Metal organic complex of divalent zinc ions and preparation method and application of metal organic complex

A metal-organic and complex technology, which is applied in zinc-organic compounds, organic compounds/hydrides/coordination complex catalysts, organic chemistry, etc., can solve the problems of catalyst recycling difficulties, environmental pollution, etc., and achieve easy recycling and reduced Cost, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

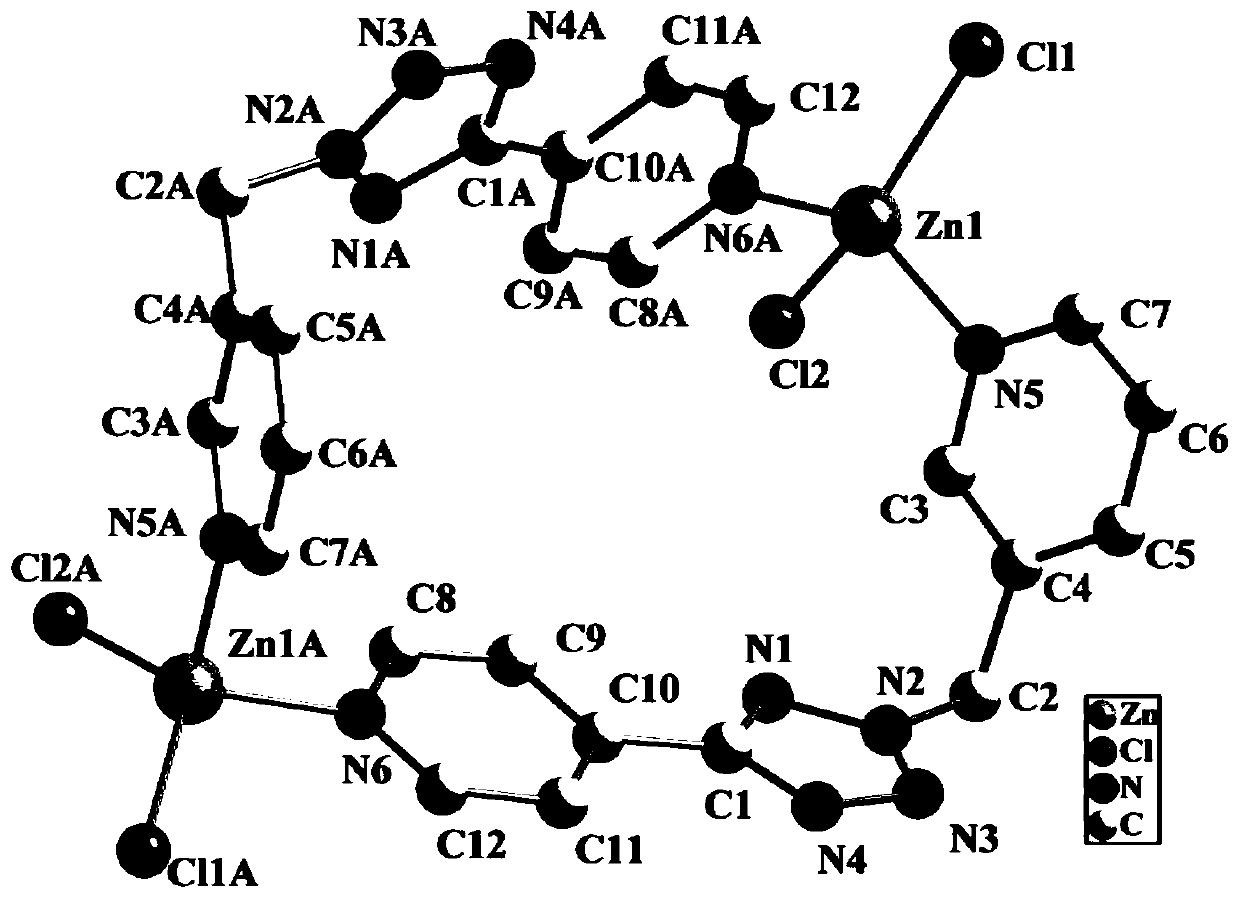

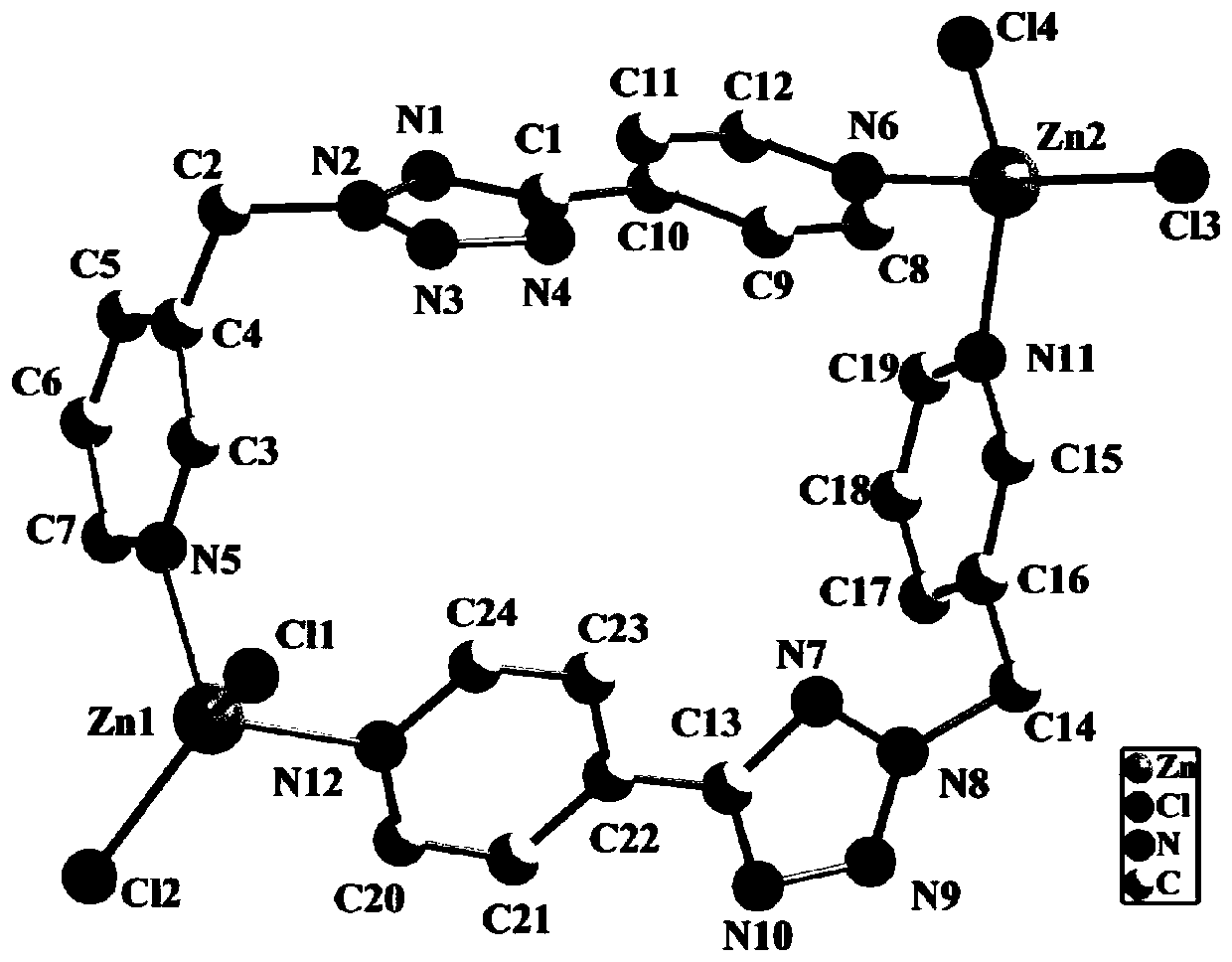

Embodiment 1

[0061] The preparation of organic ligand L, the specific preparation steps are as follows:

[0062] (1) In a 50ml single-necked round bottom flask, add 4-cyanopyridine (2.08g, 20mmol) and sodium azide (1.56g, 24mmol) and then add anhydrous ammonium chloride (1.28g, 24mmol), add N , N-dimethylformamide (ie DMF) 20ml, heating and stirring at 120°C for 48h, followed by TLC. After the reaction is completed, cool it down, then pour it into a beaker filled with a large amount of deionized water, adjust the pH to pH 5-6 by adding dilute hydrochloric acid dropwise with a dropper, heat slowly with an electric heating mantle, and evaporate to dryness to obtain a light pink intermediate. After drying at room temperature and weighing, 4.59 g of a light pink intermediate was obtained, with a yield of 61%.

[0063] (2)N 2 Under protection, intermediate A (3.53g, 24mmol), 3-chloromethylpyridine (4.14g, 25.2mmol), anhydrous potassium carbonate (16.56g, 120mmol) were added to a 250ml single-...

Embodiment 2

[0066] The preparation of organic ligand L, the specific preparation steps are as follows:

[0067] (1) In a 50ml single-necked round bottom flask, add 4-cyanopyridine (2.08g, 20mmol) and sodium azide (1.3g, 20mmol) and then add anhydrous ammonium chloride (1.07g, 20mmol), add N , N-dimethylformamide (ie DMF) 20ml, heating and stirring at 110°C for 44h, followed by TLC. After the reaction is completed, cool it down, then pour it into a beaker filled with a large amount of deionized water, adjust the pH to pH 5-6 by adding dilute hydrochloric acid dropwise with a dropper, heat slowly with an electric heating mantle, and evaporate to dryness to obtain a light pink intermediate. Dry at room temperature and weigh to obtain 4.32 g of a light pink intermediate with a yield of 58%.

[0068] (2)N 2 Under protection, intermediate A (3.53g, 24mmol), 3-chloromethylpyridine (3.94g, 24mmol), anhydrous potassium carbonate (13.248g, 96mmol), potassium iodide (1.56g ,9.4mmol), then add 60....

Embodiment 3

[0070] The preparation of organic ligand L, the specific preparation steps are as follows:

[0071] (1) In a 50ml single-necked round bottom flask, add 4-cyanopyridine (2.08g, 20mmol) and sodium azide (1.95g, 30mmol) and then add anhydrous ammonium chloride (1.6g, 30mmol), add N , N-dimethylformamide (ie DMF) 20ml, heating and stirring at 130°C for 52h, followed by TLC. After the reaction is completed, cool it down, then pour it into a beaker filled with a large amount of deionized water, adjust the pH to pH 5-6 by adding dilute hydrochloric acid dropwise with a dropper, heat slowly with an electric heating mantle, and evaporate to dryness to obtain a light pink intermediate. After drying at room temperature and weighing, 4.7 g of a light pink intermediate was obtained, with a yield of 60%.

[0072] (2)N 2 Under protection, intermediate A (3.53g, 24mmol), 3-chloromethylpyridine (5.91g, 36mmol), anhydrous potassium carbonate (19.872g, 144mmol), potassium iodide (1.56g ,9.4mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com