Method for modifying surface of carbon nanotube with nanosilver, and application of nanosilver-modified carbon nanotube

A carbon nanotube, modification and modification technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of carbon nanotube length reduction, multi-walled carbon nanotube fracture, etc., achieve short chemical reaction time, The chemical reaction time is safe and the effect of maintaining the characteristics of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

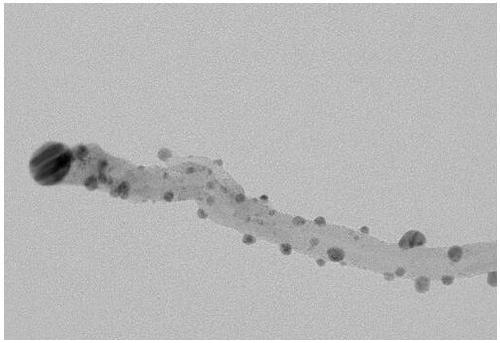

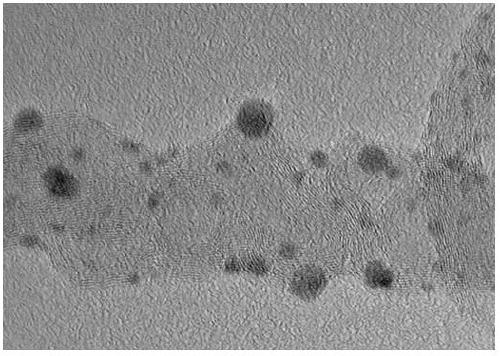

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of method for nano-silver modification modified carbon nanotube surface, concrete steps are as follows:

[0027] (1) Dissolving the functional treatment agent (sodium dodecylbenzene sulfonate) in ethanol solution to obtain a surface functional treatment solution, wherein the functional treatment agent (sodium dodecylbenzene sulfonate) in the surface functional treatment solution ) with a total concentration of 2 mol / L; the carbon nanotubes were added to the surface functionalization treatment solution, and the carbon nanotubes were separated from the solid and liquid after ultrasonic treatment in an ice bath for 2 h, washed with deionized water and then washed with ethanol The carbon nanotubes to the washing solution are neutral to obtain the surface functionalized carbon nanotubes; wherein the solid-liquid ratio g:mL of the carbon nanotubes and the surface functionalization treatment solution is 1:500, the frequency of the ultrasonic wave is 50 kHz,...

Embodiment 2

[0031] Embodiment 2: a kind of method for nano-silver modification modified carbon nanotube surface, concrete steps are as follows:

[0032] (1) Dissolving the functional treatment agent (sodium dodecyl sulfonate and sodium dodecylbenzene sulfonate) in ethanol solution to obtain a surface functional treatment solution, wherein the functional treatment agent in the surface functional treatment solution ( Sodium dodecylsulfonate and sodium dodecylbenzenesulfonate) with a total concentration of 3 mol / L; the carbon nanotubes were added to the surface functionalization treatment solution and solidified after ultrasonic treatment for 3 h under ice bath conditions. The carbon nanotubes are separated from the liquid, and after washing with deionized water, the carbon nanotubes are washed with ethanol until the washing liquid is neutral to obtain the surface functionalized carbon nanotubes; wherein the solid-liquid ratio of the carbon nanotubes to the surface functionalization treatment...

Embodiment 3

[0036] Embodiment 3: a kind of nano-silver modified method for modifying the surface of carbon nanotubes, the specific steps are as follows:

[0037](1) Dissolving the functional treatment agent (sodium dodecylbenzene sulfonate) in ethanol solution to obtain a surface functional treatment solution, wherein the functional treatment agent (sodium dodecylbenzene sulfonate) in the surface functional treatment solution ) at a concentration of 1 mol / L; carbon nanotubes were added to the surface functionalization treatment solution, and the carbon nanotubes were separated from the solid and liquid after ultrasonic treatment in an ice bath for 1 h, and the carbon nanotubes were washed with deionized water and then ethanol. The nanotubes to the washing solution are neutral to obtain the surface functionalized carbon nanotubes; wherein the solid-liquid ratio g:mL of the carbon nanotubes and the surface functionalized treatment solution is 1:100, the frequency of the ultrasonic wave is 25...

PUM

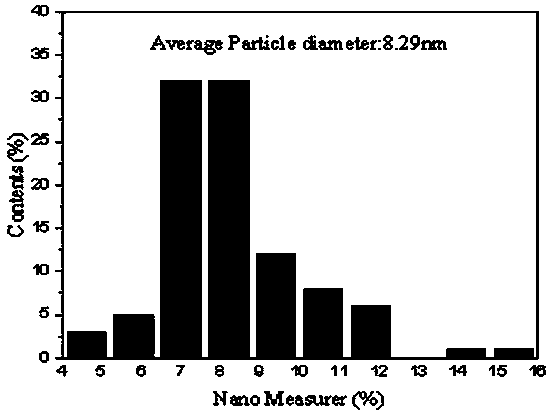

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com