A modular continuous fuming production process

A production process and modular technology, applied in the field of non-ferrous metal smelting, can solve the problems of increasing the cost of construction and maintenance, the lack of metal in the waste slag, and staying in semi-industrial tests, etc., to improve the operability and economy , Fuel adaptability, reducing the effect of heating and melting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiment:

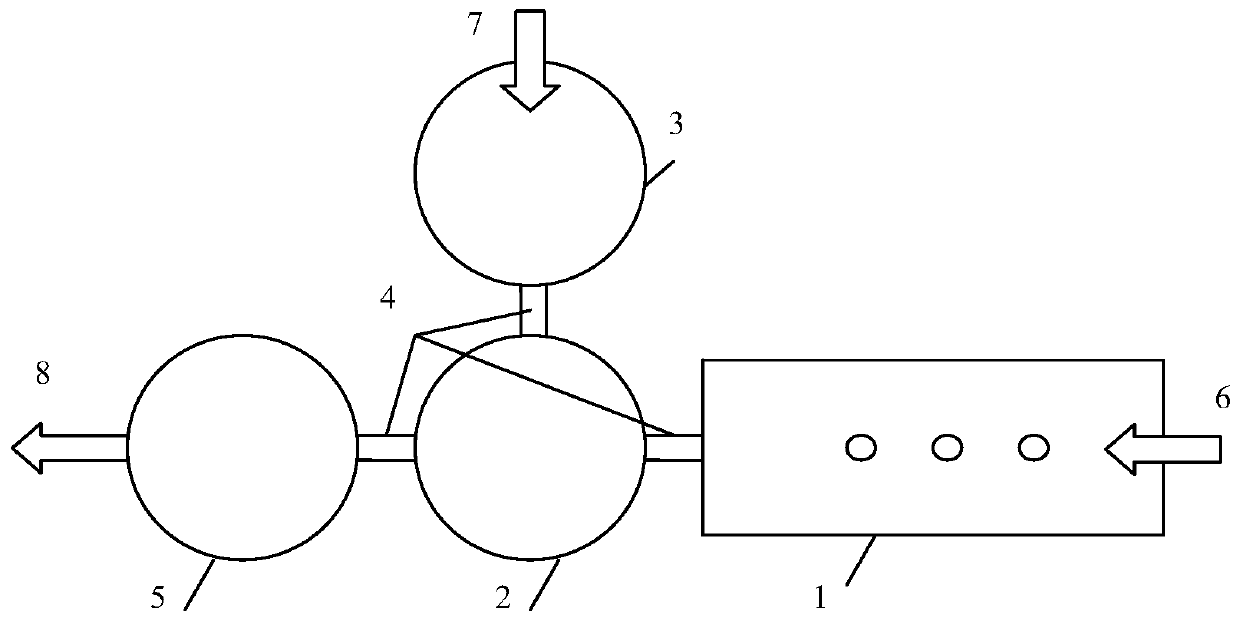

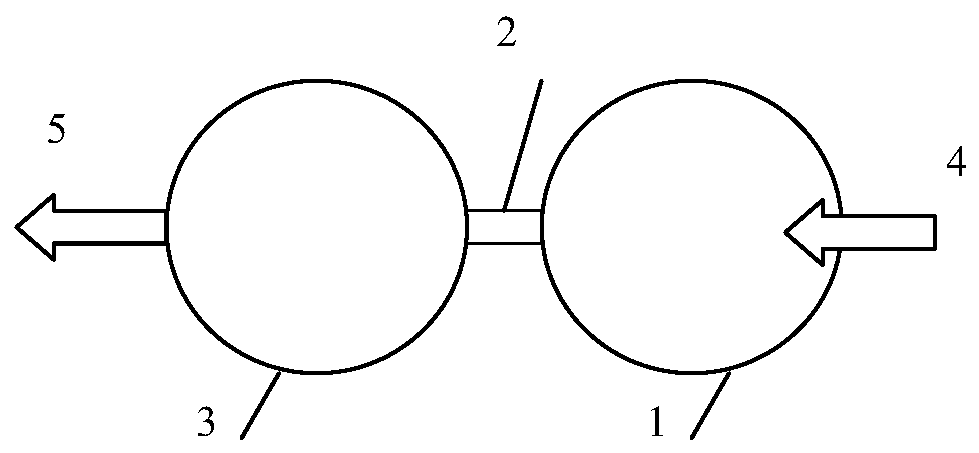

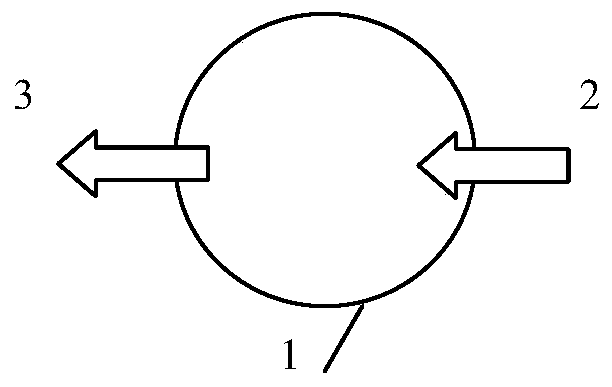

[0037] Due to the differences in the properties of materials from different sources, the differences in the physical and chemical properties of the valuable components contained, and the differences in the requirements of different metal compounds for the fuming process, the continuous fuming process of the present invention completes one or several functional melting pools through series and parallel combinations. Continuous fuming production; the specific combination plan should be determined according to the actual situation of the process, to realize continuous fuming production, complete the metallurgical process of fuming, enrichment and recovery of valuable metals in metallurgical materials, and finally achieve the optimal goal of economic and technical indicators . The following is a description of the combination methods proposed according to the specific site condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com