salt solution and stir evenly Finally, filter and dry to obtain the composite material;

[0052] (4) The composite material obtained in the ste...

Embodiment 2

[0054] (1) 12.2g phenolic resin is added in 1000mL carbon tetrachloride and is mixed with the phenolic resin solution that molar concentration is 0.1mol / L;

[0055] (2) After adding 0.122g sulfonated polystyrene microspheres in the phenolic resin solution obtained in the step (1) and stirring evenly, then add 0.122g 3-aminopropyltriethoxysilane, and transfer to the Erlenmeyer flask and reflux reaction at 30°C for 24h; filter the reflux reaction product, soak the filtered solid in tetrahydrofuran solution for 6h to elute; after the elution is completed, filter the eluted product, and dry the filtered solid to obtain Precursor material;

[0056] (3) Add 1g butyllithium to 1000mL carbon tetrachloride to prepare a lithium salt solution with a mass concentration of 1%; then add 100g of the precursor material obtained in step (2) to the lithium salt solution and stir evenly Finally, filter and dry to obtain the composite material;

[0057] (4) The composite material was subjected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com