Porous tantalum-based oxynitride ceramic, and preparation method thereof

A nitride ceramic and oxynitride technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of long sintering time, low purity of oxynitride ceramics, and low heat transfer efficiency, and achieve heating and heat transfer. High efficiency, high open porosity, high radiation heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

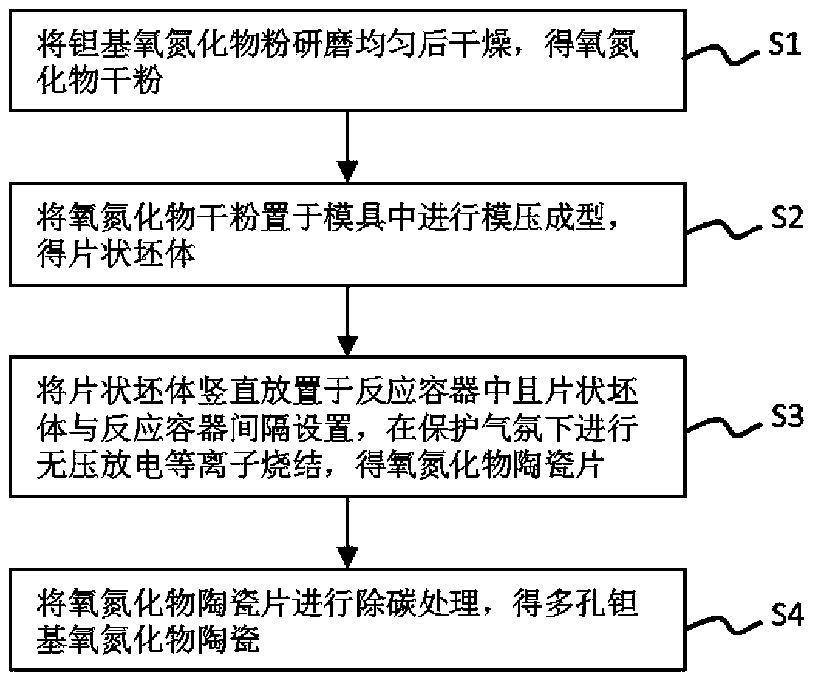

[0035] Such as figure 1 As shown, a preparation method of the porous tantalum-based oxynitride ceramics of this embodiment comprises the following steps:

[0036] (1) Take 1g of BaTaO with a purity of 98% 2 The N powder was ground evenly and dried at 110°C for 12 hours to obtain BaTaO 2 N dry powder.

[0037] (2) BaTaO obtained in step (1) 2 N dry powder was placed in a stainless steel mold and held at a pressure of 100MPa for 60s to obtain BaTaO 2 N round flake green body.

[0038] (3) BaTaO obtained in step (2) 2 The N disc-shaped body is placed vertically and centered in the reaction vessel 1 (a closed graphite crucible in this embodiment) and arranged at intervals. The pressureless discharge plasma sintering is carried out in a nitrogen atmosphere, and the temperature is raised to 1250°C, keep it warm for 1min, and then cool to room temperature with the furnace to get BaTaO 2 N ceramic sheet.

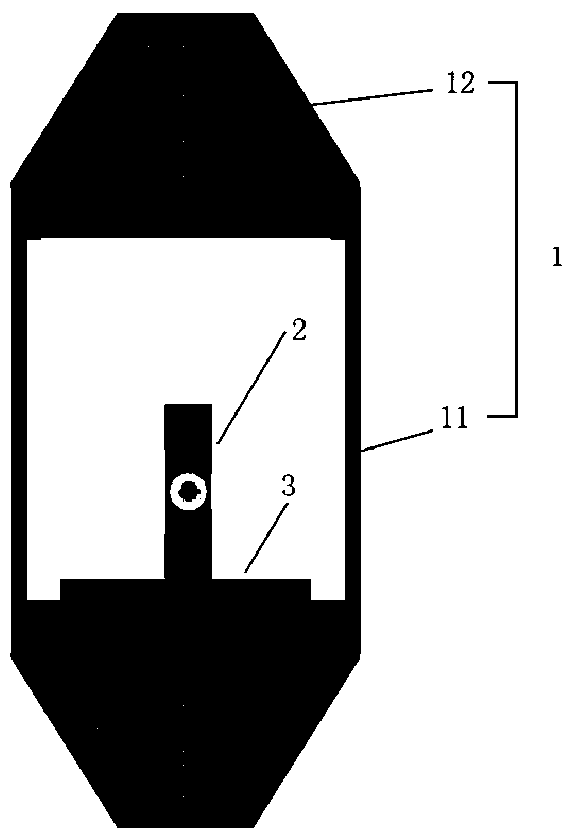

[0039] Such as figure 2 As shown, in this example, BaTaO 2 The N ci...

Embodiment 2

[0054] A preparation method of the porous tantalum-based oxynitride ceramics of this embodiment, comprising the following steps:

[0055] (1) Take 1g of BaTaO with a purity of 98% 2 The N powder was ground evenly and dried at 110°C for 12 hours to obtain BaTaO 2 N dry powder.

[0056] (2) Put the powder obtained in step (1) into a stainless steel mold, and hold the pressure at 100MPa for 60s to obtain BaTaO 2 N round flake green body.

[0057] (3) BaTaO obtained in step (2) 2 The N disc-shaped body is placed vertically and centered in the reaction vessel 1 (a closed graphite crucible in this embodiment) and arranged at intervals. The pressureless discharge plasma sintering is carried out in a nitrogen atmosphere, and the temperature is raised to 1300°C, keep it warm for 1min, and then cool to room temperature with the furnace to get BaTaO 2 N ceramic sheet.

[0058] In this example, BaTaO 2 The placement method of the N-disc blank is the same as that of Example 1.

[0...

Embodiment 3

[0062] A preparation method of the porous tantalum-based oxynitride ceramics of this embodiment, comprising the following steps:

[0063] (1) Take 1g of BaTaO with a purity of 98% 2 The N powder was ground evenly and dried at 110°C for 12 hours to obtain BaTaO 2 N dry powder.

[0064] (2) Put the powder obtained in step (1) into a stainless steel mold, and hold the pressure at 100MPa for 60s to obtain BaTaO 2 N round flake green body.

[0065] (3) BaTaO obtained in step (2) 2 N disc-shaped blanks are vertically placed in the center of the reaction vessel 1 (this embodiment is a closed graphite crucible) and arranged at intervals, and the pressureless discharge plasma sintering is carried out in a nitrogen atmosphere, and the temperature is raised at a heating rate of 100°C / min. 1300°C, keep it warm for 1min, and then cool to room temperature with the furnace to get BaTaO 2 N ceramic sheet.

[0066] In this example, BaTaO 2 The placement method of the N-disc blank is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com