Rare earth element doped aluminum alloy conductor of circuit cable and manufacturing method

A technology of aluminum alloy wires and rare earth elements, which is applied in the direction of cable/conductor manufacturing, metal/alloy conductors, circuits, etc., can solve the problems of uncontrollable shape of cables, loss of electrical performance, and difficult temperature control, etc., and achieve repair of small defects, Improved electrical properties and less deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment is a rare earth element-doped aluminum alloy wire for a circuit cable, which is characterized in that the cable core material is composed of the following components in mass percentage: Cu 0.02-0.03%, Fe 0.2-0.5%, Si 0.2-0.3%, Ag 0.01~0.03%, Li0.02~0.03%, RE 0.2~0.3%, the rest is Al and unavoidable impurities, and the total content of impurities is less than 0.01%;

[0032] The composition of RE is: one or more of La, Pm, Eu and one or more of Gd, Lu, Sc;

[0033] The cable is made of 5-10 cable core materials with the same diameter, and the cable is hot-rolled twice.

Embodiment 2

[0035] This embodiment further defines that the cable core material is composed of the following components in mass percentage: Cu 0.02%, Fe 0.3%, Si 0.2%, Ag 0.02%, Li 0.03%, RE 0.3%, and the rest are Al and unavoidable impurities , wherein the total content of impurities is less than 0.01%;

[0036] The components of RE are: La, Pm, Eu, Gd, Lu, Sc; the content of each component in RE is the same.

[0037] The cable is made of 8 cable core materials with the same diameter twisted together.

Embodiment 3

[0039] This embodiment is the manufacturing method of the rare earth element-doped aluminum alloy wire of the described circuit cable, comprising the following steps:

[0040] Alloy preparation:

[0041] Melt aluminum-iron alloy, aluminum-copper alloy, aluminum-lithium alloy, aluminum-silver alloy, rare earth RE and silicon at 750-800 degrees Celsius, and fully stir to obtain a rare earth-doped aluminum alloy stock solution;

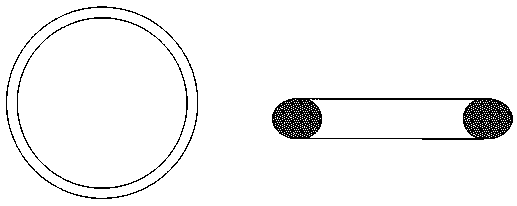

[0042] Rolling of aluminum rings:

[0043] Add the rare earth doped aluminum alloy stock solution to the continuous casting and rolling mill, roll the rare earth doped aluminum alloy stock solution into a spiral aluminum ring with a wire diameter of 5-10mm, the diameter of the aluminum ring is 0.8-1.5m, and cool to 100 degrees Celsius the following;

[0044] Wherein the wire diameter section of the aluminum ring is oval, and the curvature on the outside of the aluminum ring is smaller than the curvature on the inside of the aluminum ring;

[0045] Str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com