High-refractive index microsphere Mie scattering based schemochrome coating

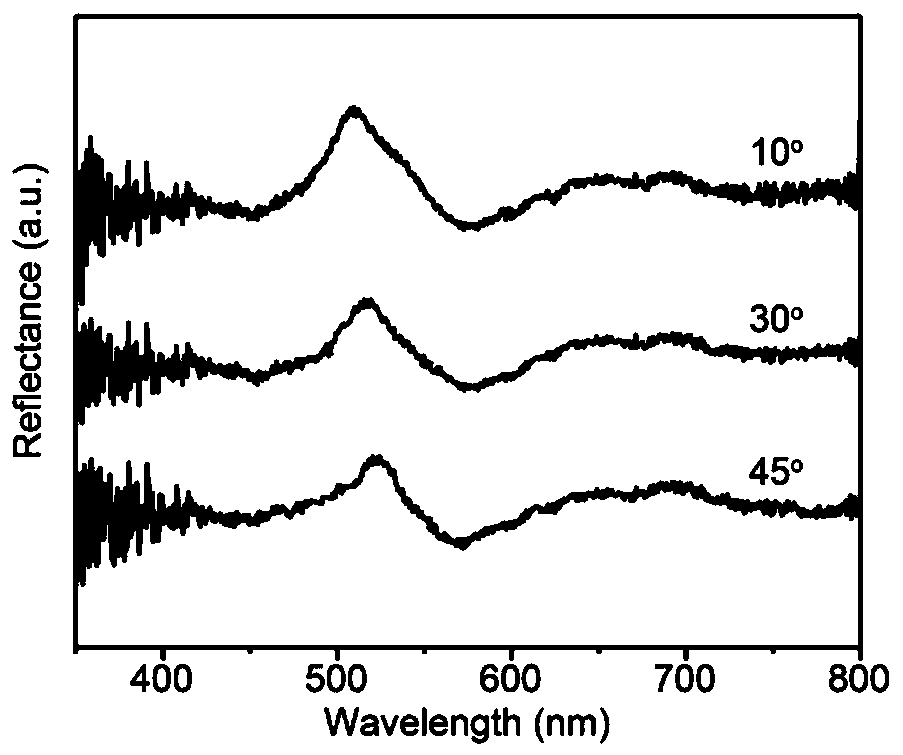

A high-refractive index, structural color technology, applied in the field of structural color, can solve the problem of dull color and achieve bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

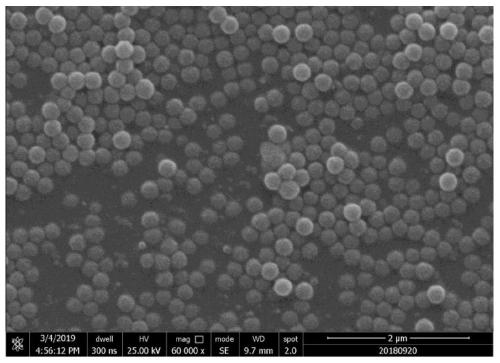

[0027] Preparation method of ZnS microspheres:

[0028] Weigh 3.00g polyvinylpyrrolidone, 100mL deionized water, fully dissolve polyvinylpyrrolidone in deionized water; obtain a uniform solution, stir and heat to 75°C; weigh 3.75g thioacetamide, add to the reaction system; measure Add 0.07mL of concentrated nitric acid to the reaction system; weigh 8.92g of zinc nitrate hexahydrate, dissolve it in 5mL of deionized water in advance, then quickly add to the reaction system, stir at 1000rpm for 3min; reduce the stirring speed to 500rpm, The reaction was stirred at ℃ for 3h. The product was centrifuged, washed with water three times, dried and ground to obtain ZnS microspheres with a particle size of 320 nm.

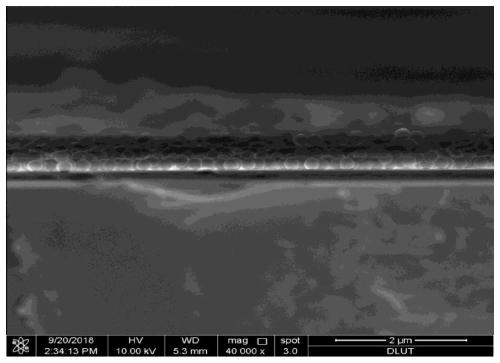

[0029] A green structural color coating based on high refractive index microsphere Mie scattering, comprising the following components by mass: 5 parts of ZnS microspheres with a particle diameter of 320nm, 90 parts of deionized water, 1 part of dodecylbenzene Sodium sulfo...

Embodiment 2

[0035] By changing the amount of zinc nitrate hexahydrate weighed in the method for preparing ZnS microspheres in Example 1 to 5.95 g, ZnS microspheres with a particle size of 280 nm can be prepared.

[0036] A blue structural color coating based on high refractive index microsphere Mie scattering, comprising the following components by mass: 10 parts of ZnS microspheres with a particle diameter of 280nm, 85 parts of deionized water, 2 parts of dodecyl Sodium benzenesulfonate, 3 parts polyvinyl alcohol.

[0037] The structural color coating is weighed and mixed in a beaker by weighing the above-mentioned components in parts by mass, the stirring speed is adjusted to 700rpm, the magnetic force is stirred for 30min, and the ultrasonic dispersion is for 60min, so that each component is fully and uniformly dispersed in deionized water. Get structural color paint.

[0038] The structural color paint is sprayed with a spray gun, and the selected base is a metal plate. By spraying,...

Embodiment 3

[0040] Preparation method of CdS microspheres:

[0041] Weigh 6.00g of polyvinylpyrrolidone, dissolve it in 150mL of diethylene glycol solution, add 7.71g of chromium nitrate tetrahydrate and 1.90g of thiourea, and stir until all the powders are completely dissolved. Heat the solution to 150-160°C, keep it warm for 5 hours, then cool it down to room temperature naturally, wash the product with ethanol and water three times after centrifugation, dry and grind to obtain CdS microspheres with a particle size of 390nm.

[0042] A red structural color coating based on high refractive index microsphere Mie scattering, comprising the following components by mass: 1 part of CdS microspheres with a particle diameter of 390nm, 90 parts of ethanol, 4 parts of sodium cetyl sulfate, 5 parts water glass.

[0043] The structural color coating is obtained by weighing the above-mentioned components by mass respectively, mixing them in a beaker, adjusting the stirring speed to 700rpm, magnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com