Artificial lens containing antibiotics and preparation method thereof

An intraocular lens and antibiotic technology, applied in the direction of prosthesis, tissue regeneration, medical science, etc., can solve the problem that the strength and transparency of intraocular lens cannot be taken into account, and achieve short production process time, good biocompatibility, and light transmission. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

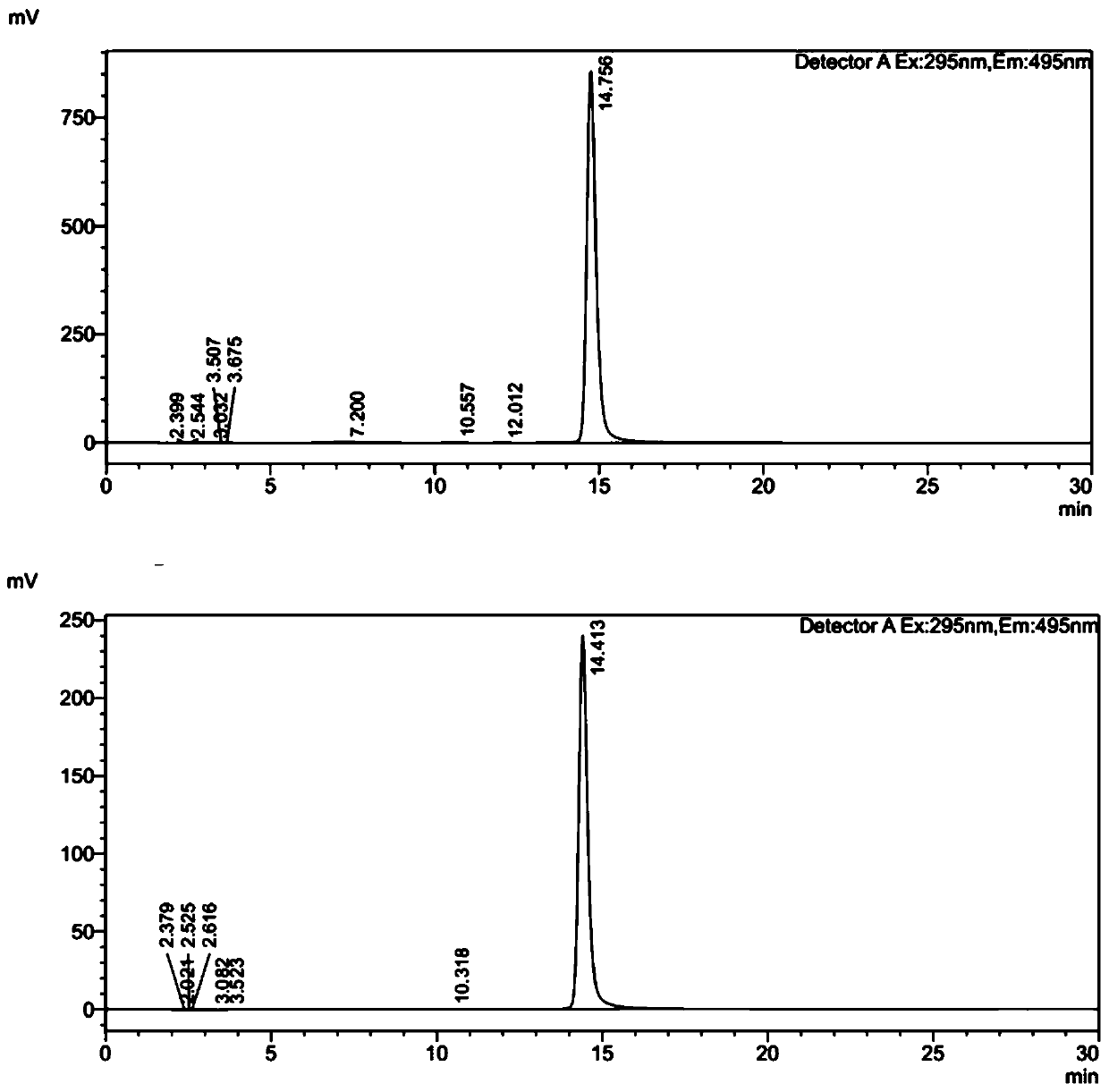

Image

Examples

Embodiment 1

[0033] Example 1: In this example, a foldable intraocular lens containing gatifloxacin was prepared.

[0034] The preparation method comprises the following steps:

[0035] (1) Prepare a polyurethane acrylate prepolymer: the molar ratio of isocyanate: polyether polyol: hydroxy acrylate is 2:1:2.1. The reaction vessel is a 250ml four-necked flask, which is connected with an overhead mechanical stirrer, a reflux condenser, a constant pressure dropping funnel, a thermometer, and nitrogen gas. The heating device is an oil bath. 4.4456 g of isophorone diisocyanate and 0.0086 g of a catalyst dibutyltin dilaurate were put into a four-necked flask, and 10.0000 g of polyethylene glycol-1000 was added dropwise at 60°C. After reacting for 2 hours, slowly add 2.4385g of 2-hydroxypropyl acrylate and 0.0273g of hydroquinone, raise the temperature to 80°C and continue the reaction for 3 hours to obtain a transparent viscous liquid, which should be sealed and stored in a cool place.

[0036...

Embodiment 2

[0041] Example 2: In this example, a foldable intraocular lens containing levofloxacin was prepared.

[0042] The preparation method comprises the following steps:

[0043] (1) Prepare a polyurethane acrylate prepolymer: the molar ratio of toluene diisocyanate: polytetrahydrofuran-1000: 2-hydroxyethyl acrylate is 5:1:8.1. The reaction vessel is a 250ml four-necked flask, which is connected with an overhead mechanical stirrer, a reflux condenser, a constant pressure dropping funnel, a thermometer, and nitrogen gas. The heating device is an oil bath. Put 9.4057g of 2-hydroxyethyl acrylate and 0.0930g of hydroquinone into a four-neck flask, add 8.7100g of toluene diisocyanate dropwise at 30°C, and react for 5 hours, then slowly add 10.0000g of polytetrahydrofuran-1000, and raise the temperature The reaction was continued at 40°C for 6 hours to obtain a transparent viscous liquid, which was sealed and stored in a cool place.

[0044] (2) Preparation of photocurable resin compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com