Method and device for recycling copper from browning liquid and additive

A technology of additives and browning liquid, applied in the field of PCB waste liquid treatment, can solve the problems of low copper ion recovery efficiency, etc., and achieve the effects of convenient operation, reduction of copper content, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

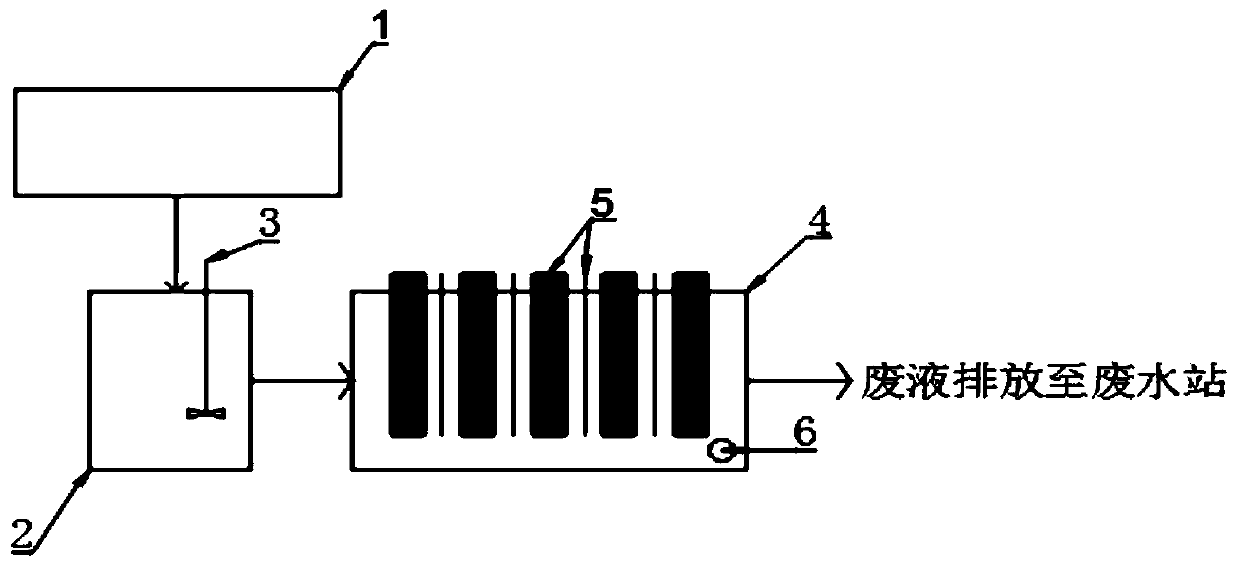

Image

Examples

Embodiment 1

[0061] The additive raw material for electrolysis includes the following components:

[0062] Polyethylene glycol 9g, polyacrylamide 2g, sodium hypochlorite 5g, sodium polydithiodipropane sulfonate 8g, sodium chloride 10g.

[0063] Add each raw material into the additive mixing tank according to the above dosage, add 1L of water and stir evenly to obtain an aqueous solution of the additive for electrolysis. There is 2000L of electrolytic browning waste liquid in the waste liquid storage tank, in which the copper content is 21.6g / L, and the theoretical copper production is 43.2Kg. Add 1L of the electrolytic additive aqueous solution into the waste liquid storage tank, and mix evenly with the help of a stirring device. Pump all the evenly mixed electrolytic browning waste liquid in the waste liquid storage tank into the electrolytic cell for electrolytic treatment. The electrolysis treatment condition is, the current density is 300A / m 2 , under aeration. Finally, the actuall...

Embodiment 2

[0065] The additive raw material for electrolysis includes the following components:

[0066] Polyethylene glycol 8g, polyacrylamide 1g, sodium hypochlorite 4g, sodium polydithiodipropane sulfonate 7g, sodium chloride 9g.

[0067] Add each raw material into the additive mixing tank according to the above dosage, add 1L of water and stir evenly to obtain an aqueous solution of the additive for electrolysis. There is 2000L of electrolytic browning waste liquid in the waste liquid storage tank, in which the copper content is 20.2g / L, and the theoretical copper production is 40.4Kg. Add 1L of the electrolytic additive aqueous solution into the waste liquid storage tank, and mix evenly with the help of a stirring device. Pump all the evenly mixed electrolytic browning waste liquid in the waste liquid storage tank into the electrolytic cell for electrolytic treatment. The electrolytic treatment condition is, the current density is 250A / m 2 , under aeration. Finally, the actually...

Embodiment 3

[0069] The additive raw material for electrolysis includes the following components:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com