Production method and application of stalk fermentation feed

A technology of fermented feed and production method, which is applied in application, animal feed, animal feed, etc. It can solve the problems of poor application effect, less metabolites, and incomplete fermentation, and achieve good effect, long shelf life, and rapid and thorough fermentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

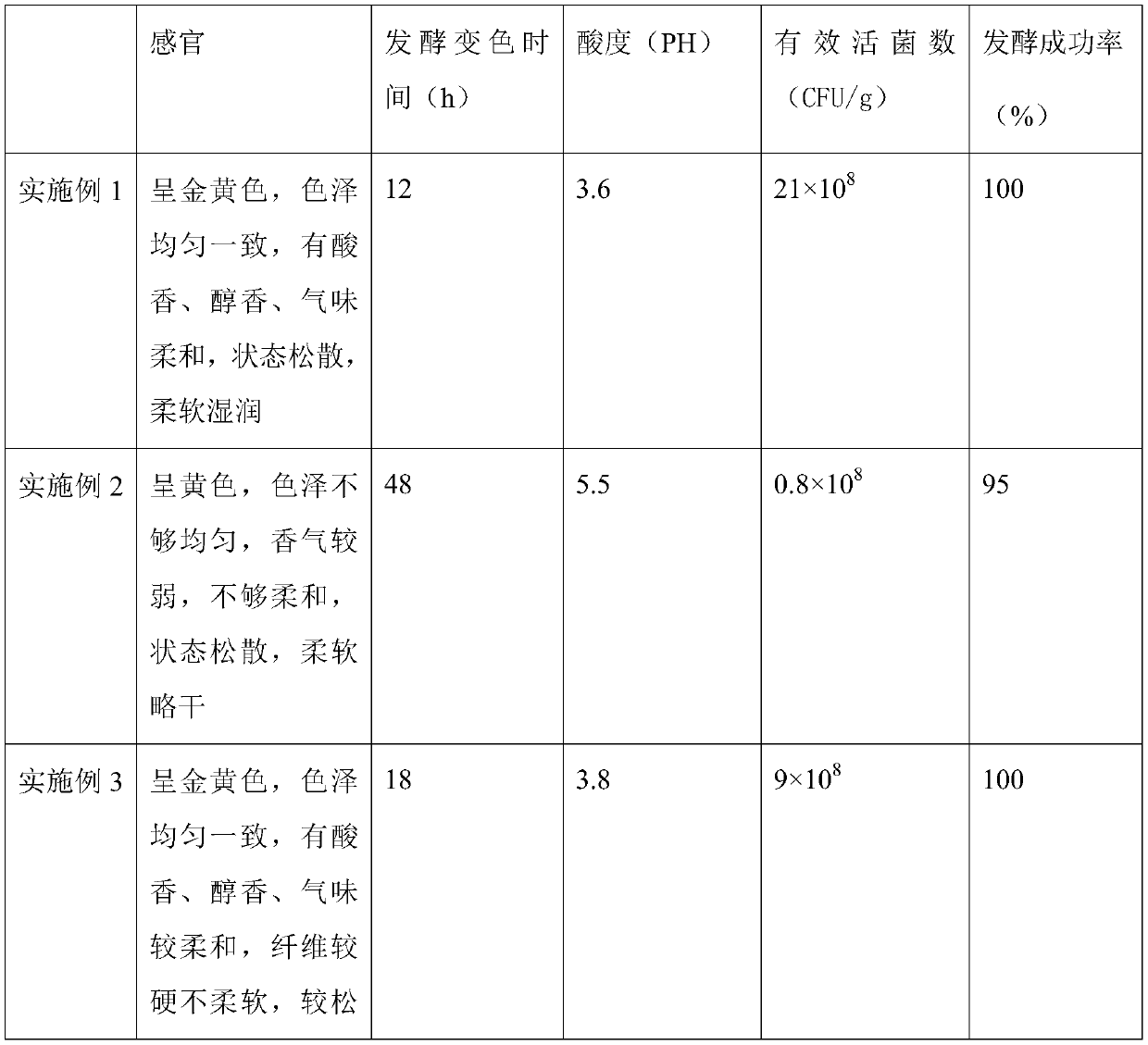

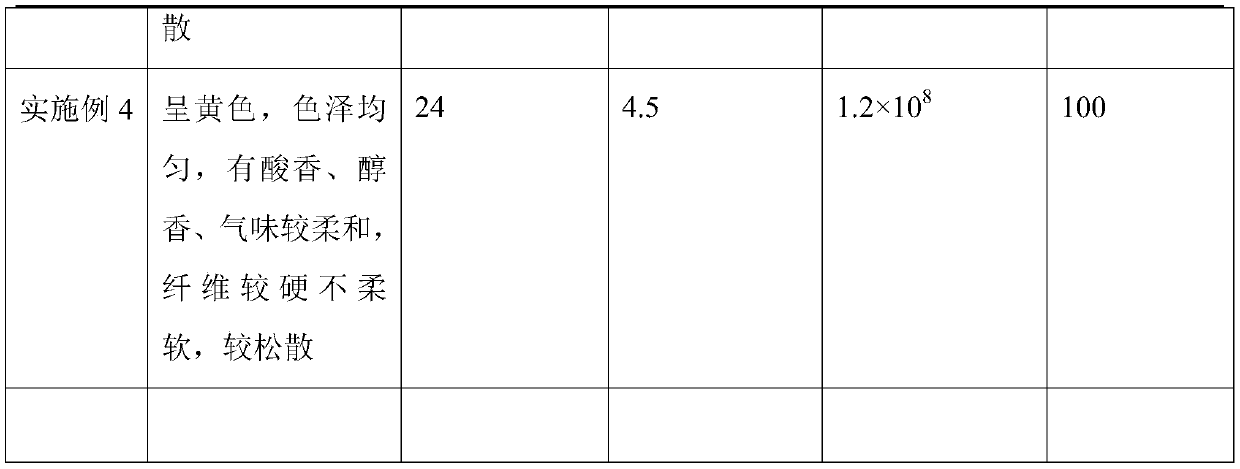

Examples

specific Embodiment approach 1

[0015] Specific embodiment one: the production method of a kind of stalk fermented feed of the present embodiment, it is carried out according to the following steps:

[0016] 1. Preparation of straw: dry or dry the straw, remove impurities after the coarse powder, and then carry out secondary crushing, and then carry out molding to make straw particles of 8-18mm, and the granulation temperature is 90-110°C; finally The straw particles are pulverized, sieved, and made into straw powder for later use;

[0017] 2. Preparation of the starter: dissolve the starter in water and activate it for later use;

[0018] 3. Weigh 350-390 parts by weight of straw powder and 50 parts by weight of dry corn flour and mix evenly; then add the activated starter, add water and stir to make the moisture content of the material 58-65%; Palletize in gas fermentation bags, press the stack with heavy objects, discharge the gas in the fermentation bags, and ferment for 7 days at a temperature of 28-32...

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment is different from Embodiment 1 in that: the coarsely ground straw is removed by a drum sieve with an aperture of 10 mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment is different from Embodiment 1 in that: the secondary crushing is carried out by using a 10 mm sieve bottom hammer mill. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com