Surface physically modified polyarylether bone implant material containing phthalazinone biphenyl structure and preparation method thereof

A xinone biphenyl, surface physics technology, applied in the direction of prosthesis, coating, tissue regeneration, etc., can solve the low limit of biocompatibility and osteogenic activity, affect the life of PEEK implants, poor osteogenic activity Ideal and other issues, to achieve the effect of improving biocompatibility and osteogenic activity, low cost, and maintaining biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In the first step, the PPBES powder is hot-pressed to obtain a PPBES part;

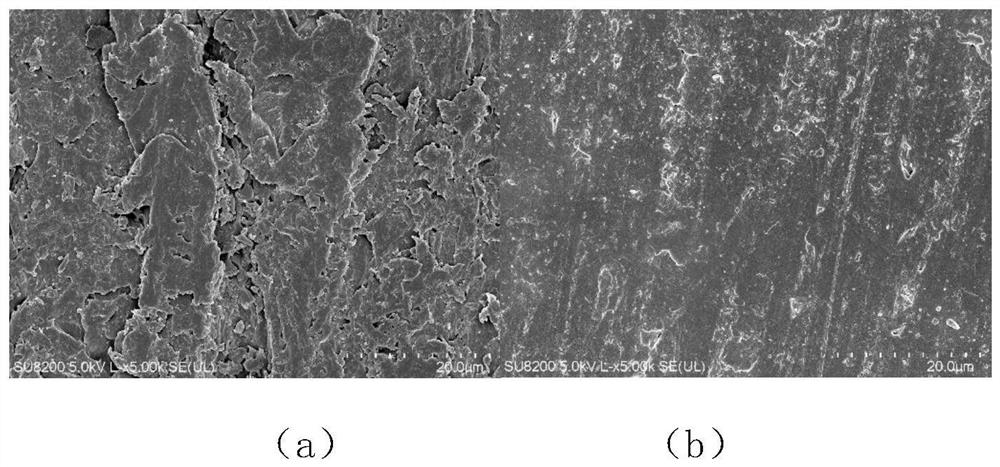

[0047] In the second step, the PPBES parts are polished with 400-mesh and 2000-mesh sandpaper to make the surface uniform, and PPBES parts with different surface roughness are obtained, PPBES-400 and PPBES-2000; then the polished PPBES parts, Wash with deionized water, ethanol, acetone, and deionized water respectively, and dry for later use;

[0048] In the third step, the PPBES-400 and PPBES-2000 parts were respectively immersed in a PBS solution of BMP-2 with a pH of 7.4, and magnetically stirred at room temperature for 24 hours.

[0049] Finally, the parts were removed from the solution, dried in a 37°C blast oven, and placed in a 4°C refrigerator for later use.

Embodiment 2

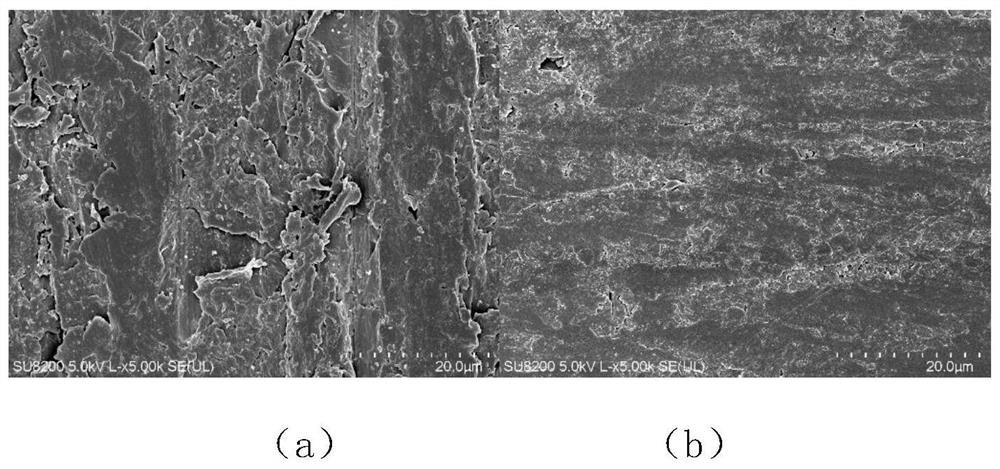

[0051] The PPBES among the embodiment one is changed into PPENK, and it is the same as the embodiment one with the step

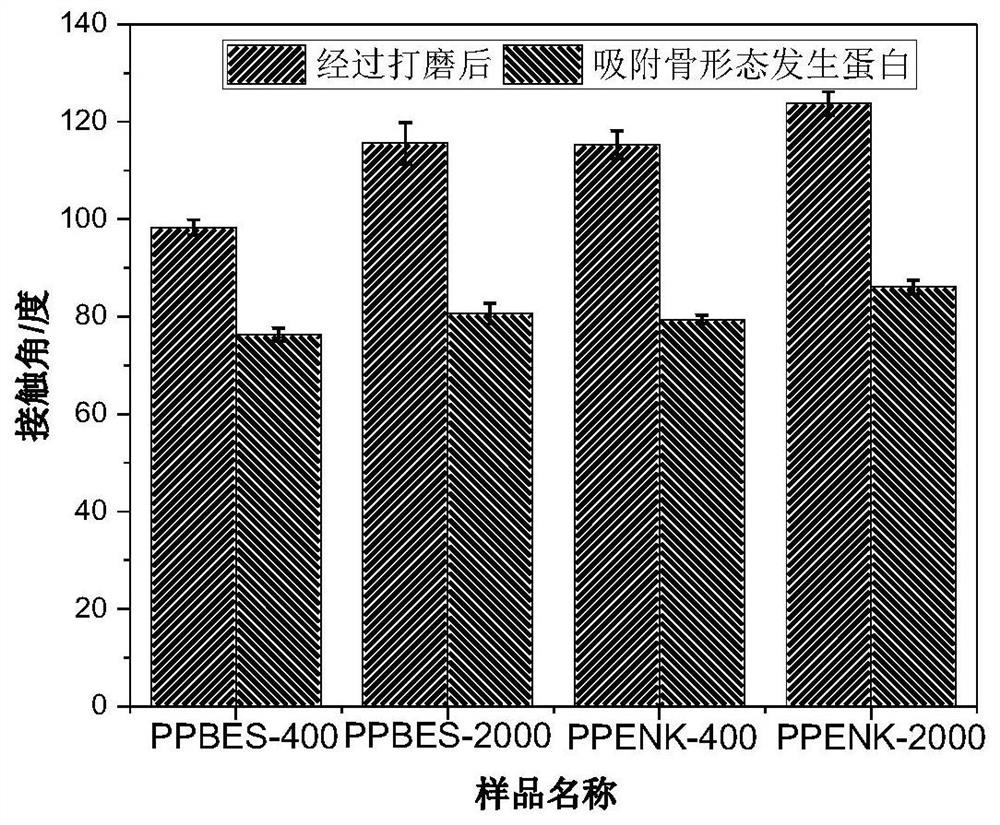

[0052] The surface morphology of polyarylether materials with different roughness was observed by cold field scanning electron microscope. The hydrophilicity and hydrophobicity of the sample surface were characterized by a water contact angle meter. The surface BMP-2 content was determined by testing the loading efficiency and in vitro release efficiency of BMP-2 by using the BMP-2 content kit. MC3T3-E1 mouse embryonic osteoblast precursor cells were used as test cells to characterize the biocompatibility of the material.

[0053] The surface prepared by the above method has PPBES and PPENK parts with osteogenic active protein, and its properties are as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com