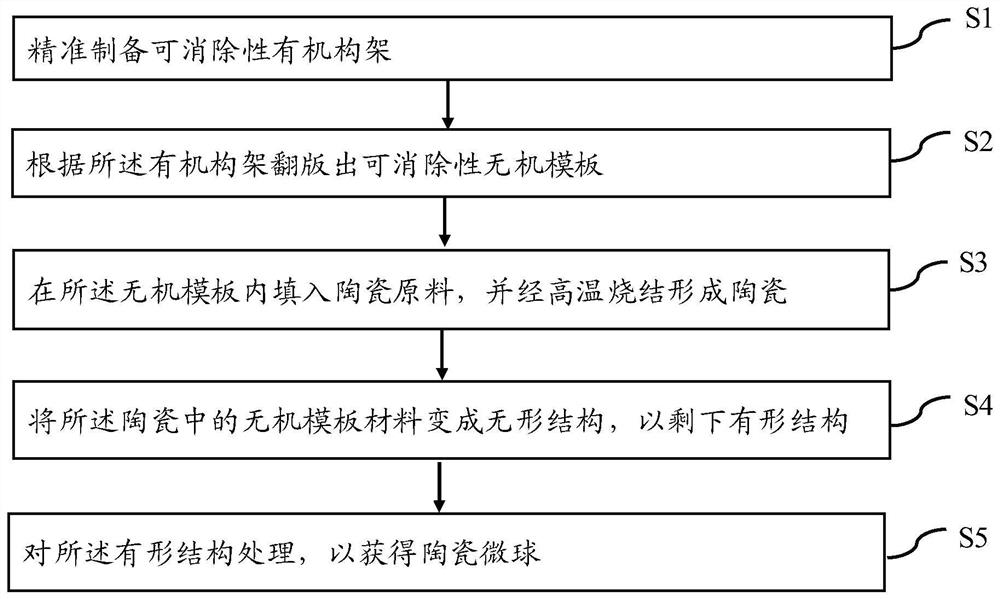

Method for preparing ceramic microspheres by template method

A technology of ceramic microspheres and template method, which is applied in the field of ceramic materials, can solve the problems of difficulty in obtaining porous ceramic microspheres with large pore size and high connectivity porosity, long solidification time, and easy bursting of bubbles, so as to achieve consistent appearance and pollution The effect of reducing chance and stabilizing chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

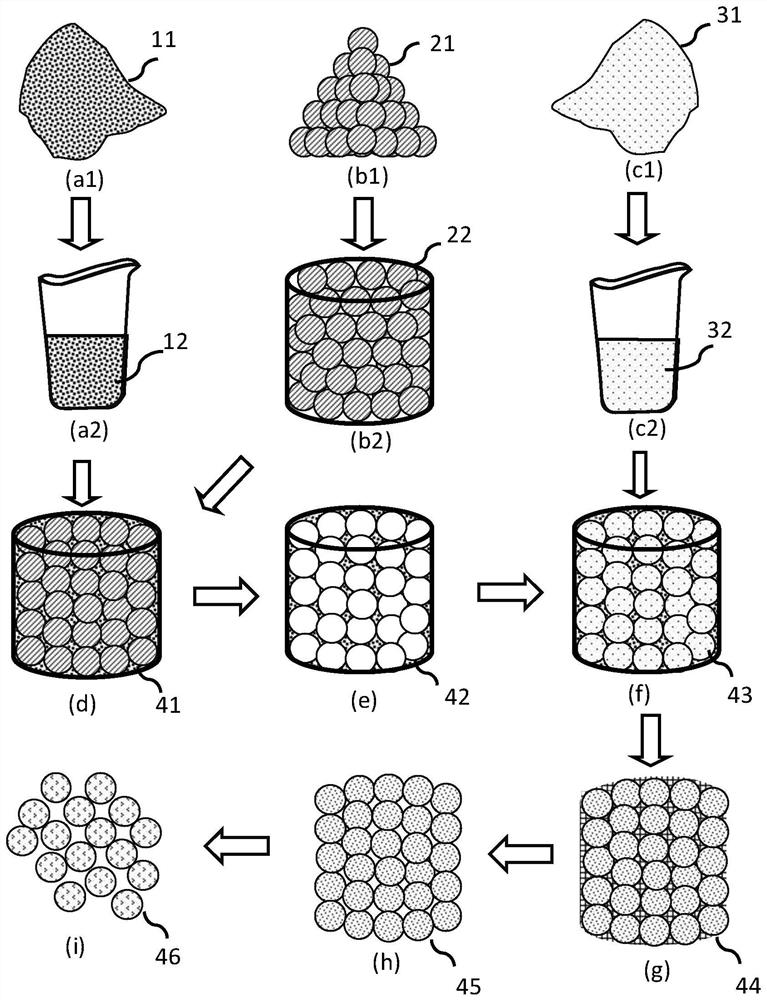

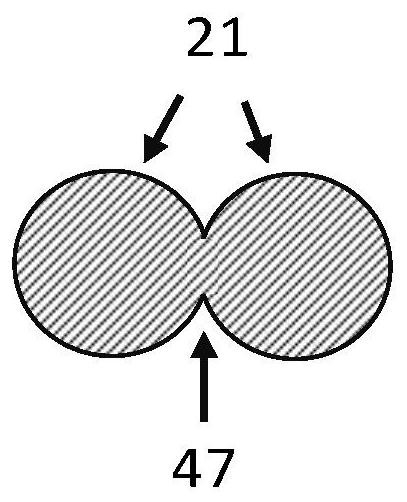

[0064] Step S1, adding polymethyl methacrylate (PMMA) organic microspheres (φ600μm~800μm) into a stainless steel cylindrical mold (φ100cm×100cm), after shaking and filling, heating the whole to 220°C for 6 hours , so that contact bonding occurs between the organic microspheres (such as image 3 shown), then cooled to form a removable organic framework;

[0065]Step S2, ball milling and mixing the calcium carbonate ceramic powder, dispersant, defoamer and solvent to prepare a calcium carbonate ceramic slurry with good fluidity; pour the calcium carbonate ceramic slurry into the organic frame, and dry to form Calcium carbonate ceramic body; debinding the calcium carbonate ceramic body at 350°C for 8 hours to obtain a removable inorganic template;

[0066] Step S3, ball milling and mixing the tricalcium phosphate ceramic powder, dispersant, defoamer and solvent to prepare a tricalcium phosphate ceramic raw material with good fluidity; pouring the tricalcium phosphate ceramic raw...

no. 2 example

[0070] Step S1, add polymethyl methacrylate (PMMA) organic microspheres (φ600μm~800μm) into a stainless steel cylindrical mold (φ100cm×100cm), after shaking and filling, add acetone at room temperature for 2 minutes, and use pure Washing with water terminates the dissolution of acetone on the surface of organic microspheres, and bonds to form a removable organic framework;

[0071] Step S2, ball milling and mixing the calcium carbonate ceramic powder, dispersant, defoamer and solvent to prepare a calcium carbonate ceramic slurry with good fluidity; pour the calcium carbonate ceramic slurry into the organic frame, and dry to form Calcium carbonate ceramic body; debinding the calcium carbonate ceramic body at 350°C for 8 hours to obtain a removable inorganic template;

[0072] In step S3, tricalcium phosphate ceramic powder, hydroxyapatite ceramic powder, dispersant, defoamer and solvent are mixed by ball milling to prepare tricalcium phosphate and hydroxyapatite dual-phase cera...

no. 3 example

[0076] Step S1, adding polymethyl methacrylate (PMMA) organic microspheres (φ600μm~800μm) into a stainless steel cylindrical mold (φ100cm×100cm), after shaking and filling, adding a binder at room temperature for 35 minutes, Rinse off the remaining adhesive with pure water to terminate the bonding to form a removable organic framework;

[0077] Step S2, ball milling and mixing the calcium carbonate ceramic powder, dispersant, defoamer and solvent to prepare a calcium carbonate ceramic slurry with good fluidity; pour the calcium carbonate ceramic slurry into the organic frame, and dry Forming a calcium carbonate ceramic body; the calcium carbonate ceramic body is subjected to debinding at 350°C for 8 hours to obtain a removable inorganic template;

[0078] Step S3, ball milling and mixing hydroxyapatite, PMMA pore-forming agent particles (φ1 μm-5 μm), dispersant, defoamer and solvent to prepare a hydroxyapatite ceramic raw material with good fluidity; the hydroxyapatite Limest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com