PP flow master batch

A technology of masterbatch and flow, which is applied in the field of masterbatch preparation technology, can solve the problems of toughness, wear resistance and other problems, and achieve the effect of improving toughness, enhancing toughness and tensile strength, and enhancing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

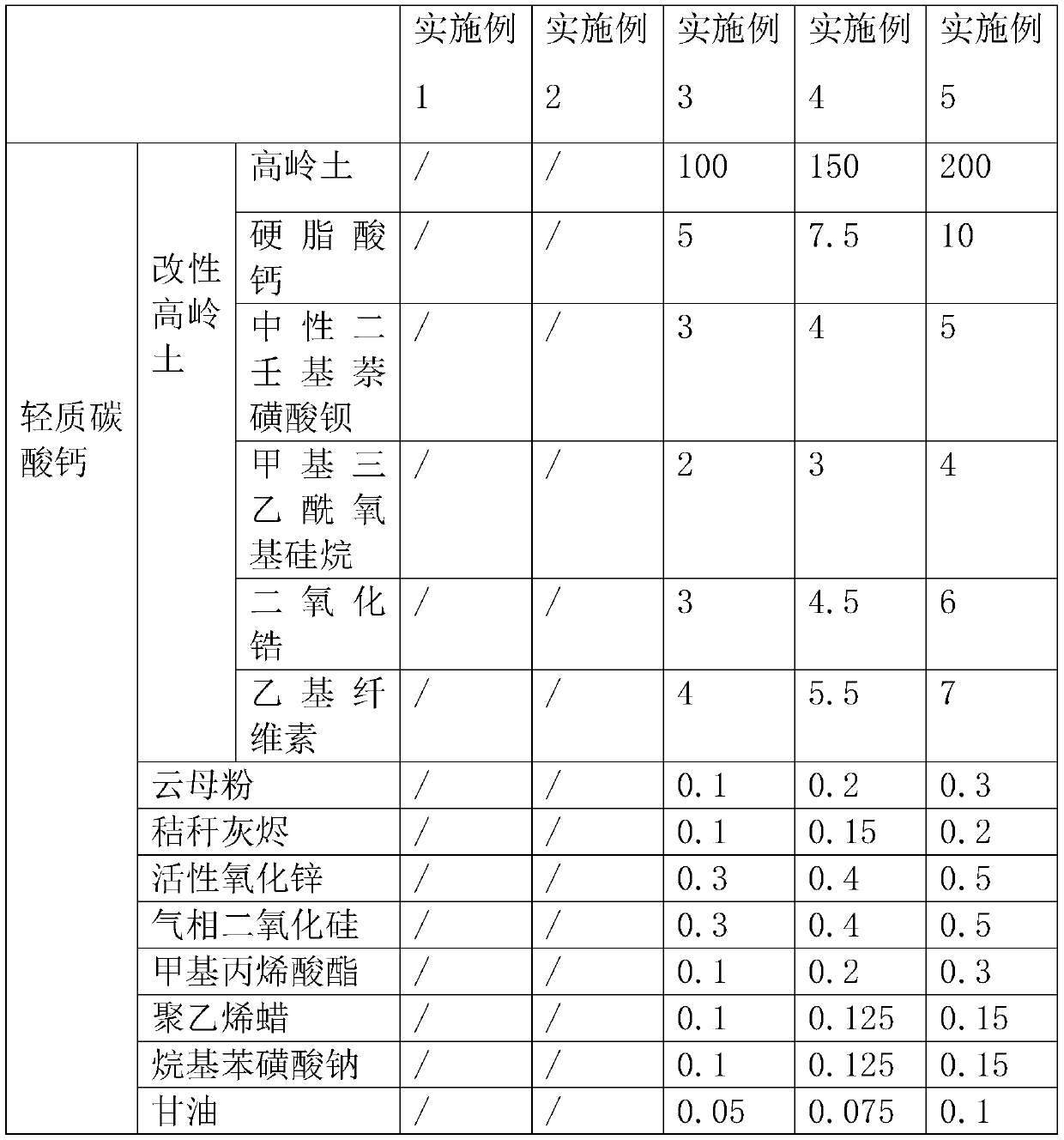

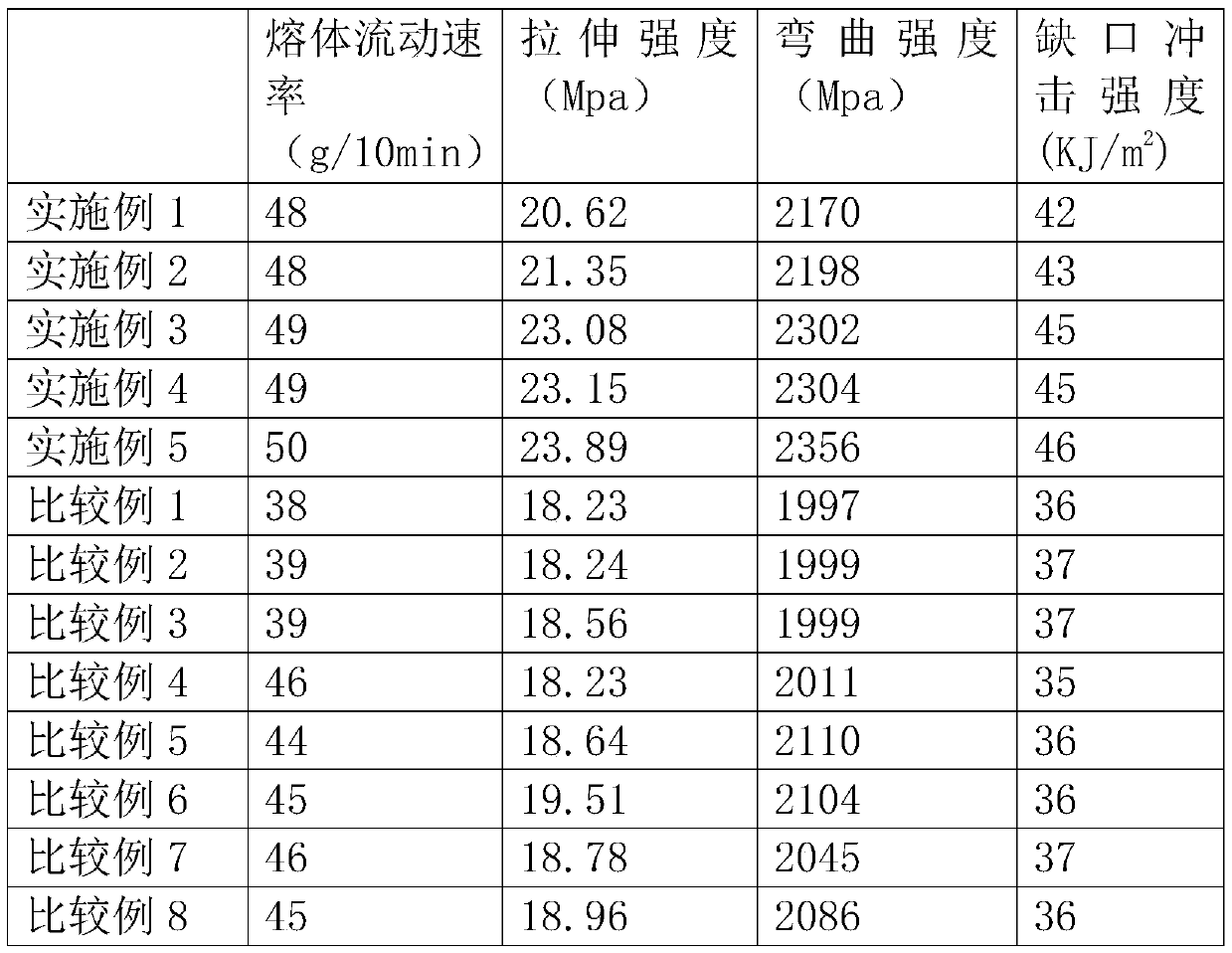

[0052] The components and parts by weight of PP flow masterbatch are shown in Table 1.

[0053] The components and parts by weight of light calcium carbonate in PP flow masterbatch are shown in Table 2.

[0054] S1. Weigh the corresponding number of polypropylene resin, initiator and light calcium carbonate and mix and stir for 10 minutes to prepare PP flow masterbatch raw material.

[0055] In this embodiment, the initiator is composed of di-tert-butyl peroxide and tert-butyl hydroperoxide 1:1.2, and di-tert-butyl peroxide adopts di-tert-butyl peroxide from Jiangsu Quanwei Chemical Co., Ltd.; tert-butyl Hydrogen peroxide adopts tert-butyl hydroperoxide from Jiangsu Quanwei Chemical Co., Ltd.

[0056] In this embodiment, the polypropylene resin is the polypropylene resin of Maoming Shihua Dongcheng Chemical Co., Ltd., the model is PP230, and the melt flow rate of the polypropylene resin is 19 g / 10 min.

[0057] Wherein, the light calcium carbonate in step S1 is modified calc...

Embodiment 2

[0069] The difference with embodiment 1 is:

[0070] The components and parts by weight of PP flow masterbatch are shown in Table 1.

[0071] The components and parts by weight of light calcium carbonate in PP flow masterbatch are shown in Table 2.

[0072] In this example, the initiator is composed of di-tert-butyl peroxide and tert-butyl hydroperoxide in a ratio of 1:1.3.

[0073] In this embodiment, the melt flow rate of the polypropylene resin used to prepare the PP flow masterbatch is 24g / 10min.

[0074] The modification method step of the modified calcium carbonate of step S1 is as follows:

[0075] a. Weigh light calcium carbonate in corresponding parts by weight, dry it until the moisture content is below 0.3% by weight, and add it into the reaction kettle.

[0076] b. Add kaolin, mica powder, straw ash, active zinc oxide, fumed silica, methacrylate, polyethylene wax, sodium alkylbenzene sulfonate, glycerol in corresponding parts by weight to the reactor, and heat u...

Embodiment 3

[0083] The difference with embodiment 1 is:

[0084] The components and parts by weight of PP flow masterbatch are shown in Table 1.

[0085] The components and parts by weight of light calcium carbonate in PP flow masterbatch are shown in Table 2.

[0086] In this example, the initiator is composed of di-tert-butyl peroxide and tert-butyl hydroperoxide in a ratio of 1:1.3.

[0087] In this embodiment, the melt flow rate of the polypropylene resin used to prepare the PP flow masterbatch is 27 g / 10 min.

[0088] The modification method step of the modified calcium carbonate of step S1 is as follows:

[0089] a. Weigh light calcium carbonate in corresponding parts by weight, dry it until the moisture content is below 0.3% by weight, and add it into the reaction kettle.

[0090] b. Add kaolin, mica powder, straw ash, active zinc oxide, fumed silica, methacrylate, polyethylene wax, sodium alkylbenzene sulfonate, glycerin to the reaction kettle, heat up to 120°C, keep stirring f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow velocity | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com