Ethanol fuel cell anode and preparation method thereof

A fuel cell and anode technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of accelerating the poisoning of noble metal catalysts, aggravating the failure of ethanol fuel cells, and expensive noble metals, so as to avoid carbon corrosion and adhesive aging, The effect of saving labor and material costs and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

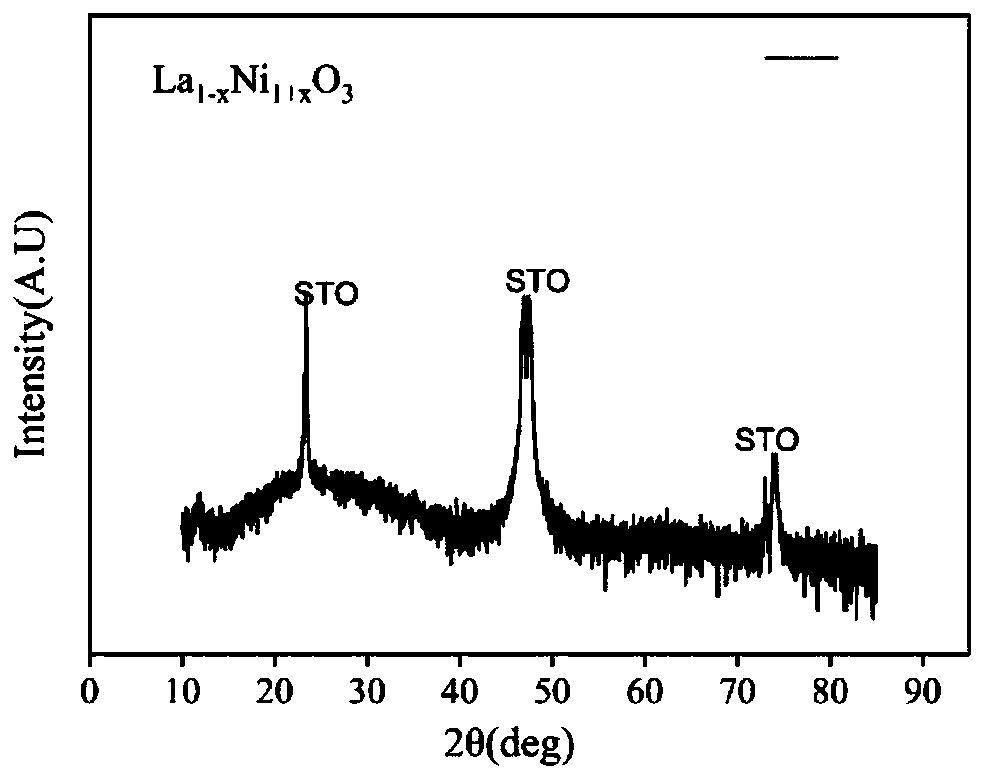

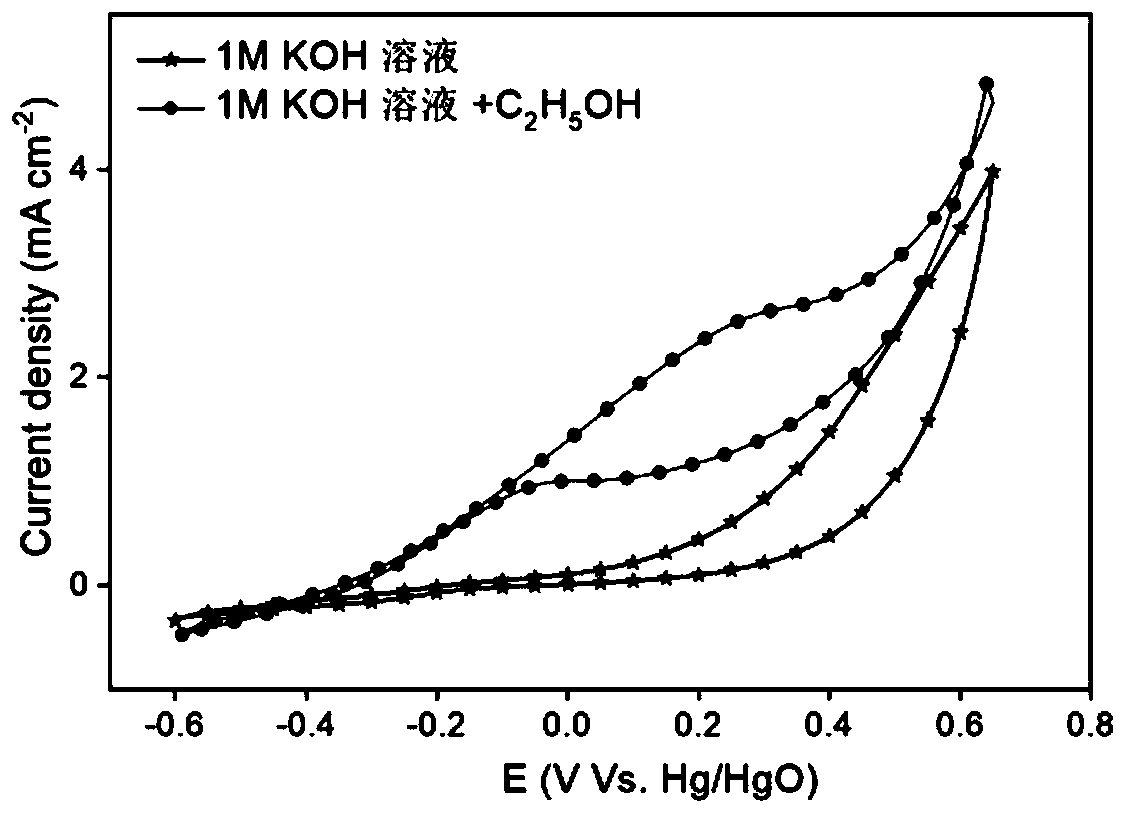

[0031] This embodiment provides a La 1-x Ni 1+x o 3 Ethanol fuel cell anode and preparation method of perovskite film-coated foamed copper; the specific process is:

[0032] A. Preparation

[0033] Step 1, pretreatment of the foamed copper substrate; cut the foamed copper with a length and width of 4cm, a thickness of 0.5mm, and a purity of 99.99%, ultrasonically wash in acetone for 8 hours to remove grease, and ultrasonically wash in 6% dilute hydrochloric acid for 10 minutes to remove copper on the surface Oxides, washed with high-purity deionized water, dried in vacuum and set aside;

[0034] Step 2, press La 1-x Ni 1+x o 3 Composition variable x = 1% batching, grinding for 1 hour, firing La 1-x Ni 1+x o 3 target;

[0035] Step 3, the copper foam prepared in step 1 is preheated at 200°C in situ, and La 1-x Ni 1+x o 3 The target is placed on the target platform for laser pre-cleaning for 3 minutes to remove surface impurities;

[0036] Step 4, set the target di...

Embodiment 2

[0045] This example is a La 1-x Ni 1+x o 3 Ethanol fuel cell anode and preparation method of perovskite film-coated foamed copper; the specific process is:

[0046] A. Preparation

[0047] Step 1, pretreatment of the foamed copper substrate; cut the foamed copper with a length and width of 4cm, a thickness of 0.5mm, and a purity of 99.99%, ultrasonically wash in acetone for 8 hours to remove grease, and ultrasonically wash in 6% dilute hydrochloric acid for 10 minutes to remove copper on the surface Oxides, washed with high-purity deionized water, dried in vacuum and set aside;

[0048] Step 2, press La 1-x Ni 1+x o 3 Composition variable x = 2% batching, grinding for 1 hour, firing La 1-x Ni 1+x o 3 target;

[0049] Step 3, the copper foam prepared in step 1 is preheated at 200°C in situ, and La 1-x Ni 1+x o 3 The target is placed on the target platform for laser pre-cleaning for 3 minutes to remove surface impurities;

[0050] Step 4, set the target distance to...

Embodiment 3

[0059] This example is a La 1-x Ni 1+x o 3 Ethanol fuel cell anode and preparation method of perovskite film-coated foamed copper; the specific process is:

[0060] A. Preparation

[0061] Step 1, pretreatment of foamed copper substrate; cut the foamed copper with a length and width of 5cm, a thickness of 0.5mm, and a purity of 99.99%, ultrasonically wash in acetone for 9 hours to remove grease, and ultrasonically wash in 6% dilute hydrochloric acid for 10 minutes to remove copper on the surface Oxides, washed with high-purity deionized water, dried in vacuum and set aside;

[0062] Step 2, press La 1-x Ni 1+x o 3 Component variable x = 5% batching, grinding for 1 hour, firing La 1-x Ni 1+x o 3 target;

[0063] Step 3, the copper foam prepared in step 1 is preheated at 200°C in situ, and La 1-x Ni 1+x o 3 The target is placed on the target platform for laser pre-cleaning for 3 minutes to remove surface impurities;

[0064] Step 4, set the target distance to 6cm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com