Solid state electrolyte and solid state battery

A solid-state electrolyte and solid-state battery technology, which is applied in the direction of batteries with solid electrolytes, non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, etc., can solve the practical requirements that cannot be met, the lithium ion migration rate cannot be improved, and the conductivity of solid electrolytes is low. and other problems, to achieve the effect of improving electrical performance, good chemical stability, and solving poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

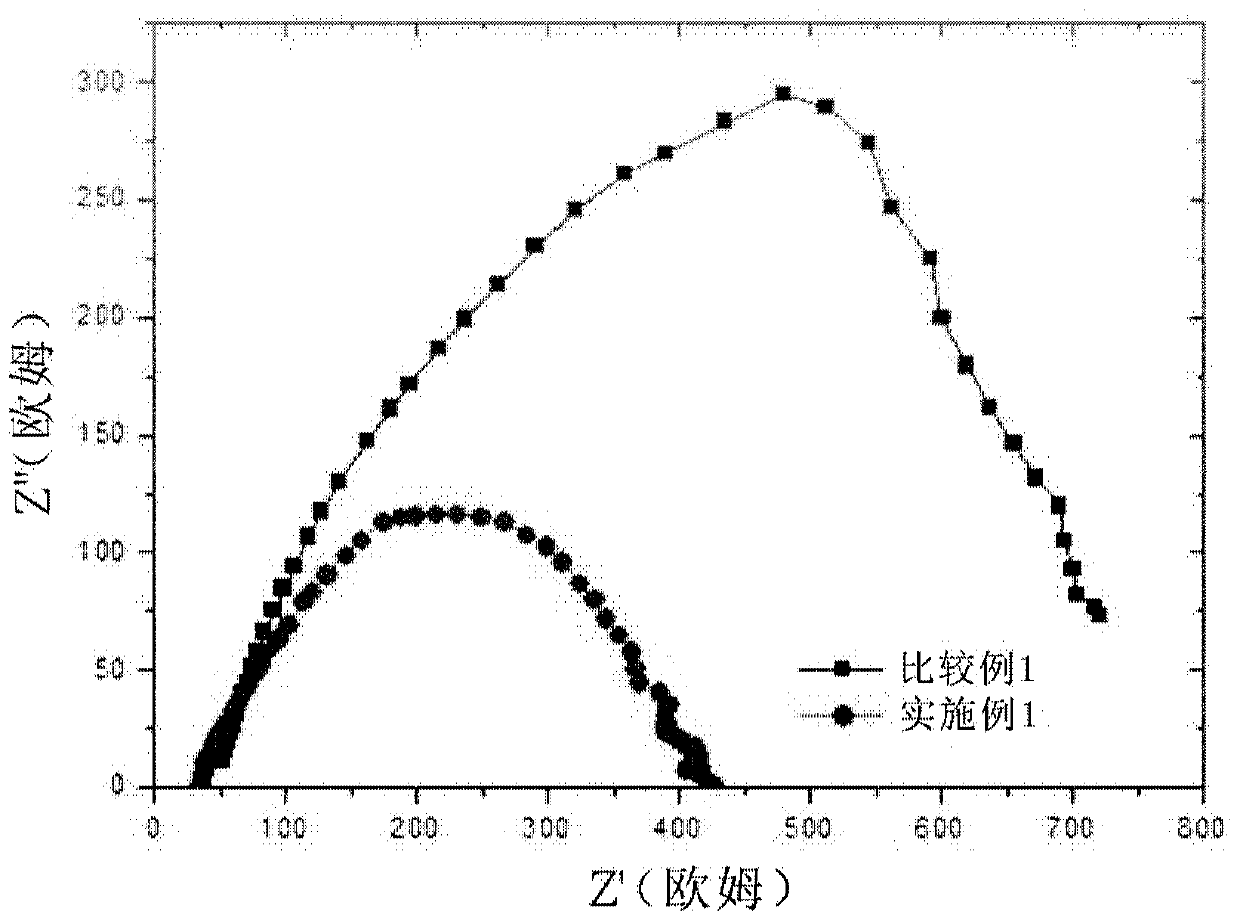

Embodiment 1

[0052] Lithium hydroxide (LiOH), lanthanum oxide (La 2 o 3 ), zirconia (ZrO 2 ) and tantalum oxide (Ta 2 o 5 ) mixed with lithium sulfide (LiS) (the above raw materials are formulated with reference to the ratio of x=0.1 and y=0.65 in formula 1), 500 grams of isopropanol (IPA) was added, and ground for 24 hours by ball milling, and the above materials were uniformly mixed Then the precursor slurry can be obtained. Next, the precursor slurry is dried to obtain dry precursor powder. Then, the dried precursor powder was put into an alumina crucible, and sintered in a nitrogen atmosphere at a temperature of 950 °C for 6 hours, and the obtained powder was a sulfur-doped lithium lanthanum zirconium tantalum oxide (LLZTO) solid electrolyte powder ( Sulfur content is 5.73 mole percent).

Embodiment 2

[0054] Prepare the sulfur-doped lithium lanthanum zirconium tantalum oxide (LLZTO) solid electrolyte powder of Example 2 according to a preparation procedure similar to that of Example 1, the difference is that in Example 2, each raw material is x= 0.1, y = 1.2 ratio preparation. Therefore, the powder obtained after sintering is sulfur-doped lithium lanthanum zirconium tantalum oxide (LLZTO) solid electrolyte powder (sulfur content is 11.11 mole percent).

Embodiment 3

[0056] Prepare the sulfur-doped lithium lanthanum zirconium tantalum oxide (LLZTO) solid electrolyte powder of Example 3 according to a preparation procedure similar to that of Example 1, the difference is that in Example 3, each raw material is x= 0.1, y=3 ratio preparation. Therefore, the powder obtained after sintering is sulfur-doped lithium lanthanum zirconium tantalum oxide (LLZTO) solid electrolyte powder (sulfur content is 33.33 mole percent).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com