Method for producing light olefins

A low-carbon olefin and regenerant technology, which is applied in the production of bulk chemicals, processing of hydrocarbon oil, and hydrocarbon cracking to produce hydrocarbons, etc., can solve the problems of low olefin yield, low coke yield, and high coke yield, and achieve olefin low yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

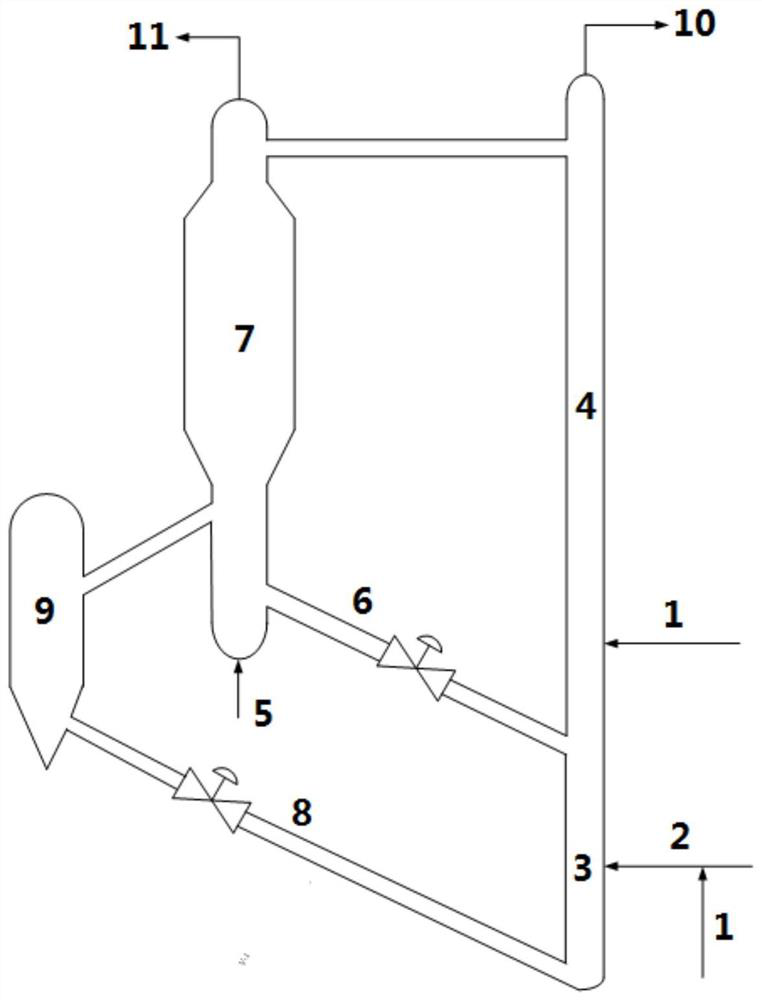

[0043] The raw material oil 2 and water vapor 1 are introduced into the first cracking reaction zone 3 containing the first contact agent through the pipeline for cracking reaction, and then the steam 1 and the stream in the first cracking reaction zone 3 are introduced into the second contacting The cracking reaction is carried out in the second cracking reaction zone 4 of the agent; then the stream after the cracking reaction obtained on the top or top of the second cracking reaction zone 4 is condensed to obtain gaseous substances, liquid substances and carbon deposition contact agents, and cracked products 10 out of the reaction system; the carbon-deposited catalyst is introduced into the regenerator 7 containing oxygen-containing gas 5 through the pipeline for coking treatment to obtain the regenerant, and the flue gas 11 produced in the regenerator 7 is discharged from the top of the regenerator 7 Draw out the reaction system; and introduce part of the regenerant directly...

Embodiment 1

[0055] According to this embodiment figure 1 The process route shown is carried out, specifically, in the present embodiment:

[0056] The raw oil and water vapor enter the first cracking reaction zone after preheating, the contact agent is MFC-2, and the process conditions are: reaction temperature 500°C, water-oil ratio 0.10, weight hourly space velocity 4h -1 , pressure 0.15MPa. The stream after the cracking reaction and part of the water vapor from the external pipeline enter the second cracking reaction zone. The process conditions are: reaction temperature 700°C, water-to-oil ratio 0.5, weight hourly space velocity 20h -1 , pressure 0.15MPa. The coke contact agent obtained after the contact cracking reaction enters the settler for stripping and then enters the regenerator for charring treatment. The process conditions are: the temperature in the dense-phase bed is 750 ° C, and the air is charred. Part of the regenerated agent after charring enters the second cracking ...

Embodiment 2

[0059] According to this embodiment figure 1 The process route shown is carried out, specifically, in the present embodiment:

[0060] The raw oil and water vapor enter the first cracking reaction zone after preheating, the contact agent is MFC-1, and the process conditions are: reaction temperature 540°C, water-oil ratio 0.20, weight hourly space velocity 12h -1 , pressure 0.28MPa. The stream after the cracking reaction and part of the water vapor from the external pipeline enter the second cracking reaction zone. The process conditions are: reaction temperature 620°C, water-to-oil ratio 0.9, weight hourly space velocity 40h -1 , pressure 0.28MPa. The coke contact agent obtained after the contact cracking reaction enters the settler for stripping and then enters the regenerator for charring treatment. The process conditions are: the temperature in the dense-phase bed is 700 ° C, and the air is charred. Part of the regenerated agent after charring enters the second cracking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com