Stabilizer for promoting the formation of weather-resistant steel rust layer and preparation method of weather-resistant steel rust layer

A stabilizer and weather-resistant steel technology, applied in the coating process of metal materials, etc., can solve the problems of uneven rust layer formation and high cost, achieve uniform corrosion, easy operation, and prevent the loss of rust liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Embodiment also provides a kind of preparation method of weather-resistant steel rust layer, described method comprises the steps:

[0037] Step 1, removing the scale on the surface of the steel substrate: removing the scale on the surface of the steel substrate by shot blasting or sandblasting;

[0038] Step 2, preparing the above-mentioned stabilizer: nano-α-FeOOH, nano-γ-FeOOH, nano-Fe 3 o 4 、CuSO 4 and Cr 2 (SO 4 ) 3 Uniformly dispersed in aqueous acrylic acid solution to obtain the stabilizer;

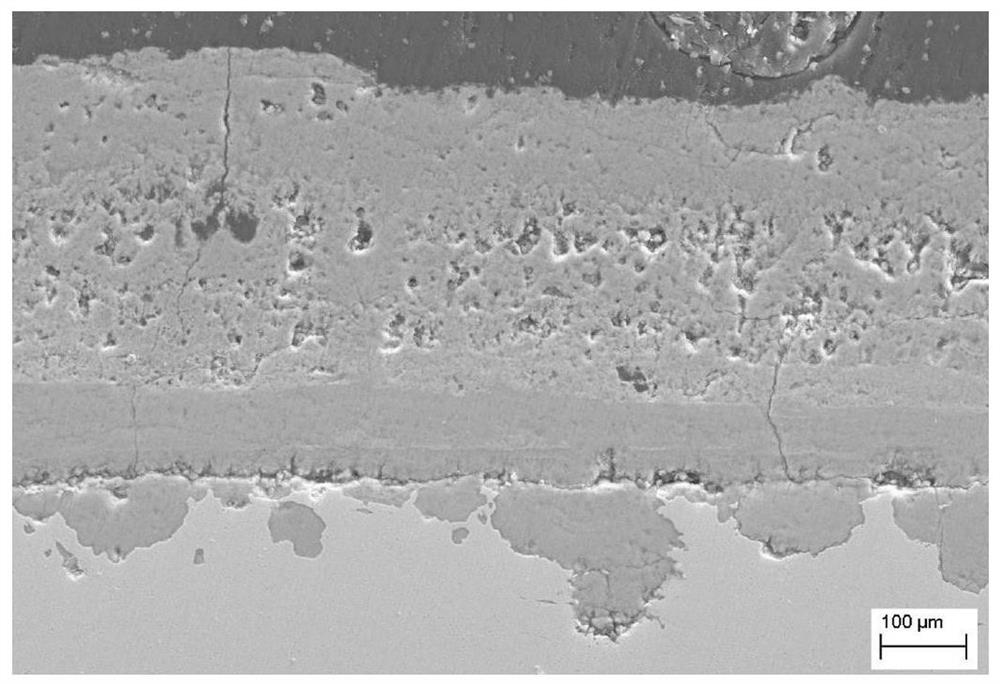

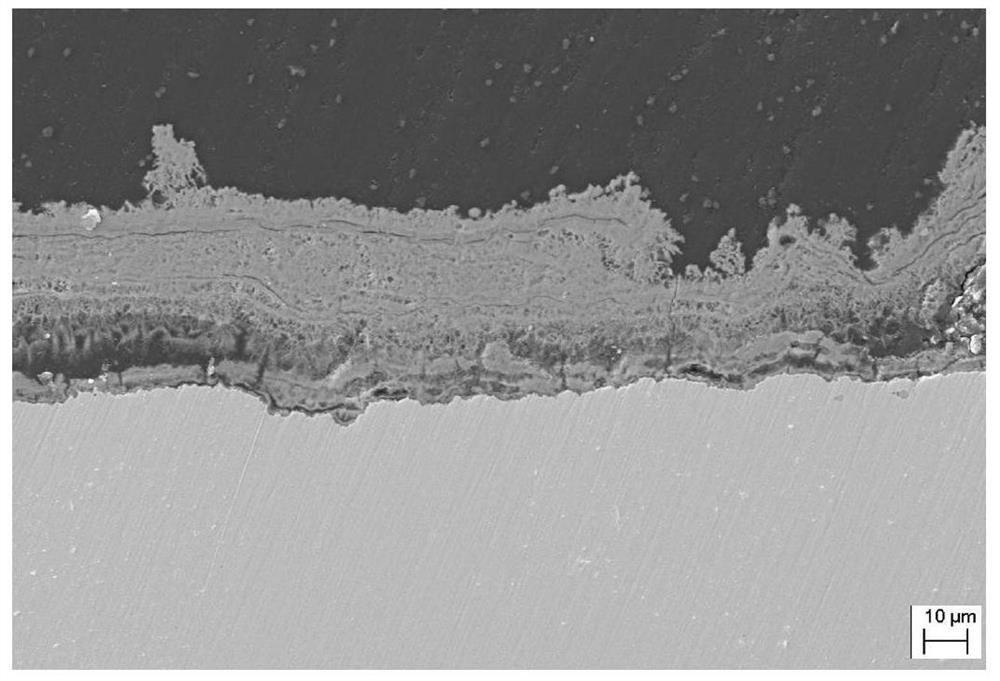

[0039] Step 3, promoting the formation of a stable rust layer on the weathering steel: coating the formulated stabilizer on the surface of the weathering steel, and drying to obtain a stabilizer formation layer; during the subsequent service of the weathering steel, water and oxygen in the air permeate Form a layer through the stabilizer, and electrochemically corrode the weathering steel to form a stable rust layer;

[0040] After the uniform rust layer is formed, t...

Embodiment 1

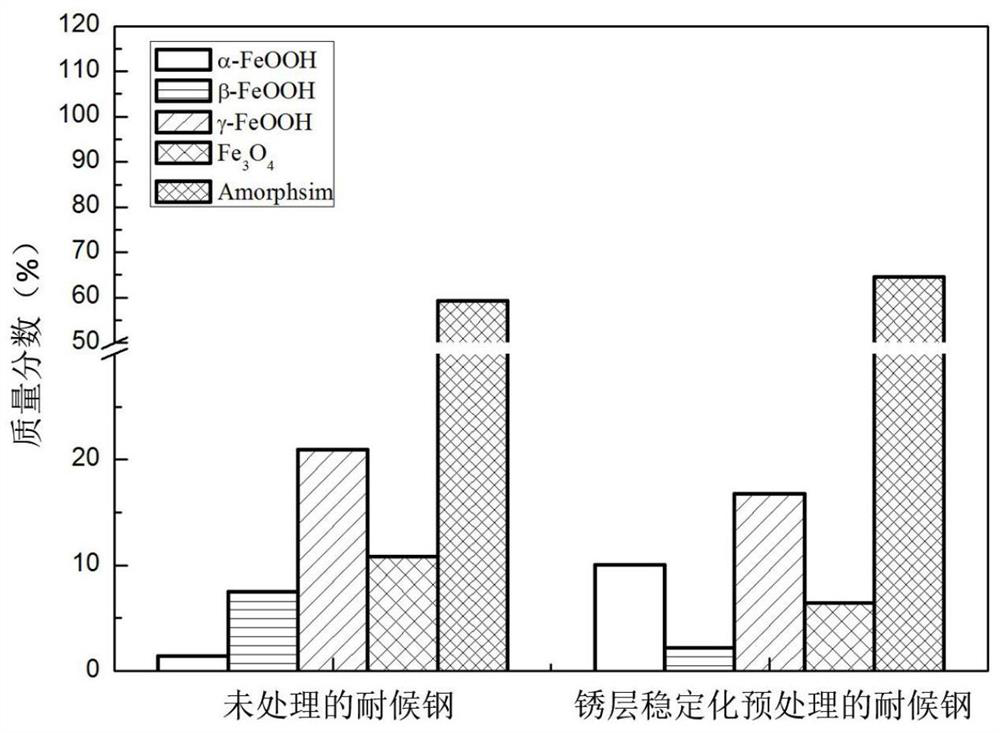

[0045] In this embodiment, the verification of the stabilizer based on the stabilized rust layer color to promote the formation of the weather-resistant steel rust layer in the atmospheric exposure experiment includes the following steps:

[0046] S1. Cut the weathering steel into 60mm×40mm. After degreasing with acetone, the surface is sandblasted and cleaned with absolute ethanol and dried.

[0047] S2. Prepare a stabilizer that promotes the formation of weather-resistant steel rust layer: nano-α-FeOOH, nano-γ

[0048] -FeOOH, Nano Fe 3 o 4 、CuSO 4 and Cr 2 (SO 4 ) 3 uniformly dispersed in aqueous acrylic acid solution to obtain the stabilizer; the weight percent of the stabilizer is: 3% nanometer α-FeOOH, 0.5% nanometer γ-FeOOH, 2% nanometer Fe 3 o 4 , 2% CuSO 4 and 0.5% Cr 2 (SO 4 ) 3 , and the balance is aqueous acrylic acid solution. The prepared stabilizer is sprayed on the surface of the weathering steel sample (film thickness 200 μm), and dried in the air ...

Embodiment 2

[0054] The verification of the stabilizer based on the stabilized rust layer color of the present embodiment to promote the formation of the weather-resistant steel rust layer in the atmospheric exposure experiment, its steps and effects are basically the same as in Example 1, except that:

[0055] The weight percent of described stabilizer is:

[0056] 1% Nano α-FeOOH, 10% Nano γ-FeOOH, 10% Nano Fe 3 o 4 , 3% CuSO 4 and 3% Cr 2 (SO 4 ) 3 , and the balance is aqueous acrylic acid solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com