Foam collecting and crushing device of wet flue gas desulfurization system of coal-fired power station

A wet flue gas desulfurization, coal-fired power station technology, applied in foam dispersion/prevention, gas treatment, separation methods, etc., can solve the problems of changing the quality of the slurry, affecting the absorption of sulfur dioxide, reducing the desulfurization efficiency, etc., to enhance the removal effect, The effect of increasing the storage capacity and simplifying the structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

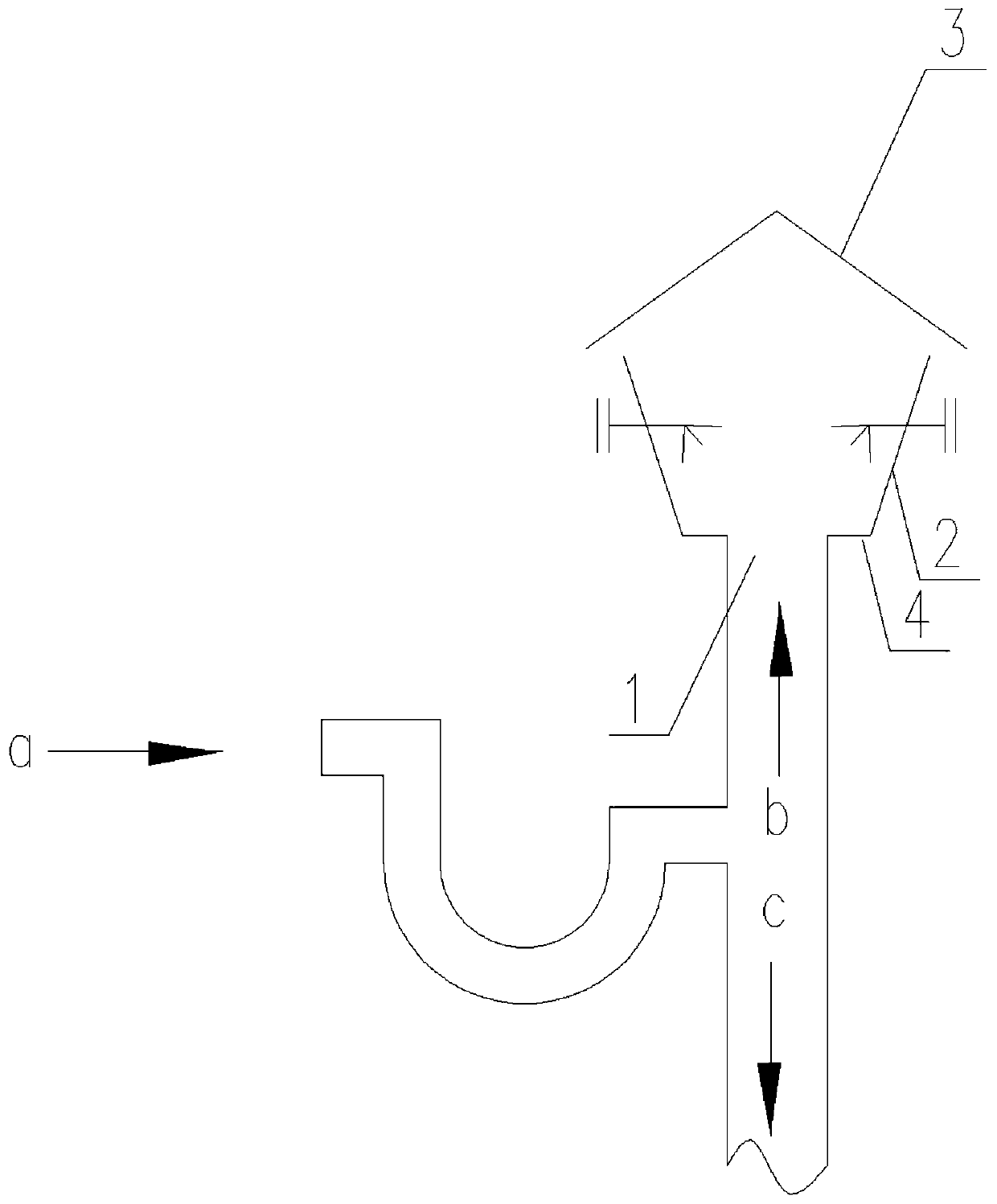

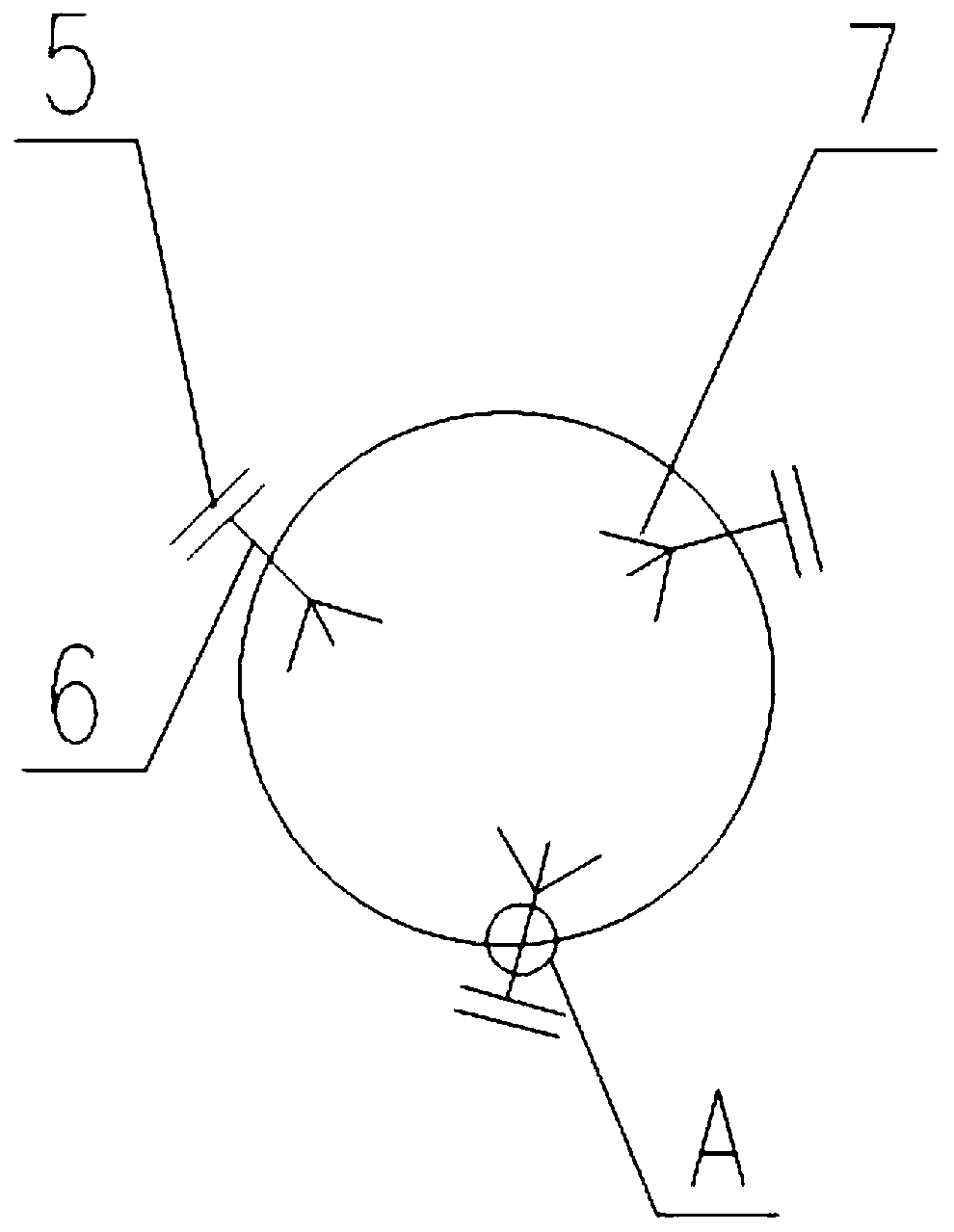

[0030] Such as figure 1 , the coal-fired power plant wet flue gas desulfurization foam collection and spraying device provided by the present invention includes an overflow pipe 1, a foam breaking cover 2, an exhaust cap 3, a liquid level sensor 4, a connecting flange 5, a nozzle connecting pipe 6 and nozzle7. The overflow pipe 1 communicates with the absorption tower of the coal-fired power station, the foam crushing cover 2 communicates with the upper end outlet of the overflow pipe 1, the nozzle 7 is evenly arranged on the inner wall of the foam crushing cover 2, and the exhaust cap 3 is arranged on the foam crushing cover 2, the liquid level sensor 4 is located at the bottom of the foam breaking cover 2.

[0031] The nozzle 7 of this embodiment is connected to the flushing pipe (not shown in the figure) sequentially through the nozzle connecting pipe 6 and the connecting flange 5 .

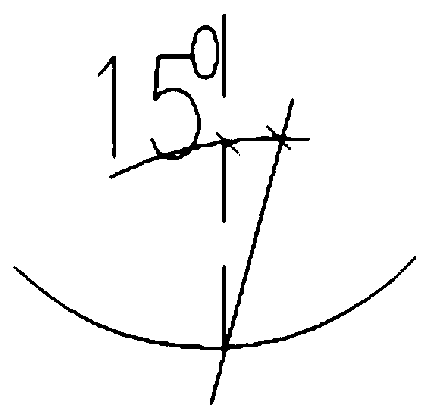

[0032] The included angle between the axial direction of the nozzle 7 and the radial dir...

Embodiment 2

[0042] This embodiment is applied in a 600MW unit wet desulfurization device of a coal-fired power station, and the specific working parameters are as follows (the rest of the components and equipment are set in the same way as in Embodiment 1):

[0043]

[0044] There are 4 nozzles in this embodiment, and the coverage rate of the nozzles in the foam breaking cover is 200%.

[0045] The foam breaking cover has an inverted cone structure, the top surface is a circle of Φ800, and the bottom surface is a circle of Φ400. The included angle between the inner wall of the foam breaking hood and the center line of the foam breaking hood is 15°.

[0046] The foam breaking cover is made of 904L stainless steel.

[0047] The inner wall of the foam breaking cover of the present embodiment is equipped with thorns for breaking the foam when spraying. The length of the main branches of the thorns is 5 cm, and the length of the twigs is 1 cm. The burr is made of 904L stainless steel.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com