A lithium metal battery and its application

A lithium metal battery, lithium nitrate technology, applied in lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of battery capacity, expansion performance and cycle performance reduction, lithium metal active side reactions, electrode structure damage and other problems , to achieve the effect of improving cycle performance and Coulomb efficiency, improving expansion and contraction, and improving circulation and expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

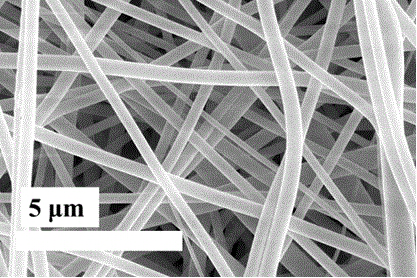

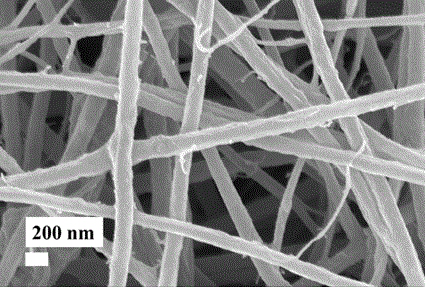

[0057] (1) Preparation of composite structure

[0058] Add 0.022g of lithium nitrate to 20mL of N,N-dimethylformamide, stir to dissolve, add 2.2g of PVDF, and stir at 40°C for 12h until the solution is uniform and clear; transfer the solution to a syringe for static electricity. Spinning to obtain a three-dimensional porous structure loaded with lithium nitrate, which is a composite structure. Electrospinning process parameters: the negative pressure is -4kV, the positive pressure is 18kV, the liquid feed rate is 0.3mL / h, the distance between the collecting plate and the needle is 15 cm-20 cm, and the speed of the collecting drum is 2000 rpm. The composite structure obtained by spinning was placed at room temperature and humidity for 24 hours, and then transferred to a vacuum drying oven for drying at 80°C for 12 hours.

[0059] The thickness of the composite structure is 60 μm, the porosity is 85%, and the average pore size is 800 nm.

[0060] The composite structure prepar...

Embodiment 2

[0070] Preparation of composite structures

[0071] Add 0.044g of lithium nitrate to 20mL of N,N-dimethylformamide and stir to dissolve, then add 2.2g of PVDF, and stir at 40°C for 12h until the solution is uniform and clear; transfer the solution to a syringe as per the implementation Electrospinning was carried out by the method of Example 1 to obtain a three-dimensional porous structure loaded with lithium nitrate, that is, a composite structure. The composite structure obtained by spinning was placed at room temperature and humidity for 24 hours, and then transferred to a vacuum drying oven for drying at 80°C for 12 hours.

[0072] The thickness of the composite structure is 60 μm, the porosity is 85%, and the average pore size is 800 nm.

[0073] The composite structure prepared above was supplemented with lithium by cold pressing, and the thickness of the supplemented lithium layer was 20 μm.

[0074] According to the method of Example 1, the negative pole piece, the p...

Embodiment 3

[0076] Preparation of composite structures

[0077] Add 0.11g of lithium nitrate to 20mL of N,N-dimethylformamide, stir to dissolve, add 2.2g of PVDF, and stir at 40°C for 12h until the solution is uniform and clear; transfer the solution to a syringe as per the implementation Electrospinning was carried out by the method of Example 1 to obtain a three-dimensional porous structure loaded with lithium nitrate, that is, a composite structure. The composite structure obtained by spinning was placed at room temperature and humidity for 24 hours, and then transferred to a vacuum drying oven for drying at 80°C for 12 hours.

[0078] The thickness of the composite structure is 60 μm, the porosity is 85%, and the average pore size is 800 nm.

[0079] The composite structure prepared above was supplemented with lithium by cold pressing, and the thickness of the supplemented lithium layer was 20 μm.

[0080] According to the method of Example 1, the negative pole piece, the positive p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com