High-density epoxy resin blocking material

A technology of epoxy resin and plugging materials, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of low strength, achieve high strength, increase cross-linking density, and improve wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

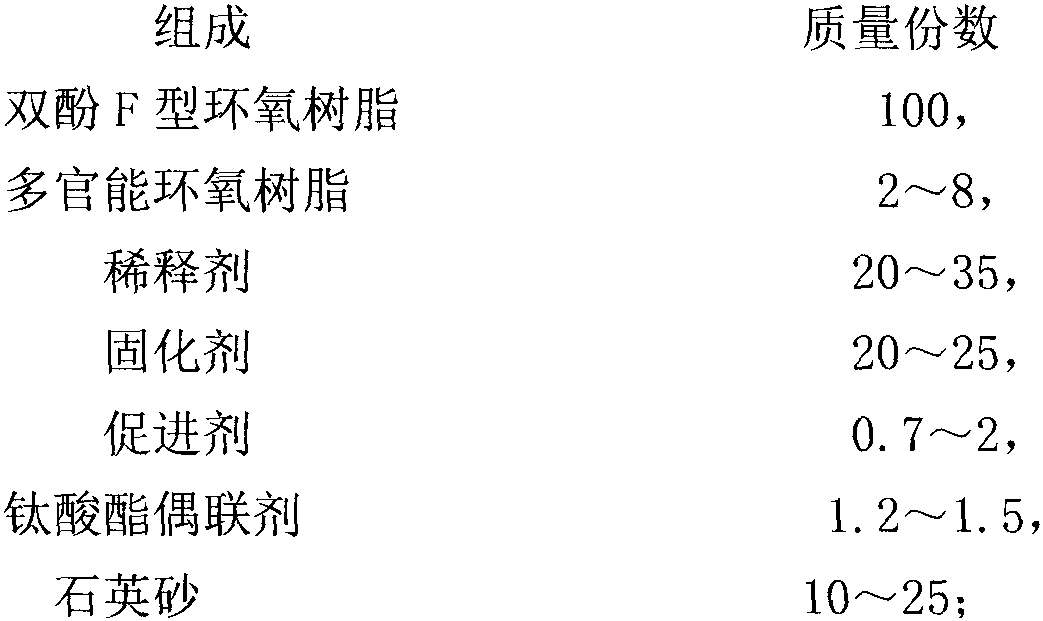

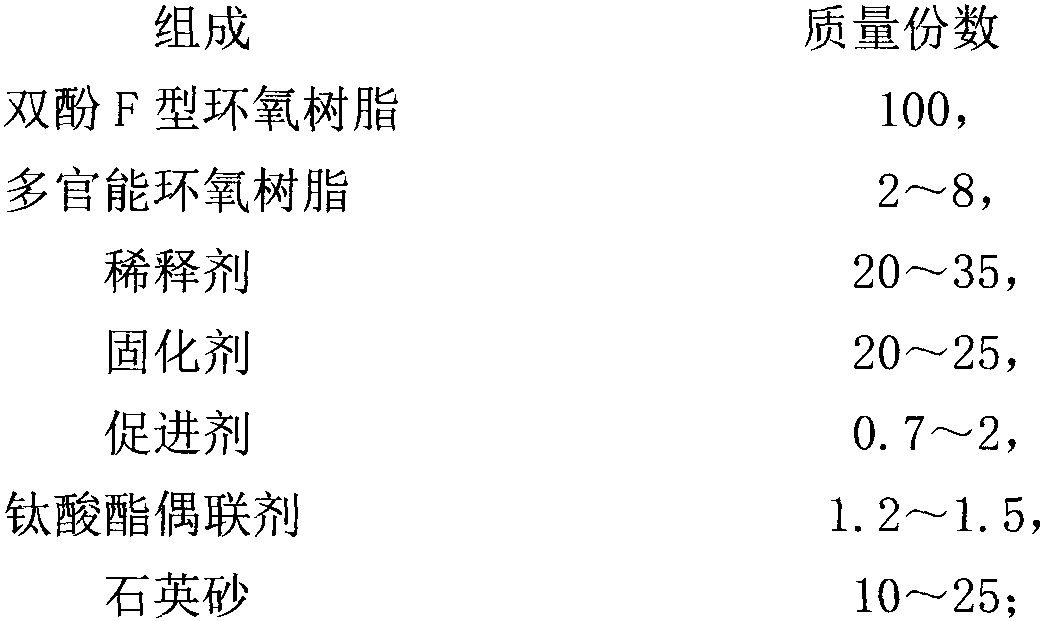

Method used

Image

Examples

Embodiment 1

[0023] Weigh 1.2 parts of isopropyl tris(dioctylpyrophosphate acyloxy) titanate coupling agent and 50ml of aqueous ethanol (1:9) into a three-necked flask, and stir rapidly at 3000rpm at 40°C. While stirring, slowly add 10 parts of coupling-treated quartz sand and stir for 30 minutes. After the stirring is completed, wash with distilled water and dry in an oven at 100°C for 3 hours before use.

[0024] At room temperature, 100 parts of epoxy resin YDF-165, 8 parts of tetraglycidyl ether tetraphenylethane, 10 parts of quartz sand after coupling treatment and 25 parts of 1,4-butanediol diglycidyl ether were added to Stir evenly in the mixing tank and let it stand for 5 minutes; add 20 parts of 4,4'-diaminodicyclohexylmethane and 1.0 part of 2,4,6-tris(dimethylaminomethyl)phenol into the mixing tank, stir evenly, Eliminate air bubbles in a vacuum drying oven, and then cast in a mold; solidify the cast material at 80°C for 24 hours.

[0025] Viscosity: The measurement method refe...

Embodiment 2

[0029] The implementation steps are the same as Example 1, except that: the isopropyl tris(dioctyl pyrophosphate acyloxy) titanate coupling agent is changed from 1.2 parts to 1.5 parts, the stirring time is changed from 30 min to 60 min, and the coupling treatment The final quartz sand is changed from 10 parts to 15 parts, tetraglycidyl ether base tetraphenylethane is replaced by triphenyl glycidyl ether base methane, and 2,4,6-tris(dimethylaminomethyl)phenol is changed from 1.0 parts becomes 1.3 parts.

[0030] Performance measurement: the method is the same as in Example 1.

Embodiment 3

[0032] The implementation steps are the same as Example 1, except that the stirring temperature is changed from 30°C to 60°C, the quartz sand after coupling treatment is changed from 10 parts to 20 parts, and 25 parts of 1,4-butanediol diglycidyl ether is replaced 32 parts of butyl glycidyl ether and 20 parts of 4,4'-diaminodicyclohexylmethane are replaced by 25 parts of cardanol-modified phenalkamine.

[0033] Performance measurement: the method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com