MOSFET and method for fabricating same

An n-type and p-type technology, applied in the field of device manufacturing, can solve the problems of large switching loss and large on-resistance, and achieve the effects of high applicable voltage, low power consumption, and low energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

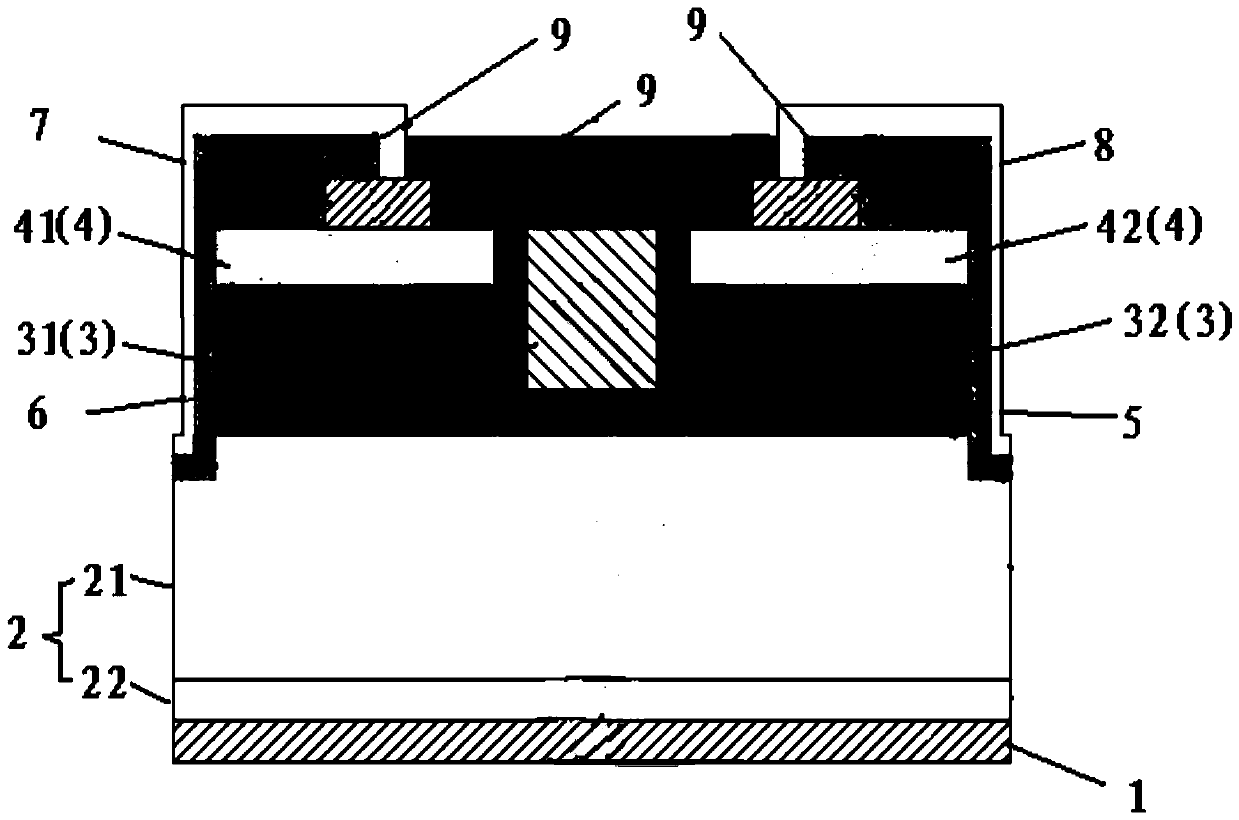

[0061] Another aspect of the present invention provides a method for preparing the above-mentioned MOSFET tube. combine Figure 1-3 , the preparation side of described MOSFET tube comprises the steps:

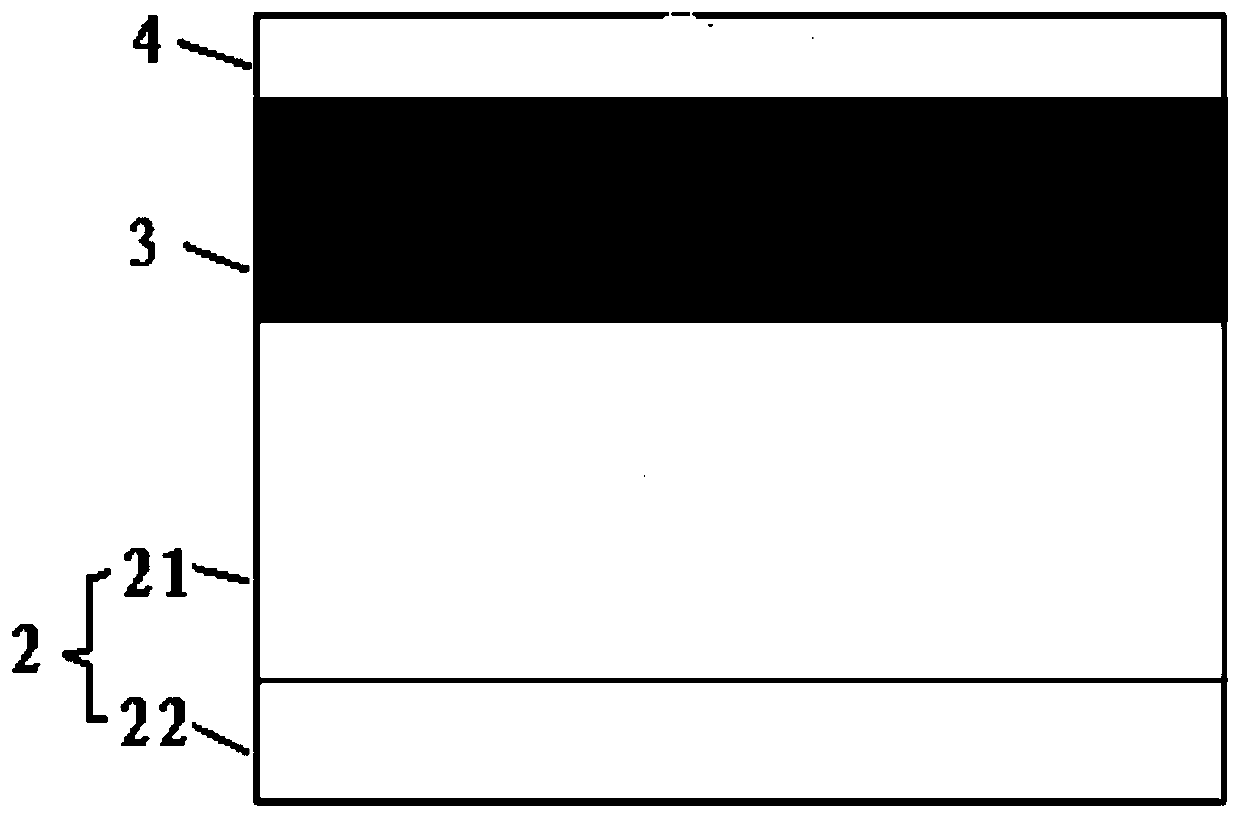

[0062] S01: along the direction extending outward from one surface of the substrate 1, the first n-type Si-doped GaN layer 22, the device drift layer 21, the p-type doped GaN layer 3, the second n-type Si-doped GaN layer 3, and the second Type Si-doped GaN layer 4; formed as figure 2 The layer structure shown.

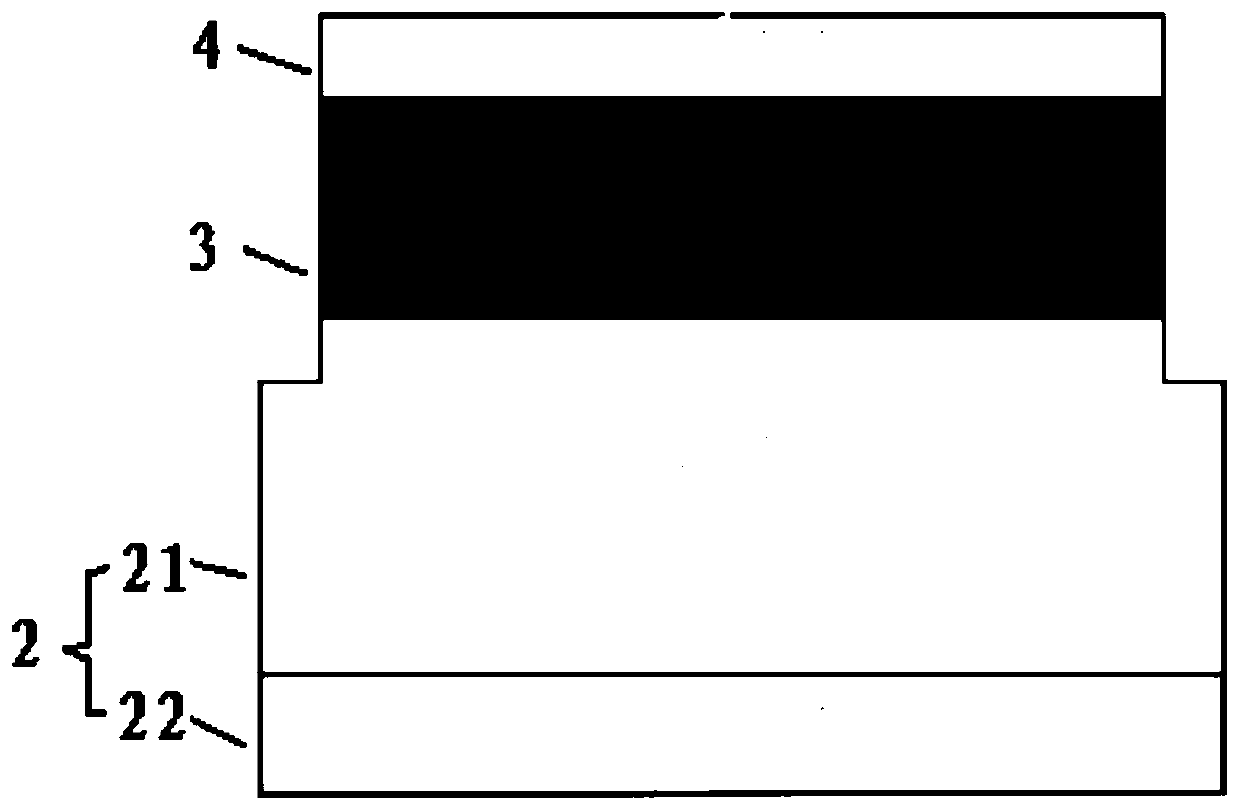

[0063] S02: Etching the edges of the device drift layer 21, the p-type doped GaN layer 3, and the second n-type Si-doped GaN layer 4 to form image 3 The MESA structure shown;

[0064] S03: Etching the middle sections of the p-type doped GaN layer 3 and the second n-type Si-doped GaN layer 4 to form trenches, the trenches penetrating to the surface of the device drift layer 21;

[0065] S04: Depositing a growth gate insulating layer 5 on the inner wall of the tren...

Embodiment 1

[0079] This implementation provides a MOSFET tube, including:

[0080] GaN substrate;

[0081] Substrate, n+-type Si-doped GaN layer thickness 1 μm and lightly Si-doped n-type Si-doped GaN thickness 6 μm;

[0082] The thickness of the P-type Mg-doped GaN layer is 0.3 μm;

[0083] The thickness of the n+ type Si-doped GaN layer is 0.2 μm;

[0084] The thickness of the AlSiO gate insulating layer is 50nm;

[0085] Ti(15nm) / Au(125nm) metal gate;

[0086] Ti(10nm) / Al(240nm) source and Al(250nm) drain;

[0087] SOG field plate dielectric layer;

[0088] This embodiment also provides a preparation method for the MOSFET tube, including:

[0089] Using molecular beam epitaxy (MBE), sequentially grow n+-type Si-doped GaN layers, lightly Si-doped n-type Si-doped GaN layers, p-type Mg-doped GaN layers, n+-type Si-doped GaN layers, and n+-type Si-doped GaN layers on GaN substrates. GaN layer;

[0090] Subsequently, through Cl 2 / SiCl 4 Dry etching on the above layer structure to...

Embodiment 2

[0098] This implementation provides a MOSFET tube, including:

[0099] SiC substrate;

[0100] Substrate, n+-type Si-doped GaN layer thickness 0.4 μm and lightly Si-doped n-type Si-doped GaN thickness 3 μm;

[0101] The thickness of the P-type Mg-doped GaN layer is 0.1 μm;

[0102] The thickness of the n+ type Si-doped GaN layer is 0.1 μm;

[0103] The thickness of the Al2O3 gate insulating layer is 40nm;

[0104] Ti(15nm) / Au(125nm) metal gate;

[0105] Ti(10nm) / Al(240nm) source and Al(250nm) drain;

[0106] SOG field plate dielectric layer;

[0107] This embodiment also provides a preparation method for the MOSFET tube, including:

[0108] Using organic chemical vapor deposition (MOCVD) to sequentially grow n+-type Si-doped GaN layers, lightly Si-doped n-type Si-doped GaN layers, P-type Mg-doped GaN layers, n+-type Si-doped GaN layers, and n+-type Si-doped GaN layers on GaN substrates. Doped GaN layer;

[0109] Subsequently, through Cl 2 / SiCl 4 Dry etching on the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com