Method for controlling mutual transformation between calcite and vaterite by using calcium source concentration

A technology of calcite and vaterite, applied in the field of biomimetic materials, achieves the effects of high repeatability, fast response speed, and low environmental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

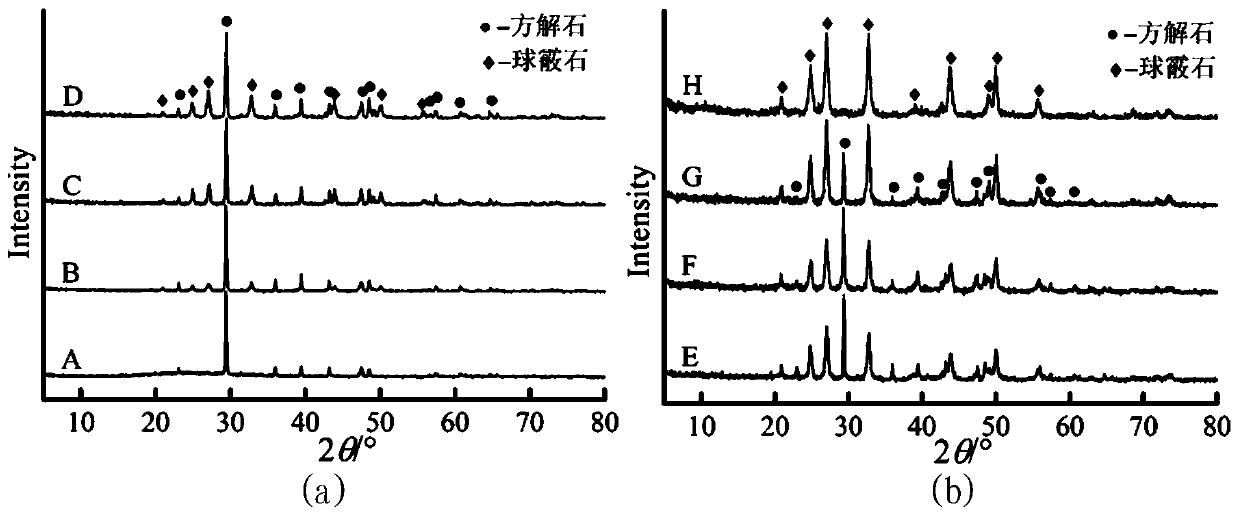

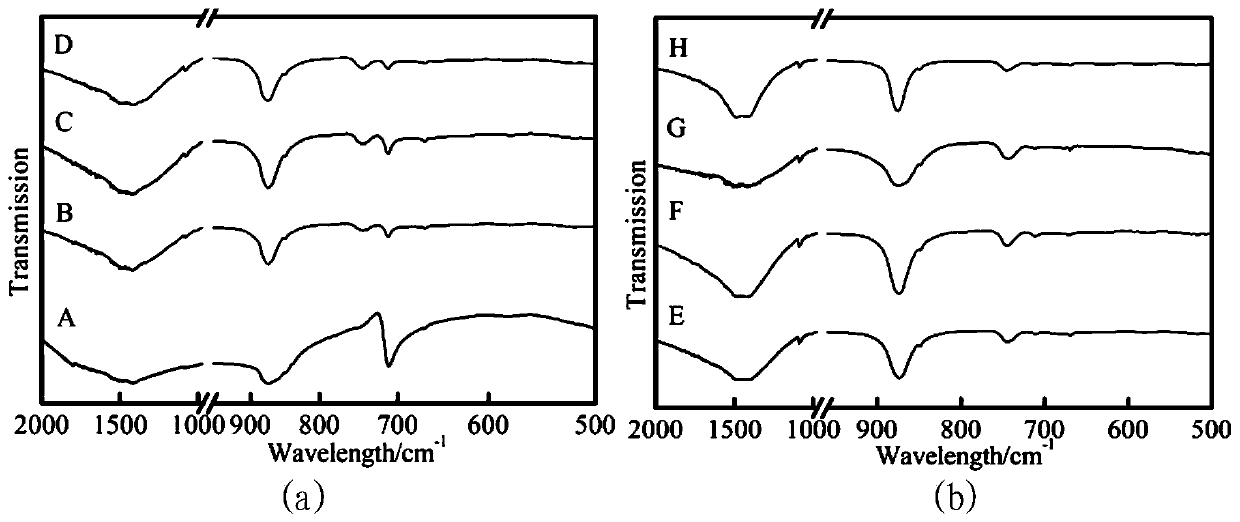

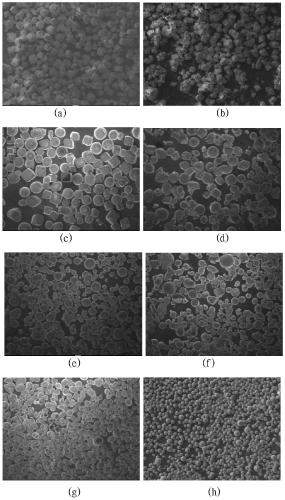

Embodiment 1

[0041] Step 1: inoculate S.pasteurii on the culture medium, and culture it in a shaking incubator at 30°C and 100r / min for 48 hours to obtain a bacterial liquid; wherein, the culture medium includes yeast extract 10~ 30g / L, ammonium sulfate 15g / L, the pH of the medium is 7-9.5;

[0042] Step 2: configure the mixed solution of urea and calcium acetate monohydrate as a nutrient salt solution, wherein the concentration of urea is 0.5mol / L, and the concentration of calcium acetate monohydrate is 0.025mol / L;

[0043] Step 3: Prepare 0.2g / L urease solution (urease activity is 137u / mg), add the urease solution into the nutrient salt solution, and the volume ratio of the nutrient salt solution to the urease solution is 9:1;

[0044] Step 4: Add the bacterial liquid to the mixed solution of urease and nutrient salt, the volume ratio of the bacterial liquid to the mixed solution is 1:10, shake evenly, and stand at 20°C for 72 hours;

[0045] Step 5: Ultrasonic treatment at 20-40°C for 30...

Embodiment 2

[0051] Step 1: inoculate S.pasteurii on the culture medium, and culture it in a shaking incubator at 30°C and 100r / min for 48 hours to obtain a bacterial liquid; wherein, the culture medium includes yeast extract 10~ 30g / L, ammonium sulfate 15g / L, the pH of the medium is 7-9.5;

[0052] Step 2: configure the mixed solution of urea and calcium acetate monohydrate as a nutrient salt solution, wherein the concentration of urea is 0.5mol / L, and the concentration of calcium acetate monohydrate is 0.1mol / L;

[0053] Step 3: Prepare 0.2g / L urease solution (urease activity is 137u / mg), add urease solution into nutrient salt solution, the volume ratio of nutrient salt solution to urease solution is 8:1;

[0054] Step 4: Add the bacterial liquid to the mixed solution of urease and nutrient salt, the volume ratio of the bacterial liquid to the mixed solution is 1:10, shake evenly, and stand at 20°C for 72 hours;

[0055] Step 5: Ultrasonic treatment at 20-40°C for 30min-1h to obtain a s...

Embodiment 3

[0061] Step 1: inoculate S.pasteurii on the culture medium, and culture it in a shaking incubator at 30°C and 100r / min for 48 hours to obtain a bacterial liquid; wherein, the culture medium includes yeast extract 10~ 30g / L, ammonium sulfate 15g / L, the pH of the medium is 7-9.5;

[0062] Step 2: configure the mixed solution of urea and calcium acetate monohydrate as a nutrient salt solution, wherein the concentration of urea is 0.5mol / L, and the concentration of calcium acetate monohydrate is 0.3mol / L;

[0063] Step 3: Prepare 0.2g / L urease solution (urease activity is 110u / mg), add urease solution into nutrient salt solution, the volume ratio of nutrient salt solution to urease solution is 9:1;

[0064] Step 4: Add the bacterial liquid to the mixed solution of urease and nutrient salt, the volume ratio of the bacterial liquid to the mixed solution is 1:10, shake evenly, and stand at 10°C for 72 hours;

[0065] Step 5: Ultrasonic treatment at 20-40°C for 30min-1h to obtain a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com