Preparation method of resin for removing calcium, magnesium and silicon prepared by PAC flocculant

A flocculant, calcium-magnesium-silicon technology, applied in chemical instruments and methods, cation exchange materials, ion exchange water/sewage treatment, etc., can solve the problems of no unified measurement standard and unstable effect, and save operation and material costs , increase the removal effect and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

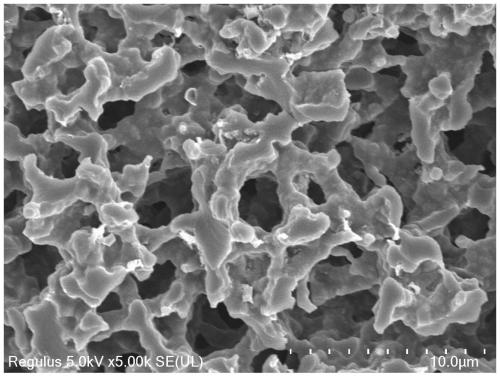

[0023] A kind of preparation method of the resin that is used to remove calcium magnesium silicon by PAC flocculant, is raw material with cation exchange resin, comprises the following steps:

[0024] Step 1: Pretreatment and cleaning of the cation exchange resin with deionized water;

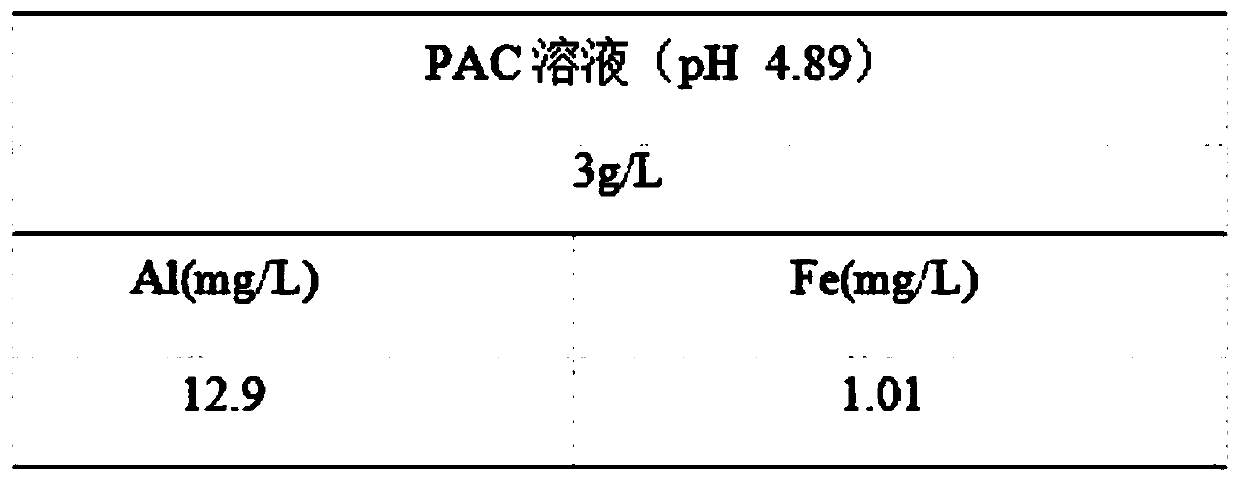

[0025] Step 2: Prepare a PAC flocculant with a mass fraction of 8%, mix according to the ratio of cation exchange resin: PAC flocculant = 1:50, and then uniformly stir for 3 hours to obtain a mixture;

[0026] Step 3: Drain the liquid in the mixture obtained in Step 2 to obtain Resin 1, then add a mixed solution of 1% NaOH and 1% NaCl in mass fraction to Resin 1, mix and uniformly stir for 2 hours to obtain the mixture ;

[0027] Step 4: Discharge the mixed solution with a mass fraction of 1% NaOH and a mass fraction of 1% NaCl in the mixture formed in step 3 to obtain resin 2, then wash resin 2 with polar solvent ethanol, take out and clean The resin II is then dried and cooled to obtain the...

Embodiment 2

[0032] A kind of preparation method of the resin that is used to remove calcium magnesium silicon by PAC flocculant, is raw material with cation exchange resin, comprises the following steps:

[0033] Step 1: Pretreatment and cleaning of the cation exchange resin with deionized water;

[0034] Step 2: Prepare a PAC flocculant with a mass fraction of 9%, mix according to the ratio of cation exchange resin: PAC flocculant = 1:50, and then uniformly stir for 3.5 hours to obtain a mixture;

[0035] Step 3: Drain the liquid in the mixture obtained in Step 2 to obtain Resin 1, then add a mixed solution of 1% NaOH and 1% NaCl in mass fraction to Resin 1, mix and uniformly stir for 2.5 hours to obtain mixture;

[0036] Step 4: Discharge the mixed solution with a mass fraction of 1% NaOH and a mass fraction of 1% NaCl in the mixture formed in step 3 to obtain resin 2, then wash resin 2 with polar solvent ethanol, take out and clean The resin II is then dried and cooled to obtain the ...

Embodiment 3

[0041] A kind of preparation method of the resin that is used to remove calcium magnesium silicon by PAC flocculant, is raw material with cation exchange resin, comprises the following steps:

[0042] Step 1: Pretreatment and cleaning of the cation exchange resin with deionized water;

[0043] Step 2: Prepare a PAC flocculant with a mass fraction of 10%, mix according to the ratio of cation exchange resin: PAC flocculant = 1:50, and then uniformly stir for 4 hours to obtain a mixture;

[0044] Step 3: Drain the liquid in the mixture obtained in Step 2 to obtain Resin 1, then add a mixed solution of 1% NaOH and 1% NaCl in mass fraction to Resin 1, mix, and stir uniformly for 3 hours to obtain the mixture ;

[0045] Step 4: Discharge the mixed solution with a mass fraction of 1% NaOH and a mass fraction of 1% NaCl in the mixture formed in step 3 to obtain resin 2, then wash resin 2 with polar solvent ethanol, take out and clean The resin II is then dried and cooled to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com