Safe and healthy functional beef tallow deodorization treatment method

A processing method and functional technology, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of poor removal of fishy substances and low processing efficiency, achieve complete removal of fishy smell, and improve processing efficiency. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

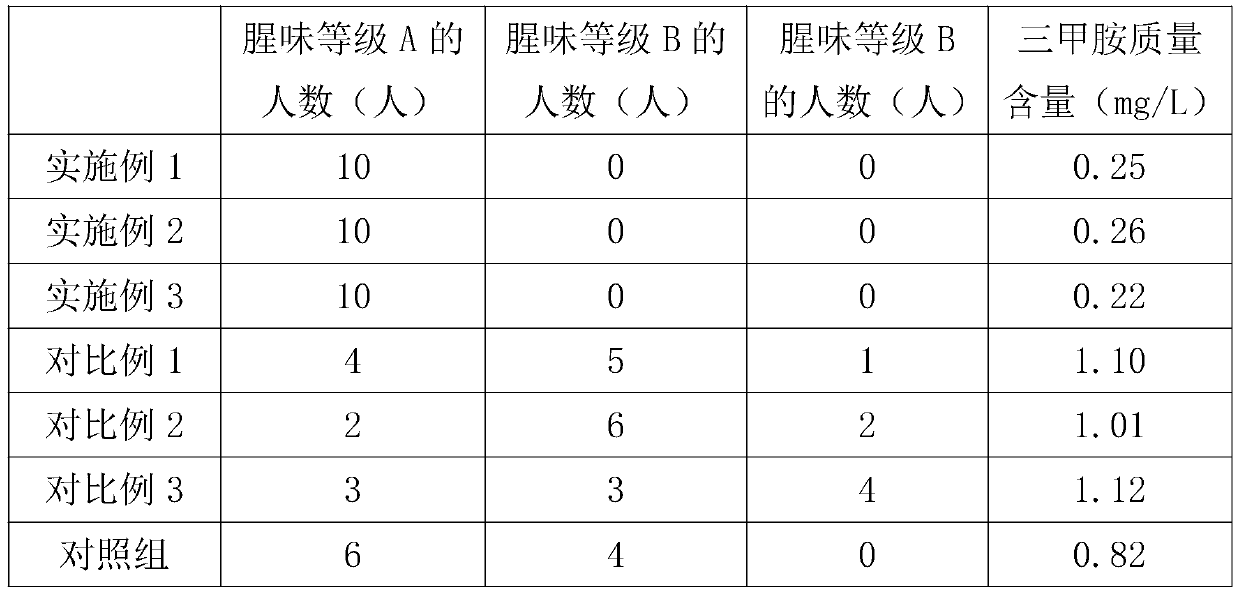

Examples

Embodiment 1

[0017] (1) Weigh 10 parts of tea powder through a 400-mesh sieve and add it to 100 parts of water to disperse evenly to obtain a tea powder suspension, which is sterilized and then added 3 wt % of subtilisine protease, after 12 minutes of shaking culture, the tea powder loaded with Bacillus subtilis alkaline protease was obtained;

[0018] Add 10 parts of the tea powder loaded with Bacillus subtilis alkaline protease to 100 parts of chitosan suspension for cross-linking coating, stir for 0.5h, centrifuge to take the precipitate, and then vacuum dry to obtain Bacillus subtilis Alkaline protease composite carrier, wherein the concentration of chitosan is 1wt%;

[0019] (2) adding the Bacillus subtilis alkaline protease composite carrier into water to prepare a mixed solution with a concentration of 3wt%, adding sodium bicarbonate-potassium dihydrogen phosphate buffer to the mixed solution to adjust the pH value to 7.8 to prepare the fishy liquid;

[0020] (3) Take 100 parts of...

Embodiment 2

[0023] (1) Weigh 10 parts of tea powder that has passed through a 600 mesh sieve and add it to 100 parts of water to disperse evenly to obtain a tea powder suspension, sterilize the tea powder suspension, and then add 5 wt% of subtilisine protease, after 20min shaking culture, the tea powder loaded with Bacillus subtilis alkaline protease was obtained;

[0024] Add 10 parts of the tea powder loaded with Bacillus subtilis alkaline protease to 100 parts of chitosan suspension for cross-linking coating, stir for 1 hour, centrifuge to take the precipitate, and then vacuum-dry to obtain subtilisine Protease composite carrier, wherein the concentration of chitosan is 1.2wt%;

[0025] (2) adding the Bacillus subtilis alkaline protease composite carrier into water to prepare a mixed solution with a concentration of 7wt%, and adding sodium bicarbonate-potassium dihydrogen phosphate buffer to the mixed solution to adjust the pH value to 8.2 to prepare the fishy liquid;

[0026] (3) Ta...

Embodiment 3

[0029] (1) Weigh 10 parts of tea powder that has passed through a 500 mesh sieve and add it to 100 parts of water to disperse evenly to obtain a tea powder suspension, sterilize the tea powder suspension, and then add 4wt% of subtilisine protease, after shaking and culturing for 16 minutes, the tea powder loaded with Bacillus subtilis alkaline protease was obtained;

[0030] Add 10 parts of the tea powder loaded with Bacillus subtilis alkaline protease to 100 parts of chitosan suspension for cross-linking coating, stir for 0.5h, centrifuge to take the precipitate, and then vacuum dry to obtain Bacillus subtilis Alkaline protease composite carrier, wherein the concentration of chitosan is 1.1wt%;

[0031] (2) adding the Bacillus subtilis alkaline protease composite carrier into water to prepare a mixed solution with a concentration of 4wt%, adding sodium bicarbonate-potassium dihydrogen phosphate buffer to the mixed solution to adjust the pH value to 8.0 to prepare the fishy l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com