Method for preparing oxide eutectic ceramic through flash firing

A technology of eutectic ceramics and oxides, which is applied in the field of flash sintering to prepare oxide eutectic ceramics, can solve problems such as affecting high temperature creep resistance, and achieve the effect of small size and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

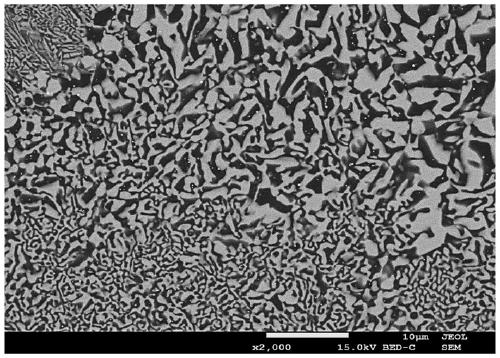

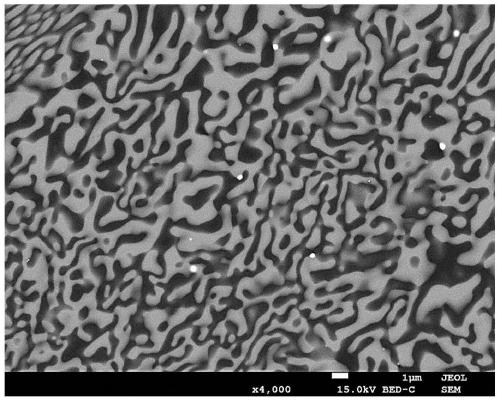

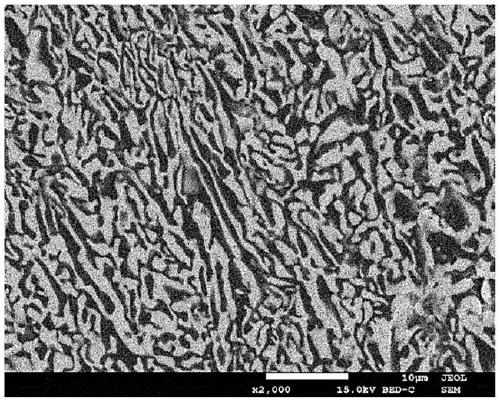

Image

Examples

Embodiment 1

[0035] The preparation method of aluminum oxide-yttrium aluminum garnet binary eutectic ceramics comprises the following steps:

[0036] Step 1: Mole ratio Al 2 o 3 :Y 2 o 3 = 80.8:19.2 Weigh the powder, a total of 20 g;

[0037]Step 2: Add 200 mL of deionized water and 2% polyethylene glycol-800 to the weighed powder, mix in a roller ball mill, the speed of the ball mill is 60 r / min, and the ball milling time is 20 h ;

[0038] Step 3: Carry out drying treatment to the obtained slurry, the drying temperature is 80 o C, the time is 12 h, and a uniformly mixed ceramic powder is obtained.

[0039] Step 4: adding PVA to the dried ceramic powder for granulation, the concentration of PVA is 3 wt%.

[0040] Step 5: The granulated powder is molded into a dog-bone-shaped sample with a pressure of 200 MPa and a hold pressure of 60 s. The sample is then placed in a cold isostatic press for secondary pressure at a pressure of 290 MPa.

[0041] Step 6: Place the resulting green b...

Embodiment 2

[0045] A preparation method of alumina-yttrium aluminum garnet binary eutectic ceramics, comprising the steps of:

[0046] Step 1: Mole ratio Al 2 o 3 :Y 2 o 3 = 80.8:19.2 Weigh the powder, a total of 20 g;

[0047] Step 2: Add 200 mL of deionized water and 2% polyethylene glycol-800 to the weighed powder, mix in a roller ball mill, the speed of the ball mill is 60 r / min, and the ball milling time is 20 h ;

[0048] Step 3: Carry out drying treatment to the obtained slurry, the drying temperature is 80 o C, the time is 12 h, and a uniformly mixed ceramic powder is obtained.

[0049] Step 4: adding PVA to the dried ceramic powder for granulation, the concentration of PVA is 3 wt%.

[0050] Step 5: The granulated powder is molded into a dog-bone-shaped sample with a pressure of 200 MPa and a hold pressure of 60 s. The sample is then placed in a cold isostatic press for secondary pressure at a pressure of 290 MPa.

[0051] Step 6: Place the resulting green body at 800 o...

Embodiment 3

[0055] A preparation method of alumina-yttrium aluminum garnet binary eutectic ceramics, comprising the steps of:

[0056] Step 1: Mole ratio Al 2 o 3 :Y 2 o 3 = 80.8:19.2 Weigh the powder, a total of 20 g;

[0057] Step 2: Add 200 mL of deionized water to the weighed powder, and polyethylene glycol-800 with a mass fraction of 2% as a surfactant, mix in a roller ball mill, and the speed of the ball mill is 60 r / min, Ball milling time 20 h;

[0058] Step 3: Carry out drying treatment to the obtained slurry, the drying temperature is 80 o C, the time is 12 h, and a uniformly mixed ceramic powder is obtained.

[0059] Step 4: adding PVA to the dried ceramic powder for granulation, the concentration of PVA is 3 wt%.

[0060] Step 5: The granulated powder is molded into a dog-bone-shaped sample with a pressure of 200 MPa and a hold pressure of 60 s. The sample is then placed in a cold isostatic press for secondary pressure at a pressure of 290 MPa.

[0061] Step 6: Place t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com