Flake silver powder prepared by means of chemical reduction method and preparation method thereof

A technology of flake silver powder and reduction method, which is applied in the field of materials, can solve the problems of easy introduction of impurity technical indicators, high yield of ball milling method, difficulty in maintaining consistency, etc., and achieve high uniformity of shape and particle size, low cost and excellent quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

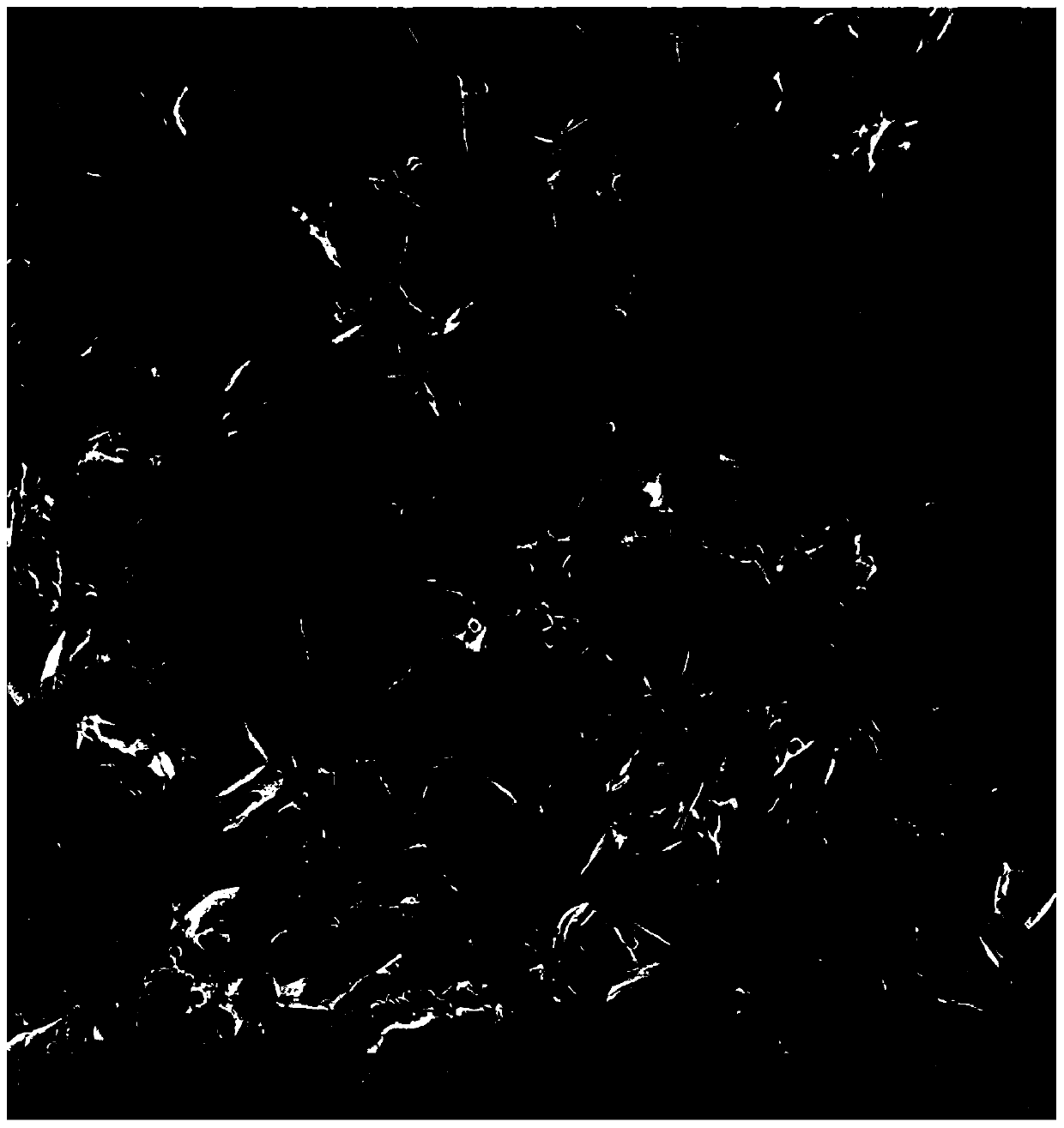

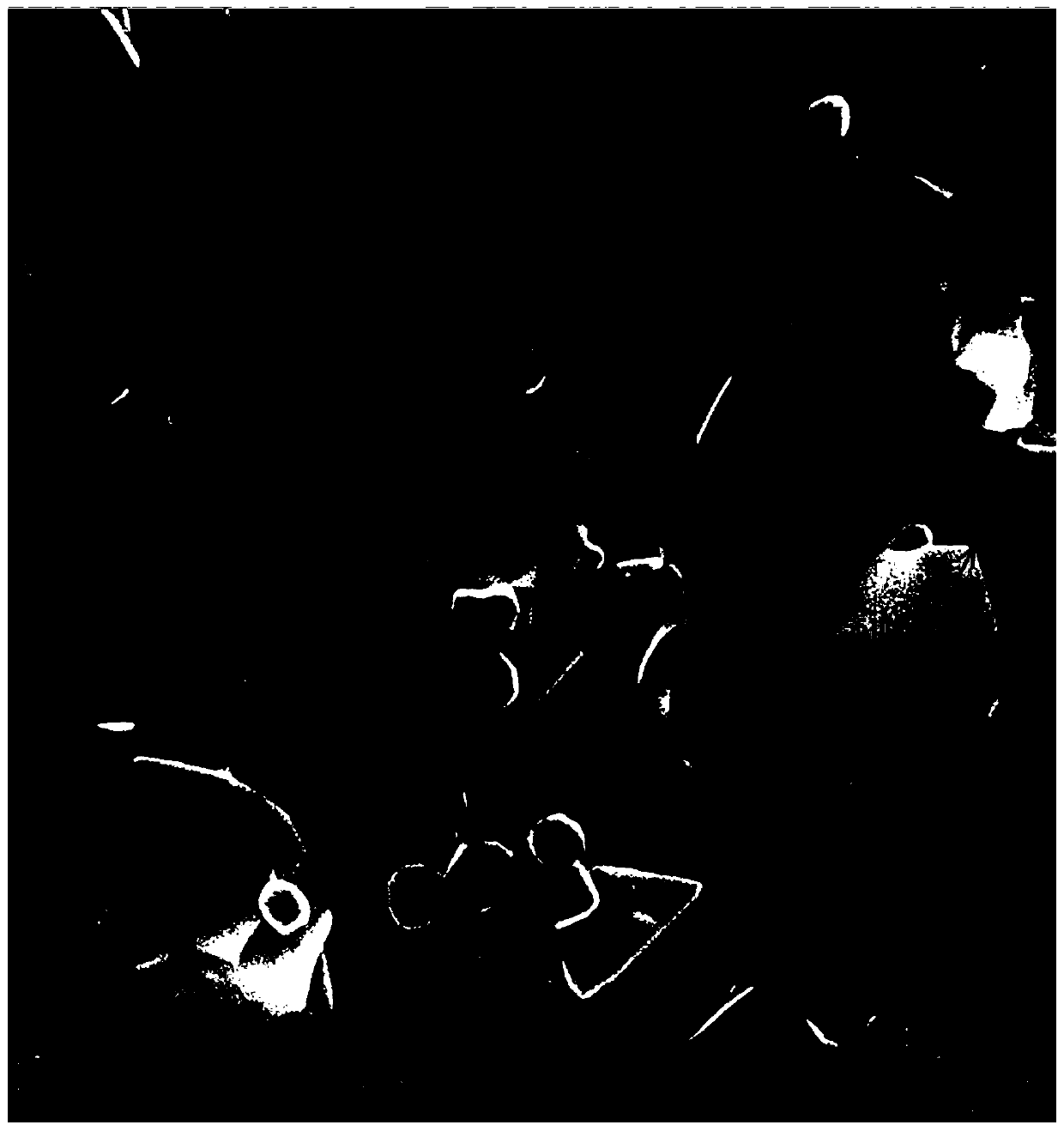

Image

Examples

Embodiment 1

[0031] A method for preparing flake silver powder by a chemical reduction method, comprising:

[0032] Step 1, select and weigh each raw material.

[0033] Step 2, prepare the reduction solution: add 1500ml of pure water into a 5L beaker, place it in a constant temperature water bath with circulation heating function, set the temperature at 40°C, and add acacia to the beaker after the temperature reaches the set value Stir 62.5g of rubber powder, 30g of potassium sulfate, 80g of hydrogen peroxide, and 100g of vitamin C to fully dissolve them, and then use nitric acid to adjust the pH of the solution to 3.5-4, and set aside.

[0034] Step 3, prepare silver nitrate solution: add 1500ml of pure water into a 5L beaker, then add 300g of silver nitrate to stir and dissolve, then adjust the pH value to 3.5-4, and set aside. Adjust the pH of the solution with nitric acid.

[0035] Step 4, use a peristaltic pump to add the silver nitrate solution obtained in step 3 to the reducing solu...

Embodiment 2

[0039] A method for preparing flake silver powder by a chemical reduction method, comprising:

[0040] Step 1, select and weigh each raw material.

[0041] Step 2, prepare the reduction solution: add 1200ml of pure water into a 5L beaker, place it in a constant temperature water bath with circulation heating function, set the temperature at 40°C, and add acacia to the beaker after the temperature reaches the set value Stir 60g of rubber powder, 25g of potassium sulfate, 70g of hydrogen peroxide, and 90g of vitamin C to fully dissolve them, then use nitric acid to adjust the pH of the solution to 3.5-4, and set aside.

[0042] Step 3, prepare silver nitrate solution: add 1200ml of pure water into a 5L beaker, then add 250g of silver nitrate to stir and dissolve, then adjust the pH value to 3.5-4, and set aside. Adjust the pH of the solution with nitric acid.

[0043] Step 4, use a peristaltic pump to add the silver nitrate solution obtained in step 3 to the reducing solution ...

Embodiment 3

[0047] A method for preparing flake silver powder by a chemical reduction method, comprising:

[0048] Step 1, select and weigh each raw material.

[0049] Step 2, prepare the reduction solution: add 1600ml of pure water into a 5L beaker, place it in a constant temperature water bath with circulation heating function, set the temperature at 40°C, and add acacia to the beaker after the temperature reaches the set value Stir 65g of rubber powder, 35g of potassium sulfate, 90g of hydrogen peroxide, and 120g of vitamin C to make them fully dissolve, then use nitric acid to adjust the pH of the solution to 3.5-4, and set aside.

[0050] Step 3, prepare silver nitrate solution: add 1600ml of pure water into a 5L beaker, then add 350g of silver nitrate to stir and dissolve, then adjust the pH value to 3.5-4, and set aside. Adjust the pH of the solution with nitric acid.

[0051] Step 4, use a peristaltic pump to add the silver nitrate solution obtained in step 3 to the reducing sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com