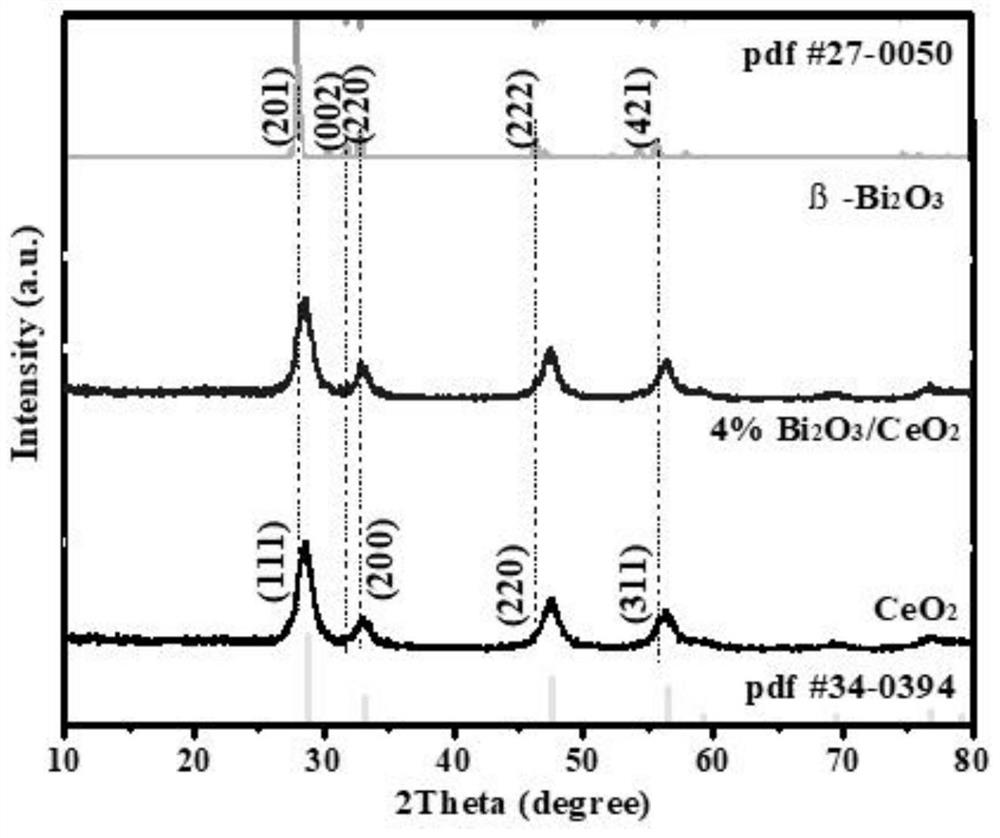

A z-mechanism rich in oxygen vacancies bi 2 o 3 @ceo 2 Photocatalyst and its preparation method and application

A technology of photocatalyst and oxygen vacancies, applied in the field of photocatalysis, can solve the problems of low utilization rate, high photocatalyst photogenerated electron-hole recombination rate, etc., and achieve the effect of fast degradation rate, high catalytic degradation activity, and easy operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

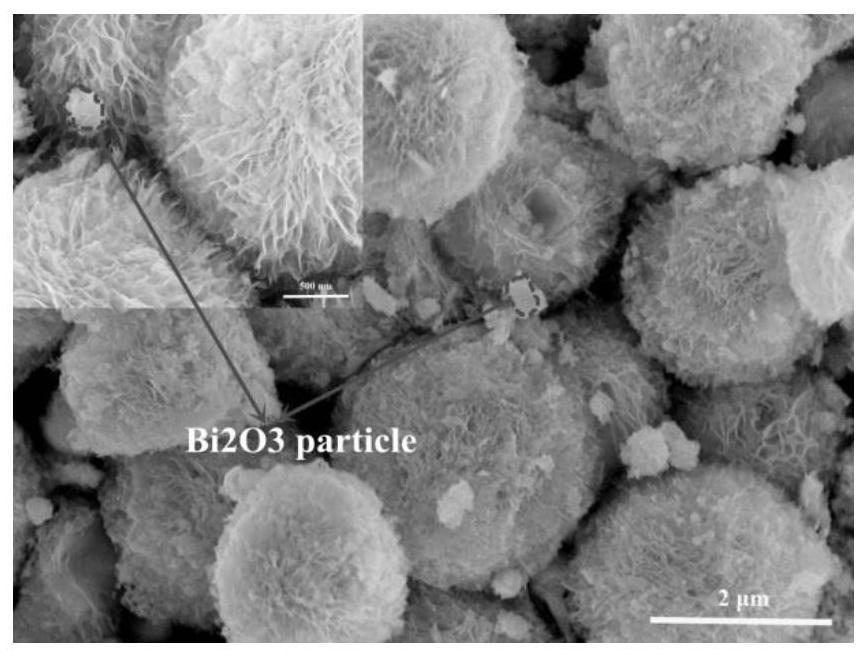

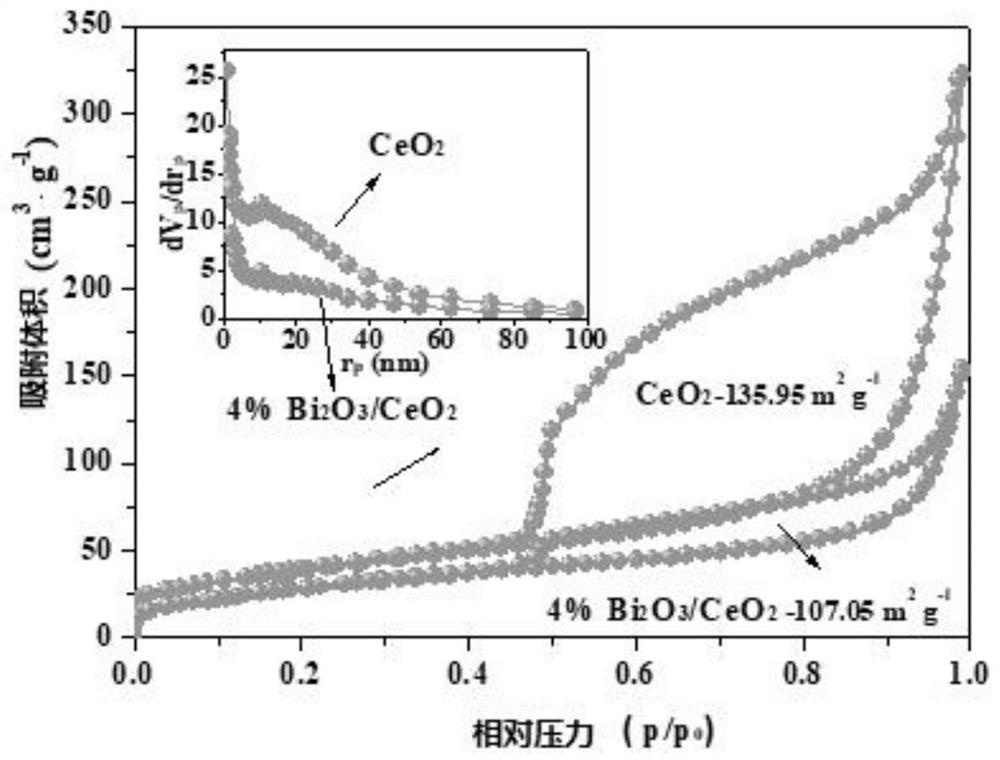

[0032] Oxygen vacancy-rich Z-mechanism Bi 2 o 3 @CeO 2 The preparation method of photocatalyst, it comprises the steps:

[0033] 1) Preparation of reaction solution

[0034] a. Dissolve 2 g of cerium nitrate hexahydrate in 60 mL of deionized water to form a uniform solution, then add 0.8 g of acrylamide and 1.8 g of glucose and stir for 20 minutes to prepare a cerium nitrate solution;

[0035] b. Bi(NO 3 ) 3 ·5H 2 O was dissolved in ethylene glycol solution and stirred for 20 minutes until the solution was uniform to prepare bismuth nitrate solution;

[0036] 2) Slowly drop the bismuth nitrate solution prepared in step 2) into the cerium nitrate solution prepared in step 1) according to the atomic ratio of Ce:Bi=1:0.04 and stir for 20 minutes, and use a volume concentration of 5% ammonia The pH of the aqueous solution was adjusted to 10, stirred for another 3 hours, and then transferred into a stainless steel reaction kettle for hydrothermal reaction at 180° C. for 72 h...

Embodiment 2

[0042] Different from Example 1, the oxygen-vacancy-rich Z-mechanism Bi prepared in this example 2 o 3 @CeO 2 The preparation method of photocatalyst comprises the following steps:

[0043] 1) Preparation of reaction solution

[0044] a. Dissolve 2.5 g of cerium nitrate hexahydrate in 50 mL of deionized water to form a uniform solution, then add 1 g of acrylamide and 1.6 g of glucose and stir for 28 minutes to prepare a cerium nitrate solution;

[0045] b. Bi(NO 3 ) 3 ·5H 2 O was dissolved in ethylene glycol solution and stirred for 26 minutes until the solution was uniform to prepare bismuth nitrate solution;

[0046] 2) Slowly drop the bismuth nitrate solution prepared in step 2) into the cerium nitrate solution prepared in step 1) according to the atomic ratio of Ce:Bi=1:0.04 and stir for 26 minutes, and use ammonia with a volume concentration of 7% The pH of the aqueous solution was adjusted to 10, and then stirred for 2.5 hours, then transferred into a stainless st...

Embodiment 3

[0051] Different from Example 1 and Example 2, the oxygen-vacancy-rich Z-mechanism Bi prepared in this example 2 o 3 @CeO 2 The preparation method of photocatalyst comprises the following steps:

[0052] 1) Preparation of reaction solution

[0053] a. Dissolve 3 g of cerium nitrate hexahydrate in 60 mL of deionized water to form a uniform solution, then add 1.2 g of acrylamide and 2 g of glucose and stir for 30 minutes to prepare a cerium nitrate solution;

[0054] b. Bi(NO 3 ) 3 ·5H 2 O was dissolved in ethylene glycol solution and stirred for 30 minutes until the solution was uniform to prepare bismuth nitrate solution;

[0055] 2) Slowly drop the bismuth nitrate solution prepared in step 2) into the cerium nitrate solution prepared in step 1) according to the atomic ratio of Ce:Bi=1:0.05 and stir for 30 minutes, and use ammonia with a volume concentration of 5.5%. The pH of the aqueous solution was adjusted to 11, stirred for another 3 hours, and then transferred int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com