Preparation method of M phase vanadium dioxide powder, and temperature control layer

A technology of vanadium dioxide and vanadium pentoxide, applied in vanadium oxide, nanotechnology and other directions, can solve the problems of complex preparation and high energy consumption, and achieve the effects of small particles, low energy consumption and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

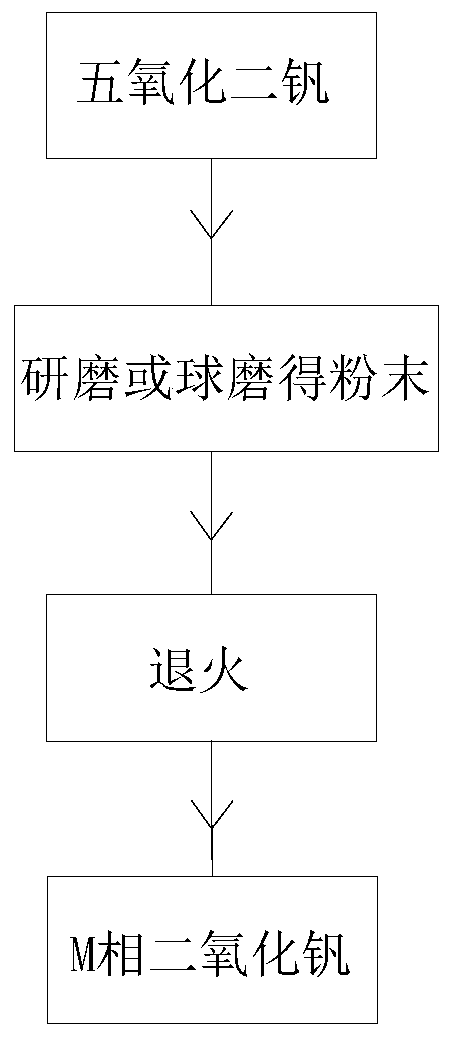

[0036] The embodiment of this application proposes a preparation method of M-phase vanadium dioxide powder, which includes: ball milling or grinding vanadium pentoxide to obtain vanadium pentoxide powder with a particle size of 50-300 nm, and under the protection of inert gas, the temperature Anneal the vanadium pentoxide powder at 500-700℃ for at least 30min. figure 1 It is a schematic flow chart of the preparation method of M phase vanadium dioxide powder provided in this application.

[0037] The vanadium pentoxide used in this application is obtained through purchase, and the purchased vanadium pentoxide is in powder form. However, according to experimental research, directly annealing the existing vanadium pentoxide below 700° C. cannot obtain M-phase vanadium dioxide. After research, the inventor of the present application found that the particle size of vanadium pentoxide affects the thermal decomposition of vanadium pentoxide, which in turn affects the preparation of M ph...

Embodiment 1

[0049] This embodiment provides a method for preparing M-phase vanadium dioxide powder, which includes the following steps:

[0050] 1) Take 4g vanadium pentoxide powder and disperse in 50ml methanol;

[0051] 2) Transfer the alcohol solvent to the ball mill tank, the ball mill speed is 400r / min, the ball mill is 60h to obtain the vanadium pentoxide slurry, the slurry is dried at 60℃, and the dried product is ground to obtain the powder again. The particle size of the powder About 300nm;

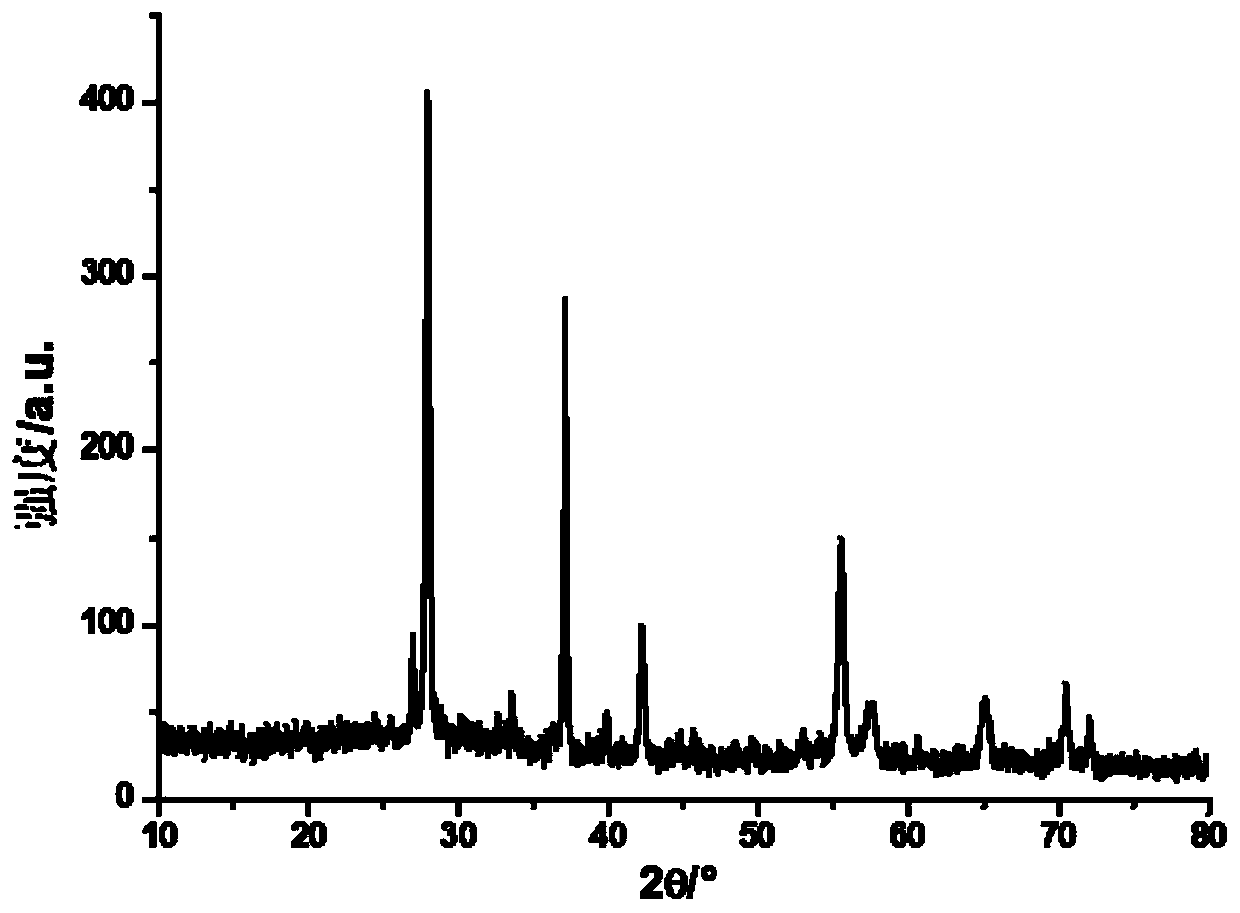

[0052] 3) The vanadium pentoxide powder obtained after ball milling is annealed at 600°C for 60 minutes under the protection of nitrogen to obtain the powder.

Embodiment 2

[0054] This embodiment provides a method for preparing M-phase vanadium dioxide powder, which includes the following steps:

[0055] 1) Take 9g vanadium pentoxide powder and disperse it in 100ml ethanol;

[0056] 2) Transfer the alcohol solvent to the ball mill tank, the ball mill speed is 700r / min, and the ball mill is 30h to obtain the vanadium pentoxide slurry. The slurry is dried at 70℃, and the dried product is ground to obtain the powder again. The particle size of the powder About 200nm;

[0057] 3) The vanadium pentoxide powder obtained after ball milling is annealed at 500°C for 90 minutes under the protection of argon gas to obtain M-phase vanadium dioxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com