Preparation method of aluminum-based high reflector for vacuum ultraviolet wave band

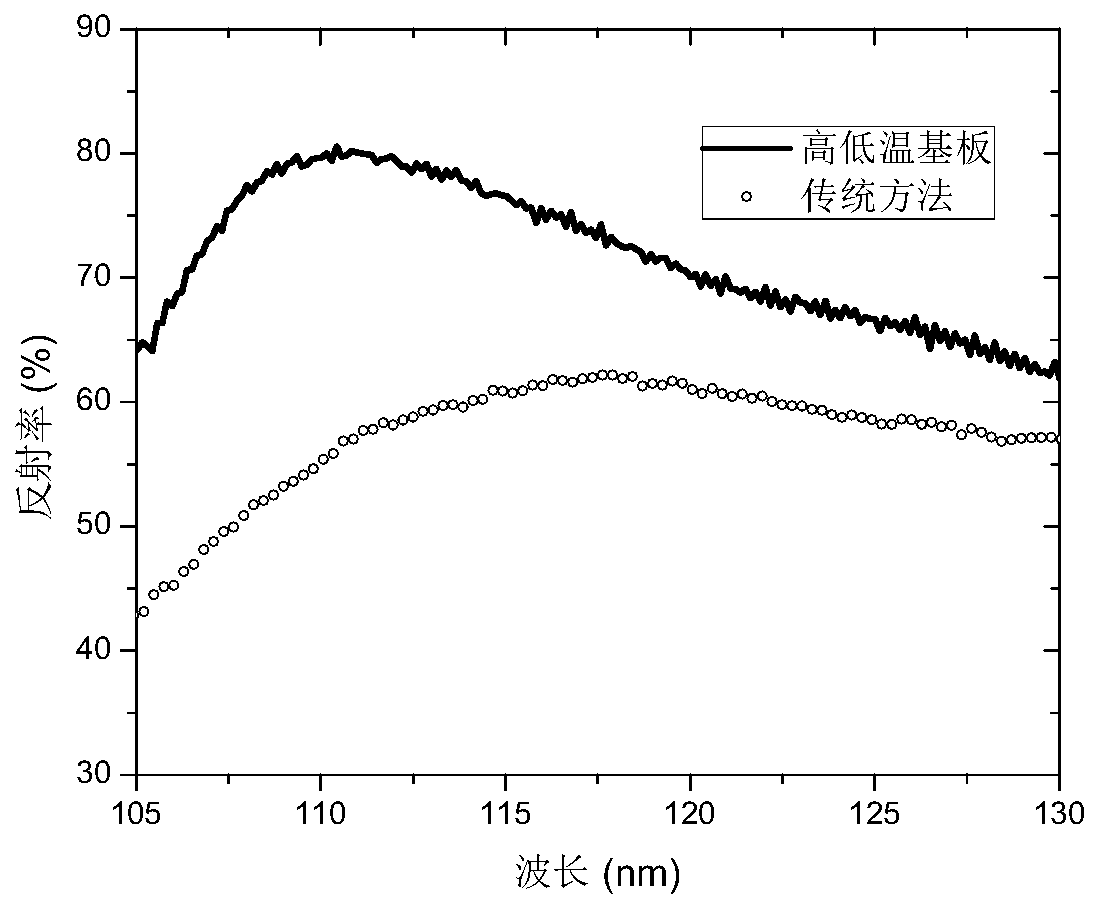

A technology of vacuum ultraviolet and high reflection mirror, which is applied in the direction of mirrors, optics, instruments, etc., can solve the problems such as the working environment that cannot be applied to the 105-115nm band, and achieve the effect of high repeatability and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

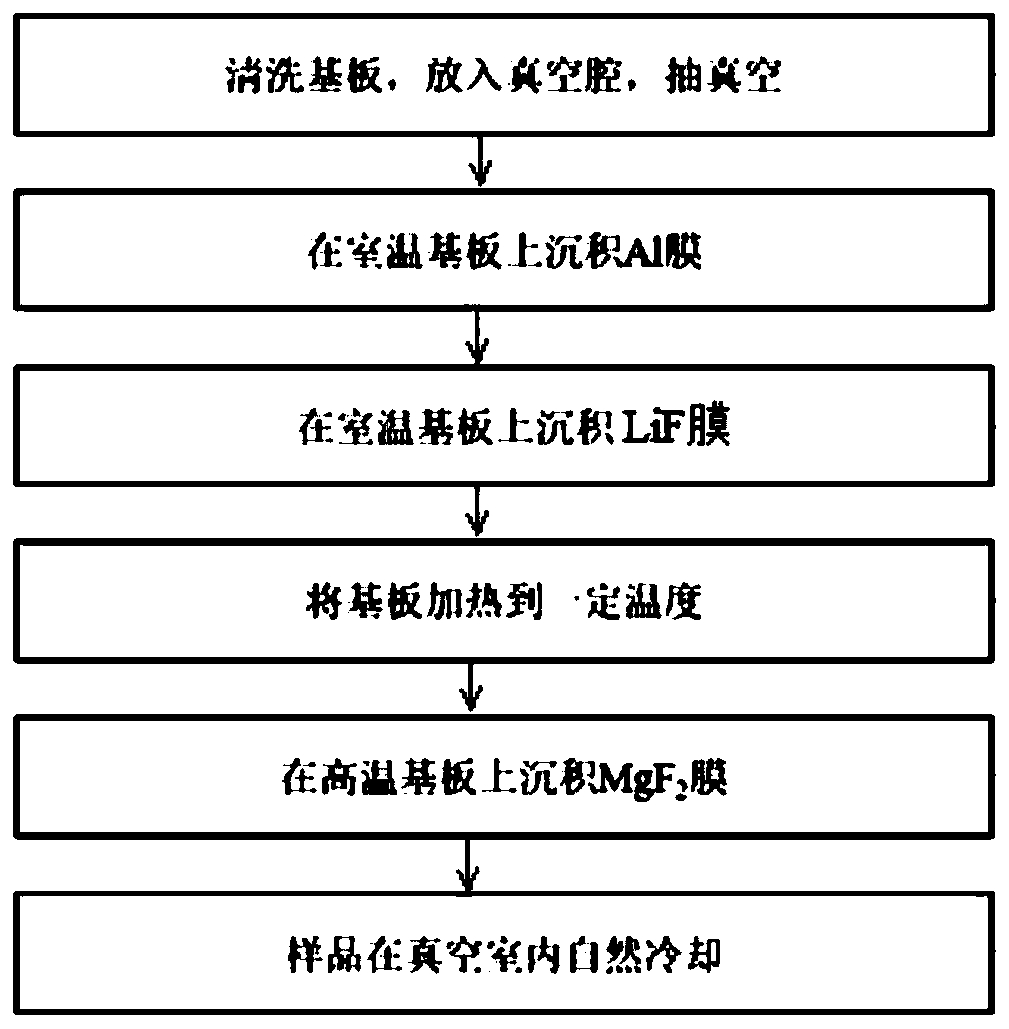

[0036] This embodiment provides a method for preparing an aluminum-based high-reflection mirror used in the vacuum ultraviolet band, such as figure 1 shown, including the following steps:

[0037] (1) Clean the substrate, dry it with nitrogen gas and install it on the sample holder of the coating machine. The surface roughness value Rq of the substrate is about 1.0 nm. Vacuumize the vacuum chamber of the coating machine to complete the vacuum preparation before coating;

[0038](2) Adjust the working current of the evaporation boat equipped with Al film material to 5A, and the working current of the evaporation boat equipped with LiF film material to 40A, perform preheating and degassing, and control the rotation of the sample holder equipped with the substrate at the same time. Adjust the working current of the evaporation boat equipped with Al film material to 40A. The deposition rate and film thickness are monitored by a crystal oscillator, and the thickness of the Al fil...

Embodiment 2

[0059] Compared with Example 1, most of them are the same, except in this example:

[0060] The thickness of the Al film is about 60nm, the target thickness of the LiF film is about 9nm, the MgF 2 The target thickness of the film is about 2 nm.

Embodiment 3

[0062] Compared with Example 1, most of them are the same, except in this example:

[0063] The thickness of the Al film is about 80nm, the target thickness of the LiF film is about 17nm, the MgF 2 The target thickness of the film is about 5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com