Multi-parameter rapid measuring and controlling device for ultrasonic motor and measuring and controlling method thereof

A technology of ultrasonic motors and measurement and control devices, which is applied in the direction of measuring devices, motor generator testing, computer control, etc., can solve problems such as insufficient test parameters and control parameters, limited accuracy and real-time performance, and constraints on motor analysis and control, etc., to achieve Meet the comprehensive and fast test requirements, high precision and automation, and strong real-time performance of software and hardware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

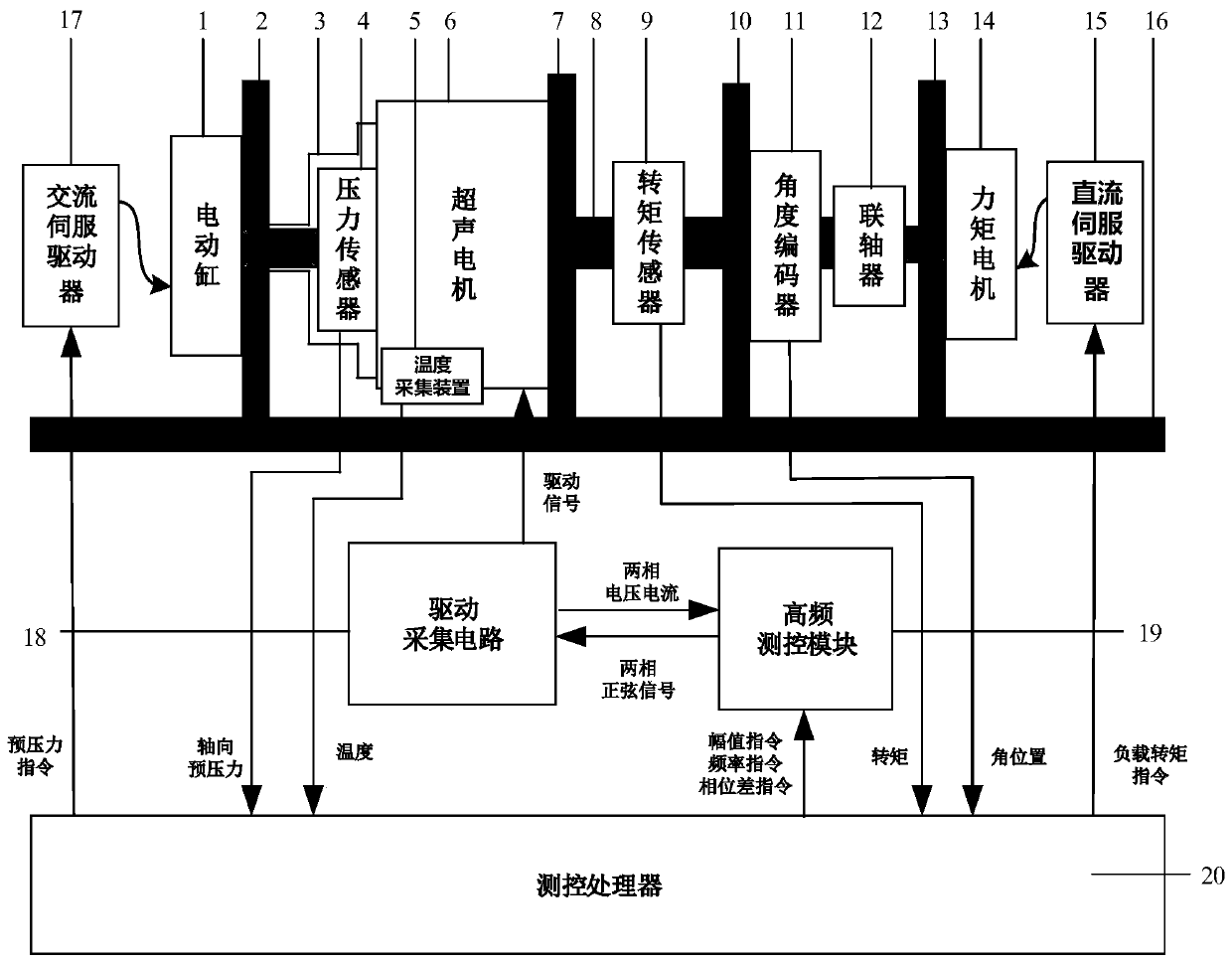

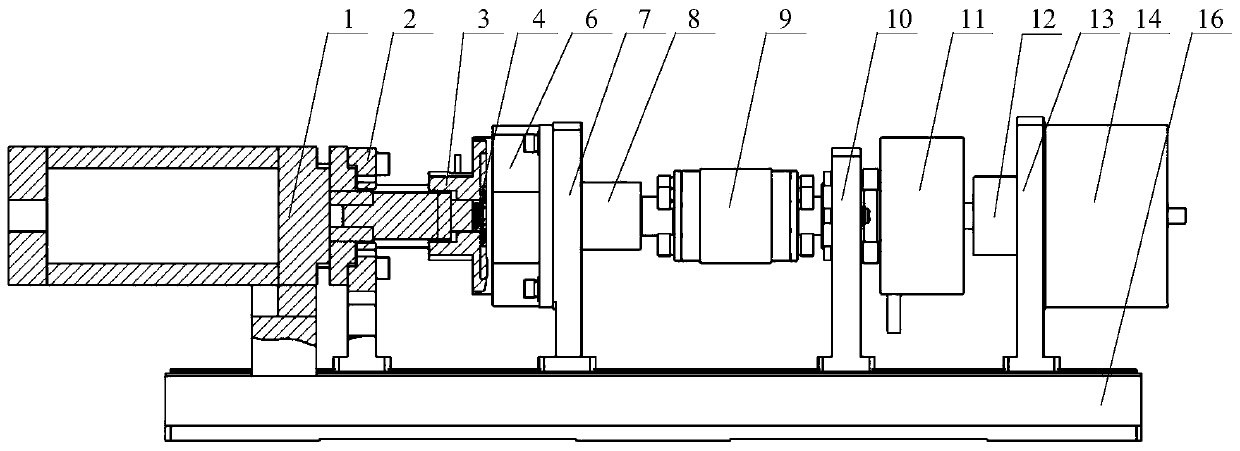

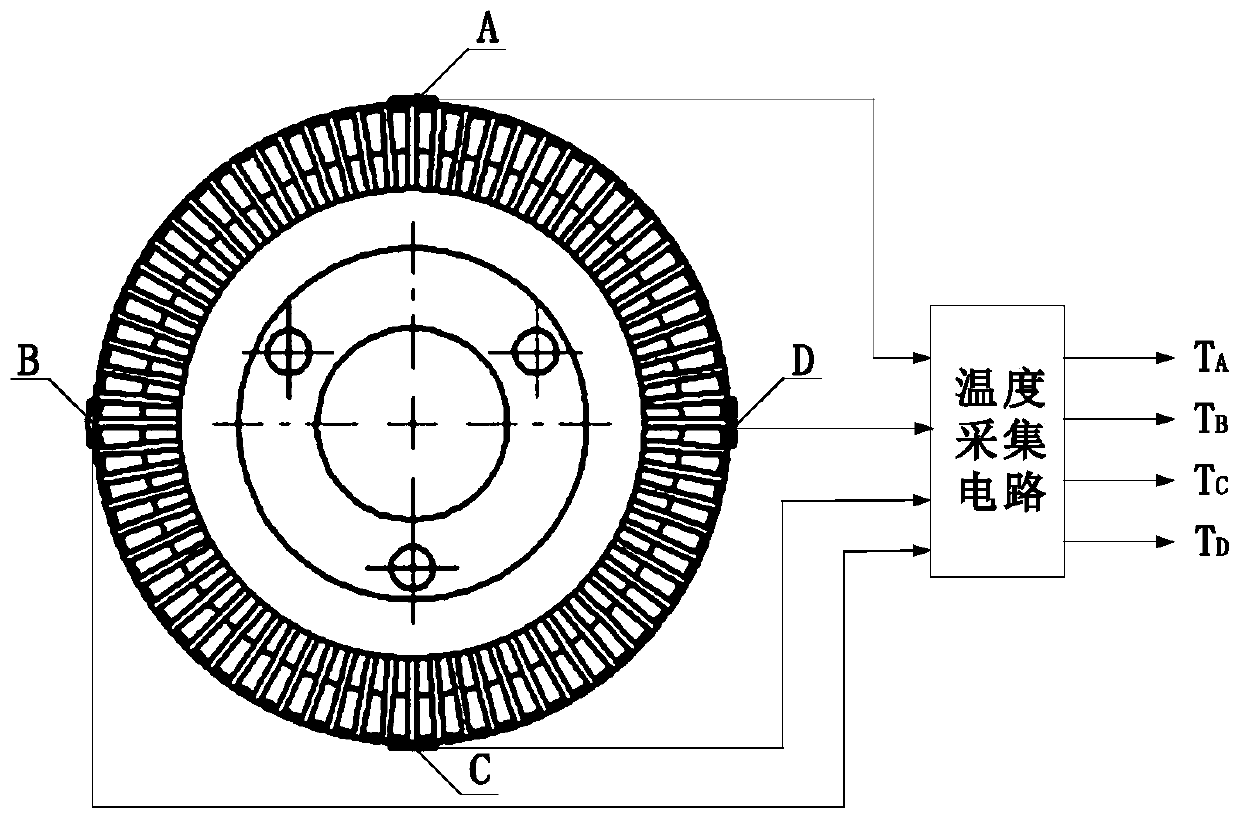

[0045] Such as figure 1 , figure 2 As shown, an ultrasonic motor multi-parameter fast measurement and control device includes: electric cylinder 1, mounting frame I2, annular sleeve 3, pressure sensor 4, temperature acquisition device 5, ultrasonic motor 6, mounting frame II7, rotary shaft 8, Torque sensor 9, mounting frame III 10, angle encoder 11, coupling 12, mounting frame Ⅳ 13, torque motor 14, DC servo drive 15, base 16, AC servo drive 17, drive acquisition circuit 18, high-frequency measurement and control module 19. The measurement and control processor 20.

[0046] Such as figure 1 , figure 2 As shown, the installation frame I2, the installation frame II7, the installation frame III10, and the installation frame IV13 are separated in a straight line, and are fixed and fitted on the base 16 by bolts;

[0047] The electric cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com