Preparation method of three-dimensional graphene composite material, and application

A composite material and graphene technology, applied in the direction of graphene, analytical materials, material electrochemical variables, etc., can solve the problems of complex professional operations, time-consuming procedures, expensive instruments, etc., and achieve simple and convenient operation, good stability, and sensitivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

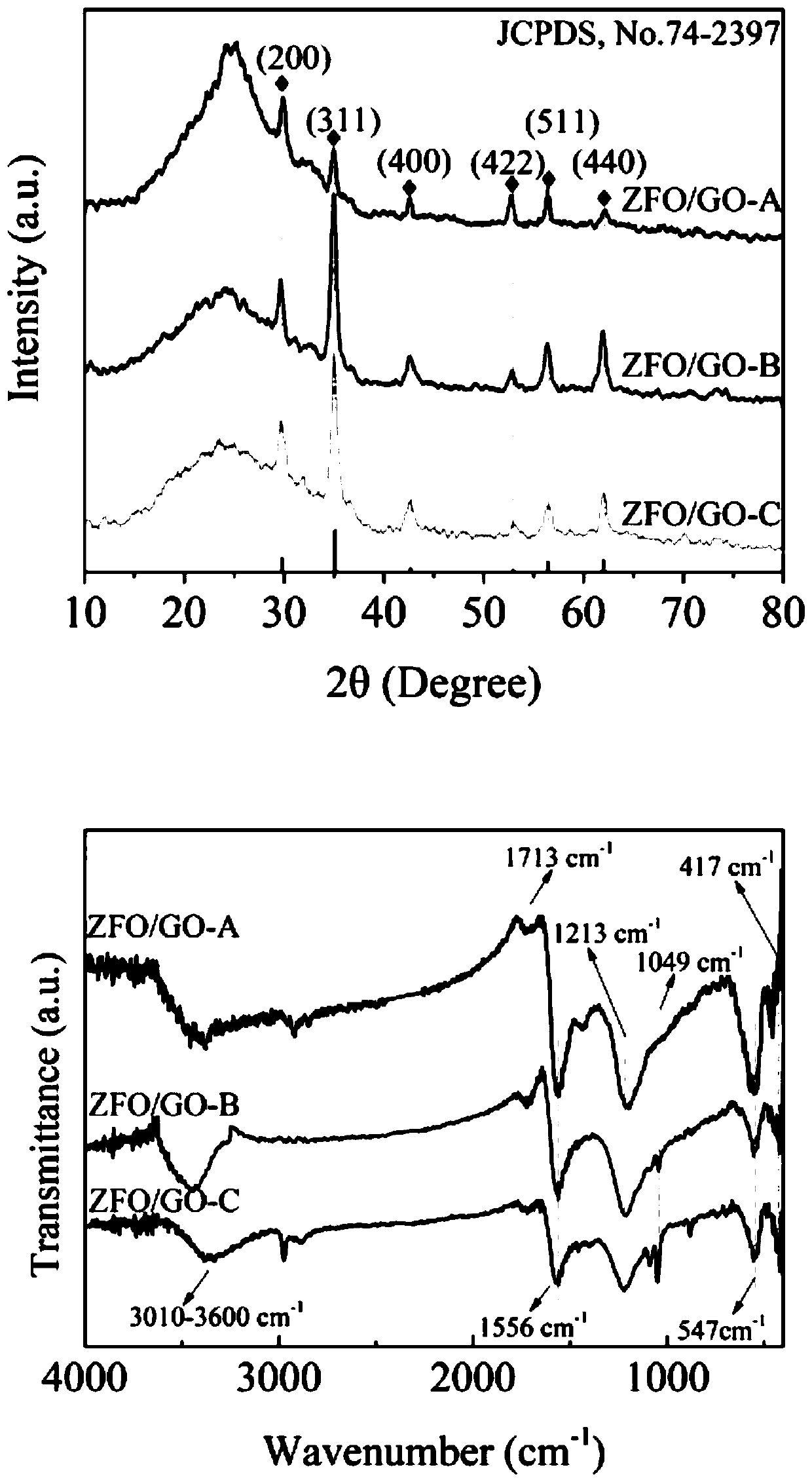

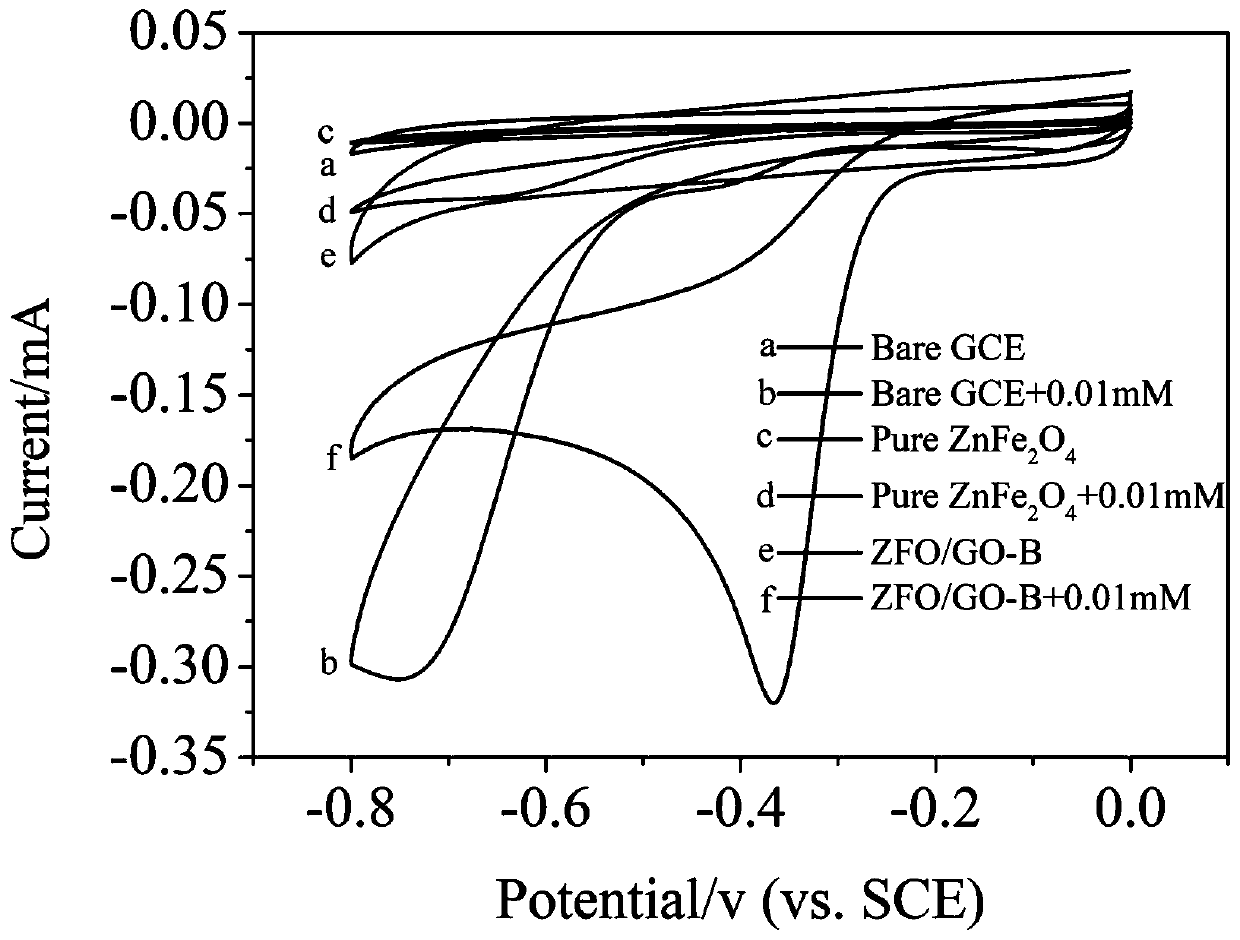

[0025] Dissolve 46 mg of tris(hydroxymethyl)aminomethane in 10 mL of benzyl alcohol, completely dissolve in an oil bath at 70°C, and then cool to room temperature; add 1 mmol (0.35317 g) of iron acetylacetonate and 0.5 mmol (0.1318 g) of zinc acetylacetonate as metal The precursor was stirred vigorously until it was completely dissolved; then the mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and placed in a 175°C oven to heat up for 48 hours to obtain a ZnFe-containing 2 o 4 Dark brown solution of nanoparticles; first wash with 4 times the volume of anhydrous ether, then wash 3 times with a mixed solution of ethanol and anhydrous ether, the volume ratio of ethanol to anhydrous ether = 1:1, centrifuge, and then the wet The precipitate was dispersed in ethanol and sonicated until a stable ZnFe 2 o 4 Nanoparticle dispersion 40mg / mL; take 15mL 4mg / mL graphene solution and add 0.5mL ZnFe 2 o 4 The nanoparticle dispersion was ultras...

Embodiment 2

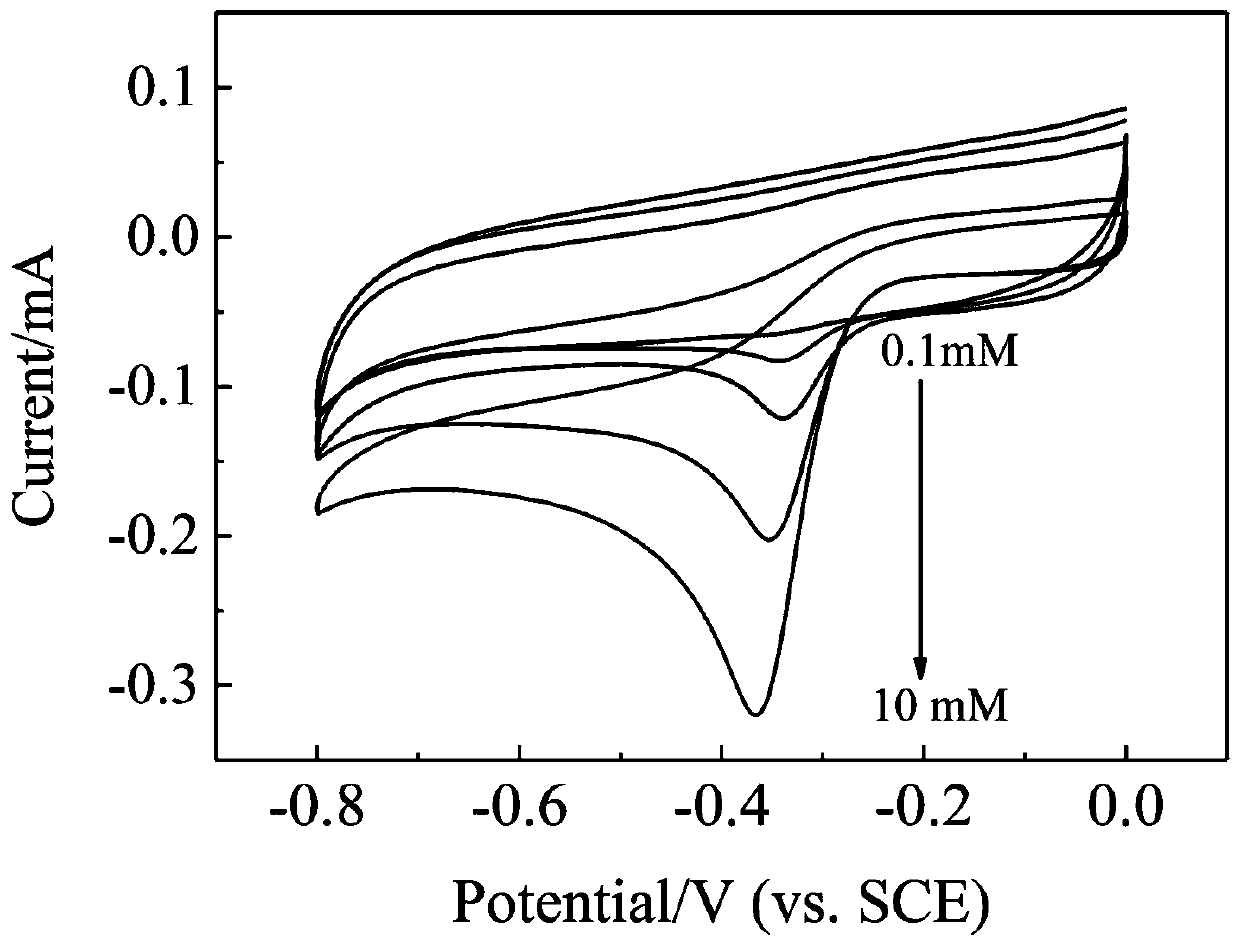

[0027] Dissolve 46 mg of tris(hydroxymethyl)aminomethane in 10 mL of benzyl alcohol, completely dissolve in an oil bath at 70°C, and then cool to room temperature; add 1 mmol (0.35317 g) of iron acetylacetonate and 0.5 mmol (0.1318 g) of zinc acetylacetonate as metal The precursor was stirred vigorously until it was completely dissolved; then the mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and placed in a 180°C oven to heat up for 48 hours to obtain a ZnFe-containing 2 o 4 The dark brown solution of nanoparticles; first wash with 4 times the volume of anhydrous ether, then wash 3 times with a mixed solution of ethanol and anhydrous ether, the volume ratio of ethanol to anhydrous ether=1:2, centrifuge, and then the wet The precipitate was dispersed in ethanol and sonicated until a stable ZnFe 2 o 4 Nanoparticle dispersion 40mg / mL; take 15mL 4mg / mL graphene solution and add 1mL ZnFe 2 o 4 The nanoparticle dispersion was ultras...

Embodiment 3

[0029] Dissolve 46 mg of tris(hydroxymethyl)aminomethane in 10 mL of benzyl alcohol, completely dissolve in an oil bath at 70°C, and then cool to room temperature; add 1 mmol (0.35317 g) of iron acetylacetonate and 0.5 mmol (0.1318 g) of zinc acetylacetonate as metal The precursor was stirred vigorously until it was completely dissolved; then the mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and placed in a 180°C oven to heat up for 36 hours to obtain a ZnFe-containing 2 o 4 The dark brown solution of nanoparticles; first wash with 4 times the volume of anhydrous ether, then wash 3 times with a mixed solution of ethanol and anhydrous ether, the volume ratio of ethanol to anhydrous ether=1:2, centrifuge, and then the wet The precipitate was dispersed in ethanol and sonicated until a stable ZnFe 2 o 4Nanoparticle dispersion 40mg / mL; take 15mL 4mg / mL graphene solution and add 1.5mL ZnFe 2 o 4 The nanoparticle dispersion was ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com