Preparation method of p-aminophenetole

A technology for p-aminophenethyl ether and nitrobenzene, which is applied in the field of preparation of p-aminophenethyl ether, can solve the problems of high salt, high requirements, environmental pollution and the like, and achieves the effects of low temperature and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

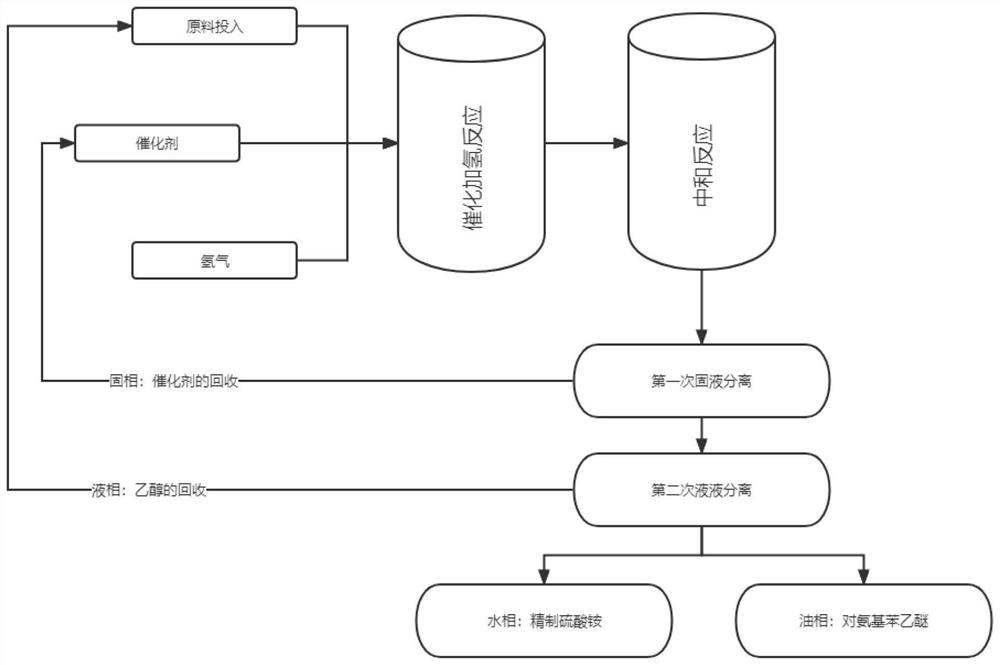

[0029] A kind of preparation method of p-aminophenyl ether, the main equipment used is: self-priming stirred kettle reactor (with shock function), enamel neutralization kettle, high-density barrel filter (with rotation function), solvent recovery device (with a certain negative pressure capacity), ammonium sulfate concentration and refining device, intermittent rectification tower.

[0030] The main steps are:

[0031]S1, catalytic hydrogenation reaction: in the self-priming stirred kettle reactor, the reaction conditions of adding ethanol and entering hydrogen, adding raw materials for mixing reaction, where the raw materials include a mixture of nitrobenzene and sulfuric acid; , the ratio of raw material nitrobenzene, sulfuric acid, ethanol mixture is 1:0.5:20 molar ratio, with Pt-C as the catalyst, the diameter of the catalyst particles is 0.01mm-10.0mm, the catalyst dosage is one thousandth of the amount of nitrobenzene, replace the air, pass into hydrogen, control the tempera...

Embodiment 2

[0043] A kind of preparation method of p-aminophenyl ether, the main equipment used is: self-priming stirred kettle reactor (with shock function), enamel neutralization kettle, high-density barrel filter (with rotation function), solvent recovery device (with a certain negative pressure capacity), ammonium sulfate concentration and refining device, intermittent rectification tower.

[0044] The main steps are:

[0045] S1, catalytic hydrogenation reaction: in the self-priming stirred kettle reactor, the reaction conditions of adding ethanol and entering hydrogen, adding raw materials for mixing reaction, where the raw materials include a mixture of nitrobenzene and sulfuric acid; The ratio of raw material nitrobenzene, sulfuric acid, ethanol mixture is 1:0.5:20 molar number ratio, with Pt-C as the catalyst, the diameter of the catalyst particles is 0.01mm-5mm, the catalyst dosage is one thousandth of the amount of nitrobenzene, replace the air, pass into hydrogen, control the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com