A kind of molybdenum-copper alloy with low molybdenum content and preparation method thereof

A molybdenum-copper alloy, content technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of low-molybdenum-content molybdenum-copper alloy microstructure, difficulty in fully guaranteeing performance, large fluctuations in product quality, etc., and achieve high surface potential energy , Shorter sintering time, better fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

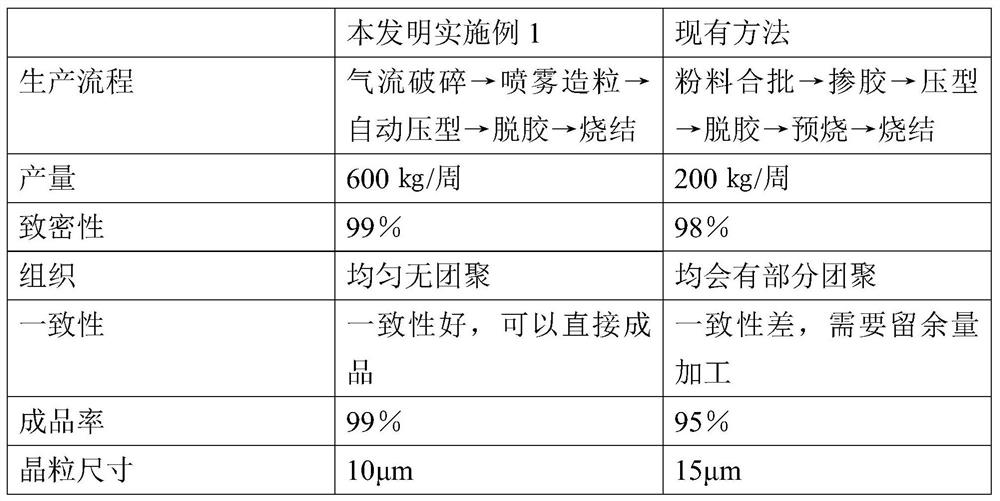

Embodiment 1

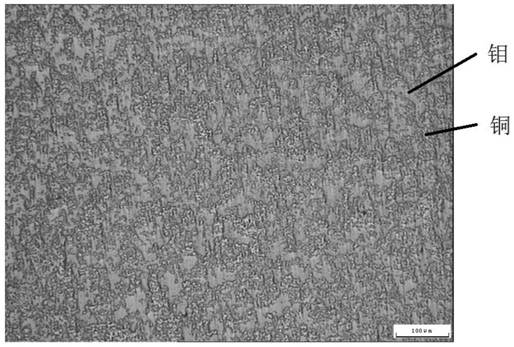

[0032] The preparation of embodiment 1Mo50Cu50 alloy comprises steps:

[0033] 1. Molybdenum powder treatment

[0034] The prepared Fisherman's particle size is 4.0μm, and the bulk density is 1.3g / cm 3 The molybdenum powder is crushed by a jet crusher to obtain non-agglomerated molybdenum powder.

[0035] 2. Spray granulation

[0036] Take the Fischer particle size as 4.0μm and the bulk density as 3.0g / cm 3The superfine copper powder of step 1 is mixed with the non-agglomerated molybdenum powder of step 1, water and PEG20000 binding agent to be slurry. Among them: the mass ratio of non-agglomerated molybdenum powder: copper powder is 1:1, the amount of water added is 25% of the total mass of non-agglomerated molybdenum powder and copper powder; the amount of binder added is the total mass of non-agglomerated molybdenum powder and copper powder 3%. The slurry is spray-dried and granulated under a nitrogen protective atmosphere. The nozzle diameter used for spray granulatio...

Embodiment 2

[0048] The preparation of embodiment 2Mo30Cu70 alloy

[0049] 1. Molybdenum powder treatment

[0050] The prepared Fisherman's particle size is 3.5μm, and the bulk density is 1.2g / cm 3 The molybdenum powder is crushed by a jet crusher to obtain non-agglomerated molybdenum powder.

[0051] 2. Spray granulation

[0052] Take the Fischer particle size as 3.5μm and the bulk density as 2.5g / cm 3 The superfine copper powder of step 1 is mixed with the non-agglomerated molybdenum powder of step 1, water and PEG20000 binding agent to be slurry. Among them: the mass ratio of non-agglomerated molybdenum powder: copper powder is 3:7, the amount of water added is 20% of the total mass of non-agglomerated molybdenum powder and copper powder; the amount of binder added is the total mass of non-agglomerated molybdenum powder and copper powder 2%. The slurry is spray-dried and granulated under a nitrogen protective atmosphere. The diameter of the spray granulation nozzle is 0.96mm, the s...

Embodiment 3

[0061] The preparation of embodiment 3Mo10Cu90 alloy

[0062] 1. Molybdenum powder treatment

[0063] The prepared Fisherman's particle size is 3.0μm, and the bulk density is 1.0g / cm 3 The molybdenum powder is crushed by a jet crusher to obtain non-agglomerated molybdenum powder.

[0064] 2. Spray granulation

[0065] Take the Fischer particle size as 3.0μm, and the bulk density as 2.0g / cm 3 The superfine copper powder of step 1 is mixed with the non-agglomerated molybdenum powder of step 1, water and binding agent are mixed into slurry. Among them: the mass ratio of non-agglomerated molybdenum powder: copper powder is 1:9, the amount of water added is 15% of the total mass of non-agglomerated molybdenum powder and copper powder; the amount of binder added is the total mass of non-agglomerated molybdenum powder and copper powder 1%. The slurry is spray-dried and granulated under a nitrogen protective atmosphere. The diameter of the spray granulation nozzle is 0.8mm, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com