A combined process for treating heavy metal content in biogas slurry for watering tea gardens

A combined process and heavy metal technology, applied in filtration treatment, sedimentation treatment, water/sewage treatment, etc., can solve the problems of inability to achieve recycling, reduce heavy metals, waste of resources, etc., achieve correction accuracy, increase potassium content, and save The effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A combined process for treating heavy metal content in biogas slurry for watering tea gardens, comprising the following steps:

[0035] S1: The anaerobically fermented biogas slurry is separated by a solid-liquid separation device and then flows into the reaction tank. The biogas slurry is first stirred and then left to stand. and the organic matter layer were sampled three times according to the depth, and the density of heavy metals at each sampling point was measured;

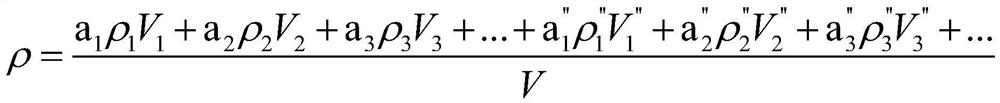

[0036] S2: Calculate the density of heavy metals in the biogas slurry according to the distribution of the volume of the biogas slurry in the reaction tank and the depth of the sampling point:

[0037]

[0038] Among them, a 1 、a 2 、a 3 Take the values 0.3, 0.4, 0.5 respectively;

[0039] a 1 ", a 2 ", a 3 "Respectively take values at 0.5, 0.6, 0.7,

[0040] ρ 1 , ρ 2 , ρ 3 are the measured values of heavy metal density at each sampling point in the clear water layer;

[0041] V ...

Embodiment 2

[0061] A combined process for treating heavy metal content in biogas slurry for watering tea gardens, comprising the following steps:

[0062] S1: The anaerobically fermented biogas slurry is separated by a solid-liquid separation device and then flows into the reaction tank. The biogas slurry is first stirred and then left to stand. and organic matter layers were sampled four times according to the depth, and the density of heavy metals at each sampling point was measured;

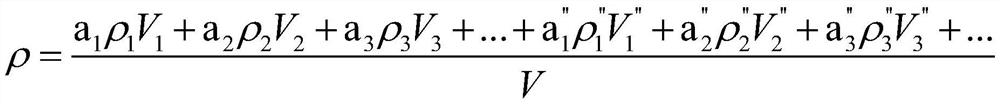

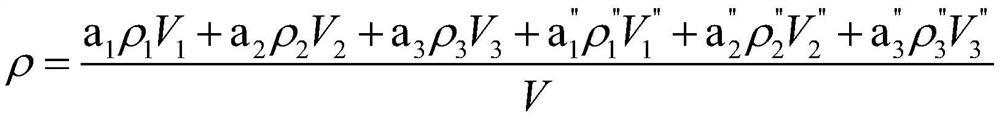

[0063] S2: Calculate the density of heavy metals in the biogas slurry according to the distribution of the volume of the biogas slurry in the reaction tank and the depth of the sampling point:

[0064]

[0065] Among them, a 1 、a 2 、a 3 、a 3 Take the values 0.3, 0.35, 0.4, 0.45 respectively;

[0066] a 1 ", a 2 ", a 3 ", a 4 "The value is 0.5, 0.55, 0.6, 0.65 respectively;

[0067] ρ 1 , ρ 2 , ρ 3 , ρ 4 are the measured values of heavy metal density at each sampling point in the clear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com