Efficient catalytic ozonation technology and treatment system thereof

A technology of ozone catalytic oxidation and catalytic oxidation, which is applied in the direction of oxidized water/sewage treatment, special compound water treatment, water/sewage treatment, etc., can solve the problems of limited efficiency, increase the contact area, improve the utilization rate of ozone, and improve efficiency and the effect of removing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

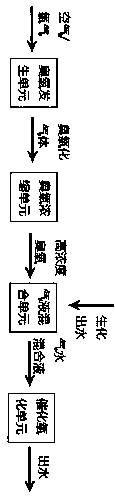

Image

Examples

Embodiment 1

[0030] The biochemical effluent COD of a coking wastewater biochemical pool is 130mg / L, which is treated by conventional ozone catalytic oxidation process:

[0031] 1. Produce ozone by high-voltage corona discharge through an ozone generator to obtain ozonated gas, the gas source is oxygen, and the ozone concentration in the obtained ozonated gas is 100mg / L.

[0032] 2. The ozonated gas produced in step 1 enters the ozone catalytic oxidation tower through aeration. The dosage of ozone is 75g / t of water, and catalytic oxidation reaction occurs through the action of the catalyst, and the wastewater residence time is 60min.

[0033] The COD of the effluent from the ozone catalytic oxidation tower can be reduced to 75mg / L, and the COD removal rate is 42.3%.

Embodiment 2

[0035] Adopt process of the present invention to process embodiment 1 waste water:

[0036] 1. Produce ozone by high-voltage corona discharge through an ozone generator to obtain ozonated gas, the gas source is oxygen, and the ozone concentration in the obtained ozonated gas is 100mg / L.

[0037] 2. The ozonized gas prepared in step 1 enters the ozone concentration unit through the pipeline. This unit adopts the principle of pressure swing adsorption to absorb the oxygen and other gases in the ozonized gas through the carbon molecular sieve adsorbent, and the obtained high-concentration ozone gas, the ozone concentration Increase by 6 times to 600mg / L. After the adsorbent is saturated, the adsorbed oxygen is released through pressure swing desorption to regenerate the adsorbent.

[0038] 3. Mix the high-concentration ozone gas obtained in step 2 with the wastewater through the dissolved air pump, the mixed gas-liquid ratio is 1:8, and the calculated ozone dosage per ton of wate...

Embodiment 3

[0042] The biochemical effluent COD of a coking wastewater biochemical pool is 150mg / L, which is treated by conventional ozone catalytic oxidation process:

[0043] 1. Produce ozone by high-voltage corona discharge through an ozone generator to obtain ozonated gas, the gas source is oxygen, and the ozone concentration in the obtained ozonated gas is 120mg / L.

[0044] 2. The ozonated gas produced in step 1 enters the ozone catalytic oxidation tower through aeration. The dosage of ozone is 107g / t of water. Catalyzed oxidation reaction occurs through the action of the catalyst, and the wastewater residence time is 80min.

[0045] The COD of the effluent from the ozone catalytic oxidation tower can be reduced to 86mg / L, and the COD removal rate is 42.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com