A kind of composite soil remediation agent and its preparation method and application

A soil remediation and reagent technology, applied in the field of soil remediation, can solve problems such as complex components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

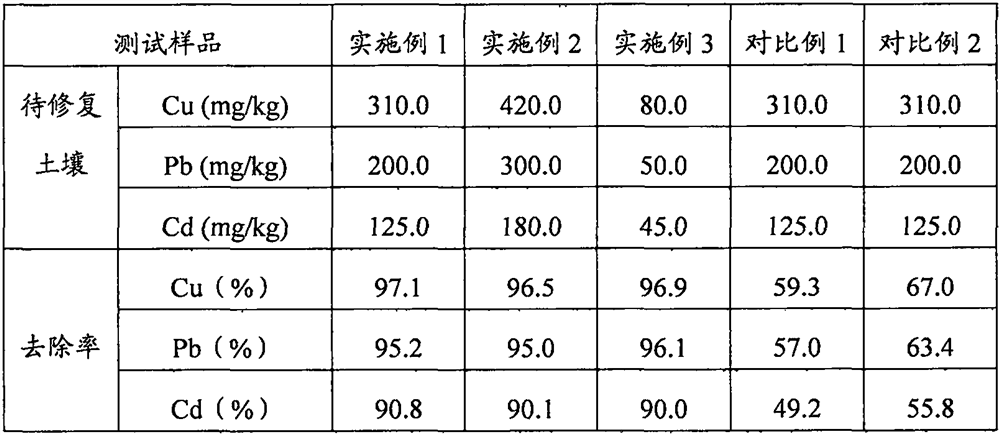

Examples

preparation example Construction

[0023] In the present invention, the preparation method of described biochar preferably comprises the following steps:

[0024] Heat-treat the raw materials for the preparation of biochar to obtain primary carbon materials;

[0025] The primary carbon material is impregnated in a solution including potassium permanganate and nitric acid for modification to obtain biochar.

[0026] The invention heat-treats raw materials for preparing biochar to obtain primary carbon materials. Before the heat treatment, the present invention preferably pretreats the raw materials for the preparation of biochar. The pretreatment includes crushing and drying. The crushing can obtain scraps below 100 mesh, and the drying can control the moisture content at 5 % or less is fine.

[0027] In the present invention, the heat treatment temperature is preferably 280-300°C, more preferably 285-295°C, and more preferably 287-293°C; the heat treatment time is preferably 2-4h, specifically 2.5h, 3h, 3.5h...

Embodiment 1

[0044] Preparation of biochar: crush corn stalks, pass through a 100-mesh sieve, then heat-treat at 285°C for 2 hours, and then place the obtained primary carbon material (50g) in a mixture of potassium permanganate and nitric acid (KMnO 4 The concentration is 0.15mol / L, HNO 3 The mass concentration is 40% and the volume is 500mL), kept at 80°C for 2h, extracted, washed 3 times with deionized water, and dried naturally to obtain biochar.

[0045] According to the dosage shown in Table 1, the quicklime, sodium humate and sodium polyacrylate are first mixed in a mixer, and then the rest of the materials are added, and the composite soil repair agent is obtained after mixing evenly.

Embodiment 2

[0047] Preparation of biochar: crush corn stalks, pass through a 100-mesh sieve, then heat-treat at 290°C for 2.5 hours, and then place the obtained primary carbon material (50g) in a mixture of potassium permanganate and nitric acid Medium (KMnO 4 The concentration is 0.1mol / L, HNO 3 The mass concentration is 45% and the volume is 500mL), incubated at 80°C for 2h, filtered, washed and dried to obtain biochar; the rest of the steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com