A method for compound antioxidant granulation

A composite antioxidant and granulation technology, applied in the chemical industry, can solve the problems of ineffectiveness, decomposition, and inability to achieve expected effects of composite antioxidants, achieve a safe and reliable production environment, reduce dust, and improve production efficiency and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

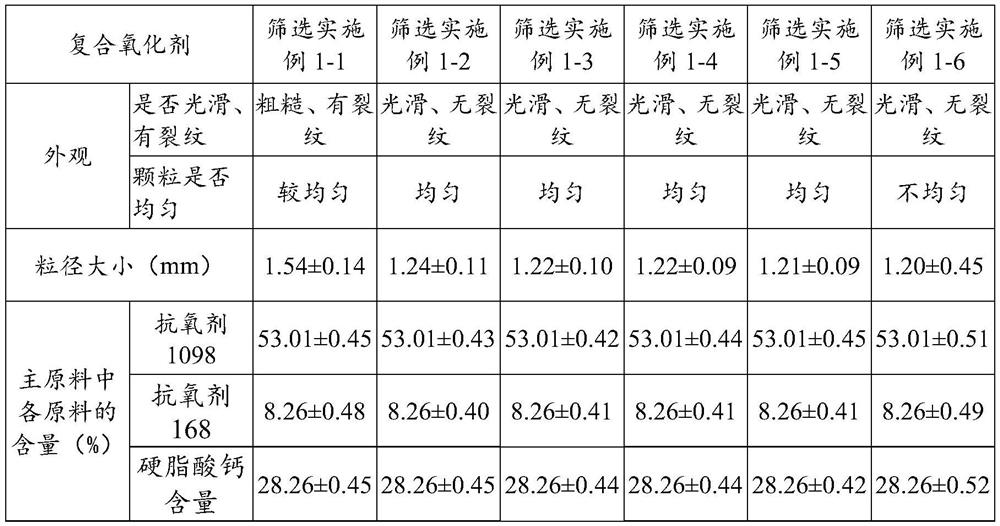

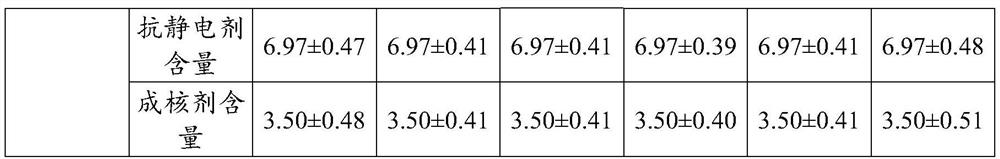

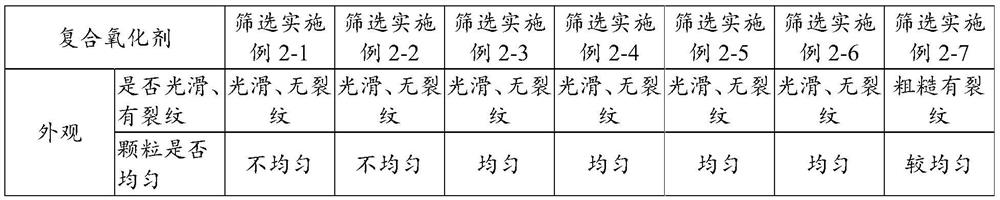

[0016] The mass ratio screening embodiment of screening embodiment 1 organic solvent and main raw material:

Embodiment 1-1

[0018] A method for granulating a composite antioxidant. The composite antioxidant is prepared from a main antioxidant, an auxiliary antioxidant, an acid absorbing agent, and an auxiliary agent as main raw materials, and the steps are as follows:

[0019] (1) In the stirred tank, add 58.45g (67.97ml) xylene, then add 22.13g antioxidant 1098, 3.45g antioxidant 168, 11.8g calcium stearate, 2.91g antistatic agent, 1.46g Stir the nucleating agent at a speed of 800-1200rpm until it is completely dissolved, stir and mix evenly, and the stirring time is 10-15min to obtain a liquid mixture;

[0020] (2) After mixing evenly, the liquid mixture in the above step (1) is filtered through a sieve with sieve holes of 20-50 μm to obtain the mixture liquid;

[0021] (3) The mixture liquid in the above step (2) is sprayed and granulated through the air-flow pressure spray granulation tower, and the spherical particles are obtained by spraying. ℃, feed rate is 15ml / min, air flow rate is 0.5m ...

Embodiment 1-2

[0023] A method for granulating a composite antioxidant. The composite antioxidant is prepared from a main antioxidant, an auxiliary antioxidant, an acid absorbing agent, and an auxiliary agent as main raw materials, and the steps are as follows:

[0024] (1) In the stirred tank, add 62.63g (72.83ml) xylene, then add 22.13g antioxidant 1098, 3.45g antioxidant 168, 11.8g calcium stearate, 2.91g antistatic agent, 1.46g Stir the nucleating agent at a speed of 800-1200rpm until it is completely dissolved, stir and mix evenly, and the stirring time is 10-15min to obtain a liquid mixture;

[0025] The step (2) and step (3) of this screening example are exactly the same as the step (2) and step (3) of the screening example 1-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com