A method of manufacturing a grain boundary layer capacitor

A manufacturing method and capacitor technology, applied in the direction of capacitors, fixed capacitors, components of fixed capacitors, etc., can solve the problems of difficult to accurately control technology, large differences in capacitors, affecting stability, etc., to achieve good consistency and improved resistance value. , The effect of improving the consistency of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

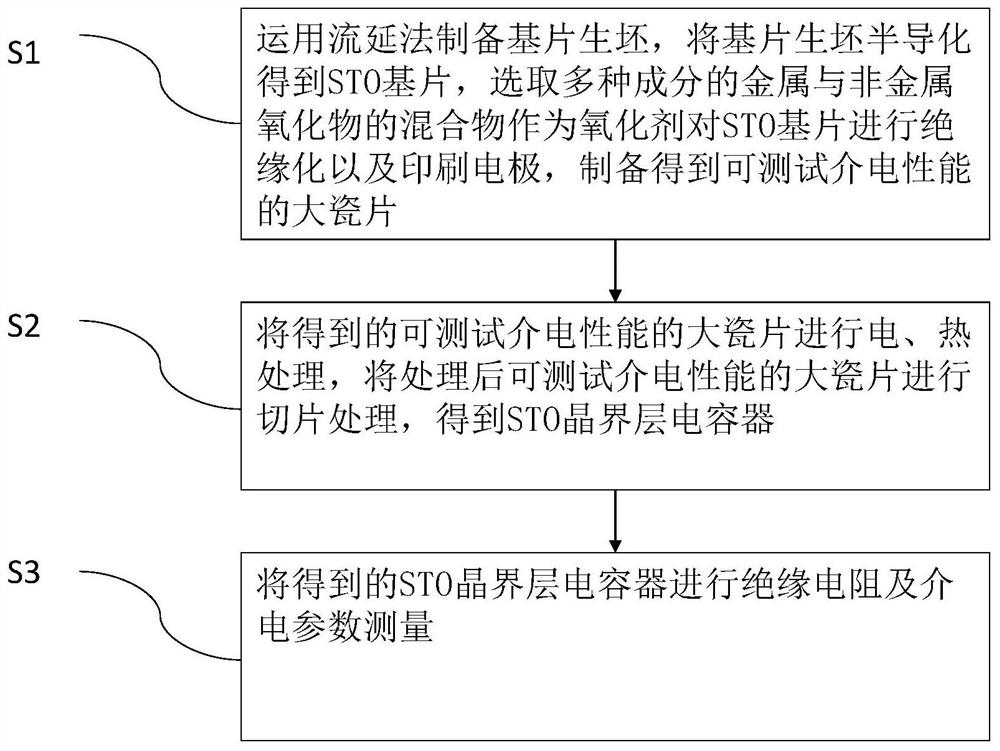

[0032] The present invention will be described in further detail below in conjunction with accompanying drawing, the present invention provides a kind of manufacturing method of grain boundary layer capacitor, as figure 1 As shown, the method includes the following steps:

[0033] S1. Use the tape casting method to prepare the substrate green body, semiconduct the substrate green body to obtain the STO substrate, select a mixture of metal and non-metal oxides with various components as the oxidant to insulate the STO substrate and print electrodes , to prepare a large ceramic piece that can be tested for dielectric properties;

[0034] Wherein, the step S1 includes the following steps:

[0035] S11, using tape casting method to prepare green body, wherein, using SrCO 3 and TiO 2 As the main ingredient, defoamer and dispersant are added, and 1% of the weight of the main ingredient is taken each, and the casting slurry is obtained by ball milling in a planetary ball mill, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com