Composite diaphragm comprising PVDF coating with lamellar structure and preparation method thereof, and application of composite diaphragm comprising PVDF coating with lamellar structure

A technology of composite diaphragm and sheet structure, which is applied in the direction of structural parts, electrical components, electrochemical generators, etc., can solve the problems of affecting the air permeability of composite diaphragms, affecting the transmission performance of lithium ions, and increasing the internal resistance of lithium-ion batteries. Facilitating transfer, ease of implementation, improved cycling and rate performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] [Preparation Method of Composite Separator]

[0059] As mentioned above, the present invention also provides a preparation method of the above-mentioned composite diaphragm, said method comprising the steps of:

[0060] 1) Disperse and swell PVDF powder and / or emulsion (a1) in a mixed aqueous solution of a dispersant and a plasticizer to prepare an aqueous dispersion containing PVDF powder and / or emulsion swollen by a plasticizer;

[0061] 2) The aqueous dispersion of step 1) is coated on one or both sides of the porous base film containing holes, and the PVDF powder and / or emulsion swelled by the plasticizer are softened under the action of gravity on the porous base due to plasticization and softening. The surface of the membrane becomes a sheet structure; a PVDF coating containing a sheet structure is formed during the drying process, that is, the composite diaphragm is prepared.

[0062] In a solution of the present invention, said step 1) includes the following st...

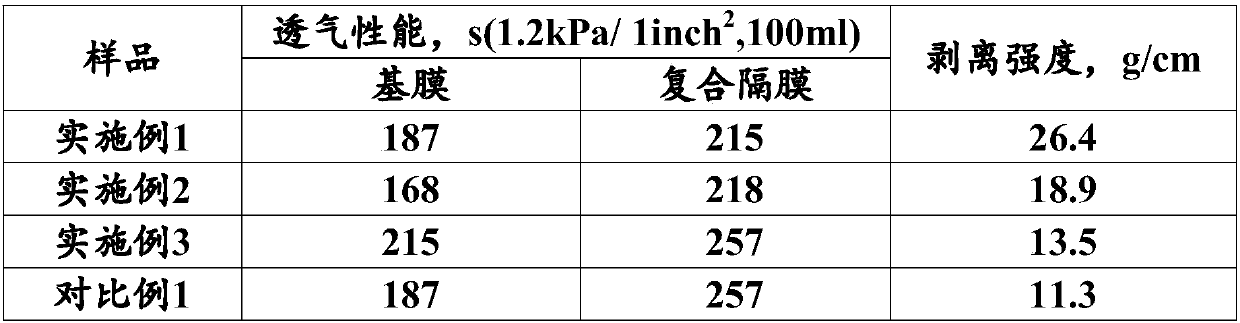

Embodiment 1

[0084]1) Preparation of aqueous dispersion containing PVDF powder and / or emulsion swollen by plasticizer: stir and disperse the dispersant sodium polymethacrylate and plasticizer N-methylpyrrolidone with water, then add PVDF powder and / or the emulsion (a1) to disperse and fully swell, and then add a binder to prepare an aqueous dispersion containing PVDF powder and / or emulsion swollen by a plasticizer. Wherein, the mass percentage of water is 83wt%; the mass percentage of dispersant is 0.5wt%; the mass percentage of plasticizer is 1.5wt%; the mass percentage of PVDF powder and / or emulsion (a1) is 10wt%; the mass percentage of the binder is 5wt%.

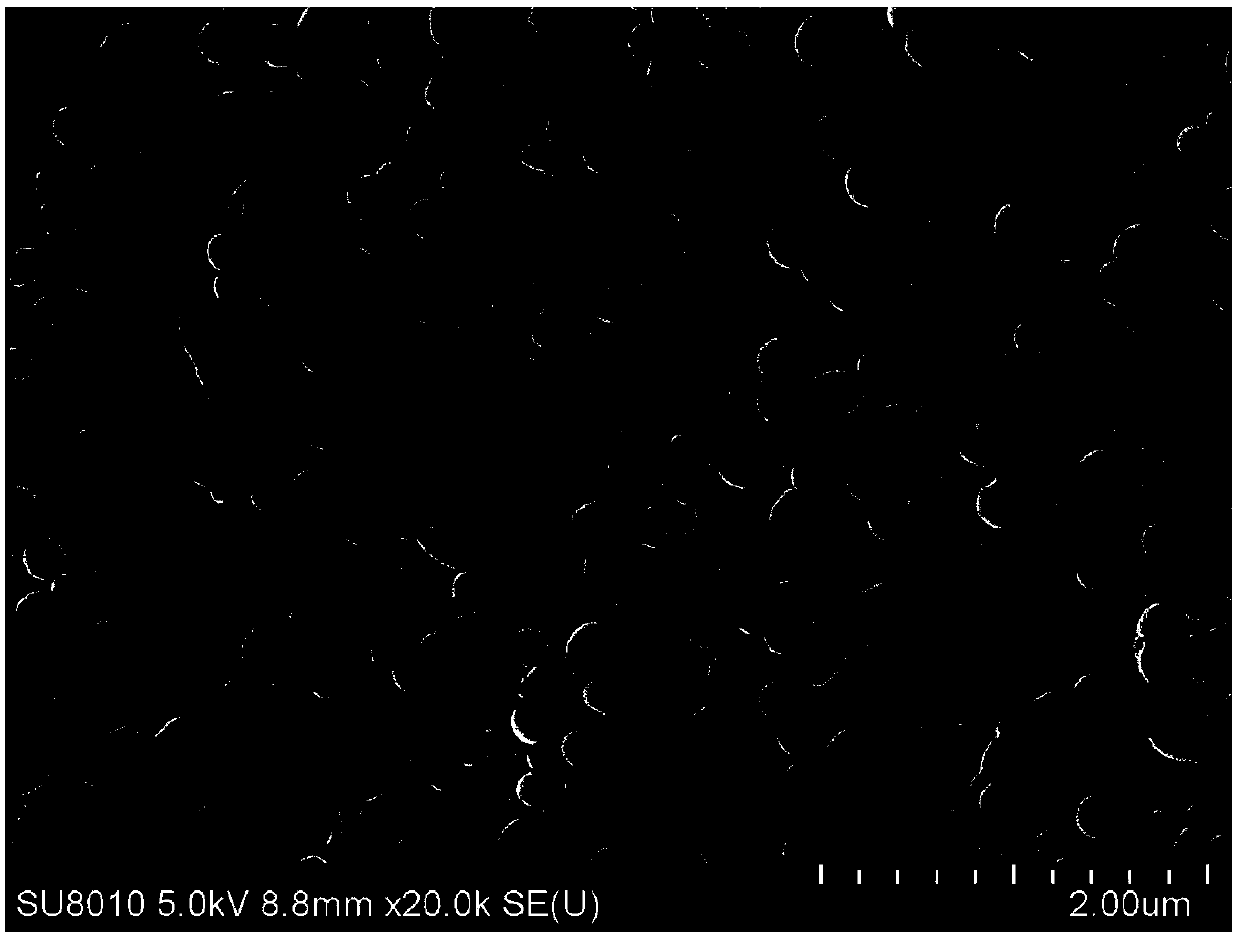

[0085] 2) Preparation of composite diaphragm: The above-mentioned aqueous dispersion is coated on the surface of a 20 μm dry-process biaxially stretched polypropylene diaphragm by means of micro-gravure transfer to obtain a polypropylene composite film containing PVDF with a lamellar structure. Diaphragm (see figure 1 ), where the ...

Embodiment 2

[0087] 1) Preparation of aqueous dispersion containing PVDF powder and / or emulsion swollen by plasticizer and PVDF powder and / or emulsion without plasticizer swelling: water dispersant polyoxyethylene ether and plasticizer After tetrahydrofuran is stirred and dispersed evenly, PVDF powder and / or emulsion (a1) is added to disperse and fully swell, then PVDF powder and / or emulsion (a2) is added to continue to disperse, and finally a binder is added to prepare plasticized Aqueous dispersion of PVDF powder and / or emulsion swollen with plasticizer and PVDF powder and / or emulsion without plasticizer swelling. Wherein, the mass percentage of water is 83wt%; the mass percentage of dispersant is 0.5wt%; the mass percentage of plasticizer is 1.5wt%; the mass percentage of PVDF powder and / or emulsion (a1) The component content is 5wt%; the mass percent of PVDF powder and / or emulsion (a2) is 5wt%; the mass percent of binder is 5wt%.

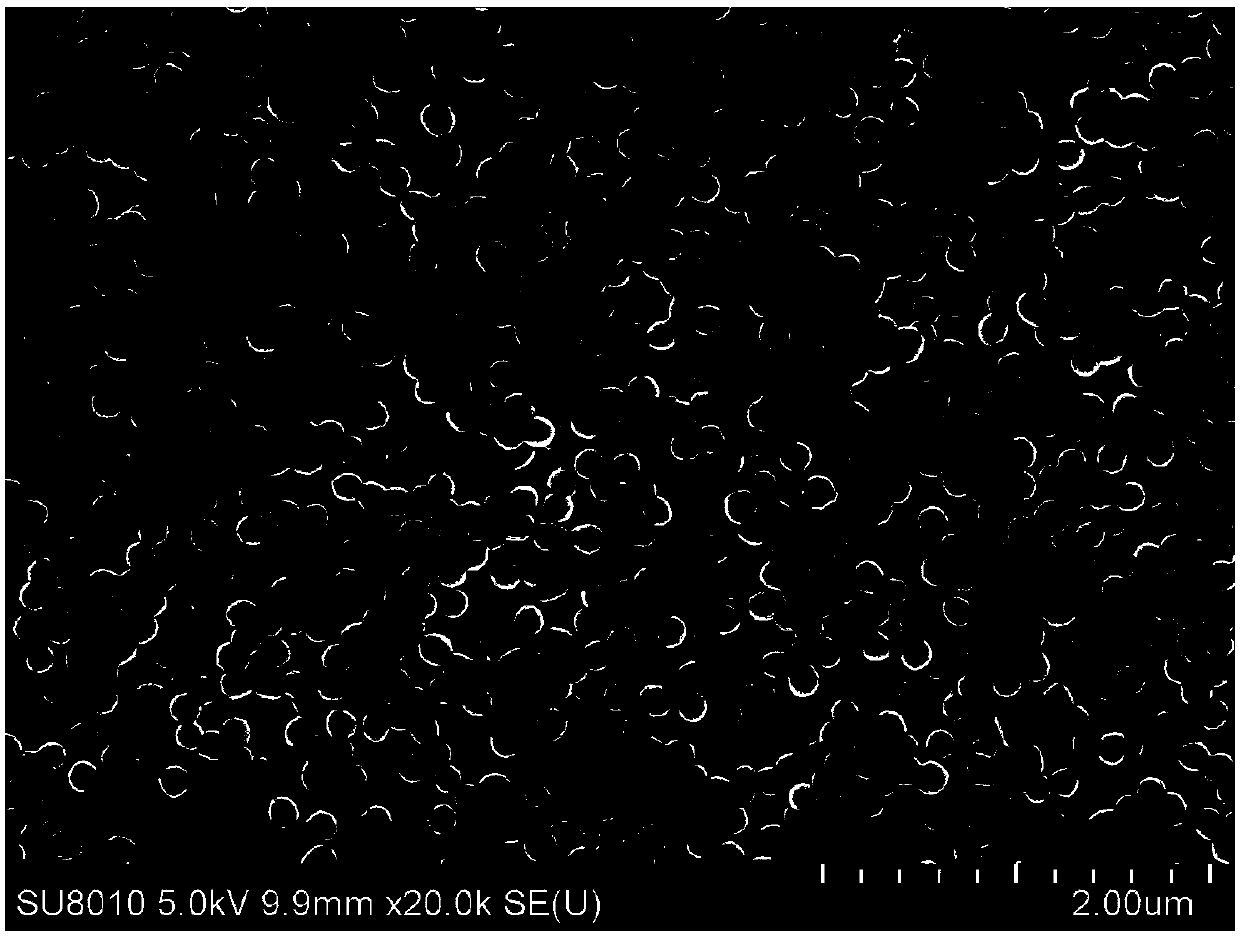

[0088] 2) Preparation of composite diaphragm: The abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com